PumpMan® Expands Southern California Coverage with Acquisition of Ransom Pump & Supply in Ramona, California PumpMan®, a leader in the sales, service, maintenance, and repair of pumps, motor, and control systems in the United States, announces the acquisition of Ransom Pump & Supply based in Ramona, CA. Ransom Pump & Supply will join PumpMan’s Read more

Pumps

PumpMan® Expands Southern California Coverage with Acquisition of Ransom Pump & Supply in Ramona, California

PumpMan®, a leader in the sales, service, maintenance, and repair of pumps, motor, and control systems in the United States, announces the acquisition of Ransom Pump & Supply based in Ramona, CA. Ransom Pump & Supply will join PumpMan’s Baldwin Park-based PumpMan SoCal and PumpMan San Diego in serving, the commercial, industrial, municipal, agriculture and multi-unit residential pump systems in Los Angeles, Orange, San Bernardino, Riverside, San Diego, and Imperial counties.

PumpMan®, a leader in the sales, service, maintenance, and repair of pumps, motor, and control systems in the United States, announces the acquisition of Ransom Pump & Supply based in Ramona, CA. Ransom Pump & Supply will join PumpMan’s Baldwin Park-based PumpMan SoCal and PumpMan San Diego in serving, the commercial, industrial, municipal, agriculture and multi-unit residential pump systems in Los Angeles, Orange, San Bernardino, Riverside, San Diego, and Imperial counties.

Ransom Pump & Supply designs, services, repairs, and installs complete residential and commercial well based freshwater systems. These complete systems include pumps, motors, system controls, water storage and pressure boosters, and include generators or solar panels as back-up power supplies to ensure service reliability.

“Since 1924 Ransom Pump & Supply has been serving the agricultural, municipal, and residential markets throughout Ramona and San Diego County California. Our focus is to provide the highest quality of customer service, as well as the design of efficient productive pump and electrical systems” – Sommer Adams, General Manager Ransom Pump & Supply

“PumpMan’s goal is to expand our presence throughout Southern California with multiple locations and expanded service capabilities. Ransom’s focus on well pumping systems is a nice complement to our Pumpman SoCal capabilities and provides the local community with access to groundwater water supplies as California continues to experience severe drought conditions. We will be expanding Ransom’s staffing levels and capacity as market demand requires” said Donald Devine CEO of PumpMan, LLC.

Ransom Pump & Supply will continue operate with its full staff of pump technicians, field service mechanics, and administration personnel at the facility located at 533 B St, Ramona, CA 92065 24/7 Service is available 760-789-5955.

More information at: www.ransompump.com, www.pumpman.com

“Any day building custom mechanical rooms is a great day,” says Tyler Dynes (@dyneshvac), lead installer—with a specialty in hydronics—for Farr Mechanical Corp., greater Toronto area. You see, for Dynes, the most rewarding part of his work is seeing the finished install and hearing the customer say, “this is the nicest room in the house.” Read more

“Any day building custom mechanical rooms is a great day,” says Tyler Dynes (@dyneshvac), lead installer—with a specialty in hydronics—for Farr Mechanical Corp., greater Toronto area. You see, for Dynes, the most rewarding part of his work is seeing the finished install and hearing the customer say, “this is the nicest room in the house.”

In fact, Dynes loves what he does so much, one of his bucket list items is building his own home with a custom hydronic system.

Dynes’ rise into the trades started right out of high school where he began a career in automotive mechanics. After a few years in the field, he soon realized it just wasn’t for him. After speaking to someone at a local fuel/HVAC company, Dynes decided to give working for them a try. Several of his friends were in the industry already and encouraged him to enter the trade. “I worked with that company for about 11 years, learning everything I could in the residential HVAC field. It was here I became a gas fitter, oil burner and started my AC apprenticeship,” says Dynes.

Tyler with Brandon Farr (l), owner of Farr Mechanical.

One of my Dynes’ first mentors was a seasoned tech named Chris who Dynes trained under for five years at that first HVAC company. I also follow the careers of Eric Aune (@mechanicalhub), Mike Flynn (@flynnstone1), Don Taylor (@dontaylor53) and Aaron Bond (@bond_aaron) closely on Instagram. “They inspire me to push myself and learn more about all the different aspects of the trade. I still look up to them and chat with them from time to time,” says Dynes.

Dynes hadn’t considered himself a role model, just someone who takes a lot of pride in what he does. “I hope that I can encourage people to join the trade, and for those already in it, to push themselves to learn new skills. I would love for people to look at my work and be able to ask questions to help them learn everything I have and beyond,” says Dynes.

And with that, social media has allowed Dynes to grow professionally and personally as he loves the relationships that he’s built through it. Dynes is amazed at the support and encouragement he’s received over the last few years through his Instagram posts and stories. “It has such a great community of people from all trades supporting each other,” says Dynes.

And with that, social media has allowed Dynes to grow professionally and personally as he loves the relationships that he’s built through it. Dynes is amazed at the support and encouragement he’s received over the last few years through his Instagram posts and stories. “It has such a great community of people from all trades supporting each other,” says Dynes.

Yet social media can become addicting, says Dynes, and it can be hard to step away. “After I get home, there are usually questions or conversations that happen through Instagram about my posted installs or other people looking for advice. I try to help when I can, but I know it’s important to put my phone down and spend time with my family, which can be going to the cottage with his family and riding his dirt bike,” says Dynes.

Over the past decade, there is no debating social media has become a place where contractors can show off their work and wares, and connect. This should help enhance the trades. “We need to showcase the fun side of trades and that no day is ever the same. There are so many areas that you can excel or specialize in, and we need to make that more known to people. It’s a hard work, fast-paced environment, but it’s so rewarding when you get the freedom to be creative,” says Dynes.

Over the past decade, there is no debating social media has become a place where contractors can show off their work and wares, and connect. This should help enhance the trades. “We need to showcase the fun side of trades and that no day is ever the same. There are so many areas that you can excel or specialize in, and we need to make that more known to people. It’s a hard work, fast-paced environment, but it’s so rewarding when you get the freedom to be creative,” says Dynes.

Taco Comfort Solutions donated $25,000 to Tunnel to Towers Foundation during an event held on June 15 at Wales Darby’s Islandia, N.Y. facility. Taco teamed up with their New York manufacturer’s rep, Wales Darby, to run a contractor promotion in the Long Island area supporting Tunnel to Towers. Taco donated proceeds from Taco heating circulators Read more

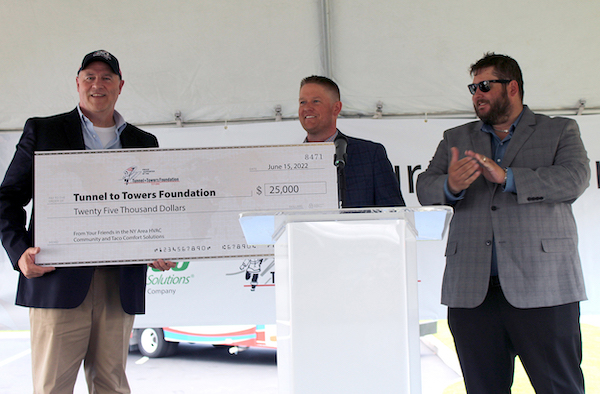

Taco Comfort Solutions donated $25,000 to Tunnel to Towers Foundation during an event held on June 15 at Wales Darby’s Islandia, N.Y. facility.

From left to right, Tunnel to Towers Foundation representative Andrew McClure receives a check for $25,000 from Taco Comfort Solutions’ Benjamin White, Manager, Supply Chain, and John White, III, Sr. Vice President, OEM Sales.

Taco teamed up with their New York manufacturer’s rep, Wales Darby, to run a contractor promotion in the Long Island area supporting Tunnel to Towers. Taco donated proceeds from Taco heating circulators sold during a four-month period to Tunnel to Towers.

Tunnel to Towers Foundation supports families of fallen and severely injured military and first responders by providing mortgage-free homes.

By Norman Hall A competitor recently asked how we can afford to spend so much time and money training our employees and our customers. My response is, “How can you afford not to train your people?” I would argue that education should be a prominent expense item for all contractors, wholesalers, and representatives in the Read more

By Norman Hall

A competitor recently asked how we can afford to spend so much time and money training our employees and our customers. My response is, “How can you afford not to train your people?” I would argue that education should be a prominent expense item for all contractors, wholesalers, and representatives in the HVAC and plumbing world. In this industry, where product and technical information can feel like a tsunami, customers rely on us to act as trusted advisors guiding them to the best solution. Our staff cannot simply exist as a walking, talking brochure. Arming our people with the knowledge and empowerment to think critically and to act with integrity has resulted in a thriving business and a dedicated customer base here at R.L. Deppmann.

“OK, Show Me the Boiler and I’ll Help you out.”

A few months ago, I was at lunch with a commercial mechanical contractor. By the way, it was a real lunch, not a Zoom meeting. The contractor started asking about the importance of the R. L. Deppmann seminar series for the winter season. He told me the story. Last fall he purchased some equipment for a project from a competitor. The equipment was installed and ran fine for a short time. In the spring he received a call from the owner. There were complaints of sporadic shutdowns of the boiler. The younger salesperson who took the original order was called out to the jobsite to assist in troubleshooting.

The rep stood in the mechanical room and asked the contractor to take him to the equipment with the trouble. The response was, “it’s right behind you.” Imagine the look on the contractor’s face. The young salesperson was embarrassed and the customer lost confidence. No one wants this to be a story in their company.

Starting in the Industry

Employees are valuable assets of any successful company. Today, it appears there are more positions available than people to fill them. The result is a younger work force that is changing jobs and careers. The person you are hiring may have little knowledge of the industry and certainly little knowledge of your company.

Exposing this new employee to knowledge about the company, the job, and the growth opportunities is paramount. The new employee will leave you or you may leave them if they are not successful in a short time. There is a roadmap to training if you are willing to invest in it.

The New Employee Education Road Map

Image Credit: Carbuyer

Our company, R. L. Deppmann, is a successful manufacturer’s representative of hydronic, steam, and plumbing products in Michigan and Ohio. Our customers call us to help them solve problems because we have, and teach, the knowledge they need. How does this happen? Our hiring pool on the sales and engineering end is no different than other companies, but the training program is.

- Start with core values and what the company is all about. Our new employees are purposely exposed to the company business and culture three times in the first few weeks of their career. The HR department presents, the managing supervisor presents, and a senior manager describes the business and culture.

- Know the team that supports you. Our customers are contractors, wholesalers, and owners. It is important for the new inside or outside salesperson to understand the various departments of support.

- The new sales rep spends a short time in the warehouse, learning, seeing, and touching the products. They also begin to learn the ERP and CRM systems.

- Next, they move into the startup and warranty (service) department. Here they begin to see installed products and how they are commissioned. With the Service Tech as their mentor, the employee will gather knowledge of the terms used in the industry, proper installation, and troubleshooting. There is also a chance to interface with customers.

- Customer service/inside sales is the next stop. Here they begin the process of satisfying customer requests. They learn product, parts, and our business systems. They work in a team with open conversation about the hundreds of different product types and customer issues. The employee learns to help the customer make a better decision about what they are asking for.

- We have a strong new construction business. The salesperson will learn the plans, specifications, proper selection and sizing, proper detailing to avoid issues, and pricing. Here there is the baseline process of speaking with contractors, wholesalers, engineers, and coordinating with other employees.

- By this time, the employee is well into their training period. They now go out on calls with a senior sales rep. They are prepared with some understanding of product, installation, troubleshooting, selection, and quoting. Daily discussions with the senior rep will fill in the features, benefit, and competitive landscape for company and individual success.

- Now the employee is prepared to be a resource for their customer. They understand who knows what and the resources available to satisfy the customer’s needs. The new employee feels like they are part of a team. They may have developed a friendship with other employees. They feel like they belong.

Getting Started: How to Create a Training Program

This program may seem difficult to start. We developed this over many years. The departments a new employee is exposed to changes with their job. An accounting employee will go through the core ideology training. They may not experience the customer service department but warehouse experience in return goods or the purchasing process knowledge may help them do their job better.

Start with that core ideology process. Make sure the employee understands who you are, where you fit in the industry, and what to think about when making decisions. Next, just pick one support department for the job and list what they need to know about it. Communicate with all the department employees what the goal is and just try it out for a couple weeks. You will develop your own program.

Next quarter I’ll share the continuing training program we use once the employee is in the job full time.

Norman Hall is an engineer and leader at the R. L. Deppmann Company, a manufacturer’s representative, in Michigan and Ohio. Norm has assisted in the design and troubleshooting of hydronic and steam systems for 45 years.

Norman Hall is an engineer and leader at the R. L. Deppmann Company, a manufacturer’s representative, in Michigan and Ohio. Norm has assisted in the design and troubleshooting of hydronic and steam systems for 45 years.

It doesn’t seem so long ago we were fending off the “green” movement that was being force-fed into the vocab of working contractors. From green building to green technology, greenwashing was so prevalent that really the only “green” contractors were concerned with was the one they were chasing every day—a profit. But alas, a new Read more

It doesn’t seem so long ago we were fending off the “green” movement that was being force-fed into the vocab of working contractors. From green building to green technology, greenwashing was so prevalent that really the only “green” contractors were concerned with was the one they were chasing every day—a profit.

But alas, a new word has dominated the marketing lexicon—“smart.” Smart cars, smart phones, smart homes and yes, even smart pumps. “The problem is they’re not that smart,” says John Barba, contractor training manager, Taco Comfort Systems. “I’ve heard people who you’d think would know better say idiotic stuff like ‘these pumps do the thinking for you,’ and ‘they take the thinking out of it,’” says Barba.

Image Credit: Noven; Bethesda.net

How about giving credit to the users who actually interact with such devices? “The thing that separates the professional from the DIY’er or the handyman is his or her ability to think and their understanding of systems. That’s why people hire professionals, and that’s why our profession is so valuable. When it comes to systems and components, the professional is the smart one,” says Barba

“The professional knows what he’s holding in his hands, why he’s using it and what impact it’s going to have on the overall system performance. There’s not a pump made that can replace what the pro knows. The machines haven’t taken over yet,” continues Barba.

Intelligent Systems

If the integration or connectivity of disparate components to a holistic, communicative system is considered smart, then I’m buying in. Why not just say that in the first place? Because it’s not market-y, and it’s too long for a tagline. Okay, then the evolution of homebuilding can be categorized as being smart or intelligent because the integration of, say, lighting, security, home entertainment, etc., can be accessed from the convenience of your smart phone (more on that later). But I’d say that is more a matter or convenience than smarts.

In fact, as part of these communicative devices, perhaps on a broader, commercial stage, we are witnessing new phrases popping up such as the Internet of Things (IoT). According to Sokwoo Rhee, former associate director of the Cyber-Physical Systems Program at the National Institute of Standards and Technology (NIST) from 2014 to 2021, IoT can be described as the advancements in sensors and communication technologies that enable us to collect data which was not previously practical; the explosive increase of the amount of collected data enabled us to perform analytics which was not previously practical or meaningful; and the advancements in data analytics that will enable us to better control and optimize the systems to benefit our daily life. Again, I can buy into that.

Remember when cell phones were labeled smart phones? I think they still are. It’s 2007 and my fancy handheld device can make calls and perform functions as a computer. Well guess what? Today, they are just considered phones. And, if they don’t perform almost any function you can think of, well, then perhaps they are just dumb.

And, oh yeah, what makes a smart car? Good gas mileage? Actually, the term Smart Car came from a venture between watchmaker Swatch and Mercedes-Benz, with Smart standing for Swatch Mercedes Art, a branding stroke of genius. Its small stature was designed for city driving with big gas savings and easy maneuverability, with not-so-good safety ratings, I’d imagine. Debuting in the U.S. in 2008, last I read, it was discontinued in 2019.

And back to those smart, magical pumps? “The only word I hate more than ‘smart’ is ‘magic,’” says Barba. “Anyone who says something like that really doesn’t know how ECM circulators really work, or how they interact with systems. No matter how ‘smart’ people claim these things are, you can’t get away from the fundamentals of circulators. These things have performance—or ‘control’ curves—and the system still has a system curve,” says Barba.

According to Barba, there’s no such thing as magic, and the only circulator that can even come remotely close to sizing itself is the Taco VT2218—it’s a Delta-T circulator and varies its speed to maintain a fixed delta-T in the system.

“And I don’t care how many lights and buttons you put on the circulator, you can’t change the fact that when you have a fixed performance curve—as every Delta-P variable speed circulator has—the system has to work where the system curve intersects the control curve. If it’s a zone valve system, speed and flow will change as zone valves open and close, but it still works on the selected control curve. If it’s a zone pump system, a Delta-P circulator won’t vary its speed because there’s nothing in a zone that would create a change in pressure differential. It goes one speed and that’s it. That’s not what I’d call smart.

“Now, that doesn’t mean you shouldn’t use a Delta-P pump as a zone pump. You should—it’ll do some pretty cool things for you provided it’s set up properly. And for that, you need a smart installer who understands what these circulators do, what they don’t do and how they interact with the system,” says Barba.

“Just because a circulator is variable speed, that doesn’t make it magic. This isn’t Hogwarts and you’re not Harry-freaking-Potter.”

What’s my point in all of this? Dig deeper, educate yourself, rely on your experience and knowledge, and don’t rely on marketing taglines such as Smart or Green to sell you completely on something.