Viega Works online training also will continue. Broomfield, Colo. — Viega LLC will reopen its seminar centers in Colorado and New Hampshire on Aug. 1. The centers had been closed since March 2020 due to COVID-19. Viega is reopening them with new safety measures in place, including limiting class size, cleaning stations and mask requirements Read more

PVF

Viega Works online training also will continue.

Broomfield, Colo. — Viega LLC will reopen its seminar centers in Colorado and New Hampshire on Aug. 1.

The centers had been closed since March 2020 due to COVID-19. Viega is reopening them with new safety measures in place, including limiting class size, cleaning stations and mask requirements when appropriate.

“We’re excited to reopen and welcome back our customers, contractors and distributors,” said Jason McKinnon, director oftechnical services. “We moved training online during the pandemic and that’s been successful, but it’s going to be great to work in-person again with people.”

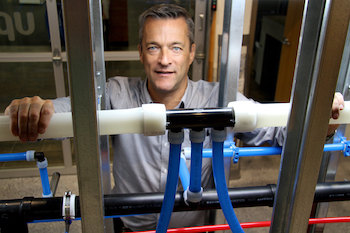

The seminar centers are located at Viega LLC headquarters in Broomfield, Colo., and in Nashua, N.H. Each features classrooms, hand-on workshops and interactive learning displays. Viega offers courses in a variety of subjects, including pressing, design and installation, and each course is customizable to meet the needs of our customers.

In response to customer demand during the lockdown, the company created Viega Works, online sessions largely limited to single companies. These programs, which can be as short as 30 minutes, are custom designed to cover the topics customers request.

“Customers like Viega Works because it’s fast and affordable and gives them the exact information they need without requiring travel or a major time commitment,” McKinnon said. “With the reopening of our seminar centers we offer even more opportunities to engage with our technical consultants than ever before. Customers can attend in-person at one of our seminar centers or contact us to set up a unique virtual experience with content specific to their team. No matter where or how you want to connect with our experts, we will make it easy and valuable for you and your organization.”

When I asked Sean Debnath, VP of Sales and Marketing, Viega, about the short-term economy earlier this year, he said, “The uptick in business that we all experienced gradually through Q3 and Q4 of 2020, seems to be continuing in to Q1 2021. But we choose not to take that trend for granted with all Read more

When I asked Sean Debnath, VP of Sales and Marketing, Viega, about the short-term economy earlier this year, he said, “The uptick in business that we all experienced gradually through Q3 and Q4 of 2020, seems to be continuing in to Q1 2021. But we choose not to take that trend for granted with all that is happening around us, and deal with it a month and a quarter at a time. Viega has taken steps with frequent testing and tracing to ensure we keep our factories and distribution centers running.”

Through all of this uncertainty and one month-at-a-time mentality, making the transition to a new CEO can be difficult enough. But through a pandemic? Mechanical Hub recently talked with Viega’s new CEO, Markus Brettschneider, about his vision for the company, and navigating through these uncertain times.

Through all of this uncertainty and one month-at-a-time mentality, making the transition to a new CEO can be difficult enough. But through a pandemic? Mechanical Hub recently talked with Viega’s new CEO, Markus Brettschneider, about his vision for the company, and navigating through these uncertain times.

MH: How has Viega navigated through the pandemic and what does the path moving forward look like as we start to normalize?

Brettschneider: Since the beginning of the pandemic, the health and safety of our people has come first. We put into place regular testing and safety measures at the facilities where in-person work was required. Moving forward, health and safety will continue to be our focus. Our other big focus is our customers, and we have done all we can to keep production and distribution as normal as possible. With all of the challenges in the logistical side, it’s a tense period. But we haven’t shied away from spending money to keep things running smoothly. We hope in the coming months to get colleagues back to the office and find new ways of working in various setups. We very much look forward to meeting our customers once again face-to-face, while at the same time being very careful and keeping everyone safe. So far this year, the outlook is positive.

Viega’s interactive displays in Broomfield, Colo.

MH: Has the company learned anything during the pandemic that will be implemented more into the business plan (virtual trainings, less travel, etc.)

Brettschneider: I think we have learned that virtually, a lot is possible. There are even certain benefits when it comes to training as well as new ways of engaging with customers. It will be interesting to see how things like trade shows and other events evolve in the future, but in 2020 we reallocated most of those funds into other channels to make the most of what we could. We didn’t cut any funding. Instead, we trained our own people to be capable in this digital environment, and have excelled with virtual education and customer events. We know there have been changes in buying behavior in the past year, and we remain open to this ever-changing business landscape.

MH: What are some of your top initiatives for the company?

Brettschneider: Our biggest priorities right now are safety and supply to the customers. We’re looking at things like raw materials, logistics and the availability of workforce. We are continuously investing in our company footprint through automation, digitization and robotization. This is all important to help drive growth with our customers. We also know how important it is to invest in virtual and online marketing, as well as launch additional customer training activities.

Viega’s Seminar Center in Broomfield, Colo., comes with a view.

MH: What has impressed you the most since joining the company?

Brettschneider: The people—our colleagues, the customers and the Viega family ownership. I’m extremely impressed with the products as well as the relationship we have with our customers and the opportunity to grow in our space. I’m also impressed with the commitment of the Viegener family to the company globally as well as its strong commitment to Viega LLC (the North American market) specifically. I’ve found the company is willing to constantly invest in order to grow the business, and the ownership’s passion and commitment is impressive.

MH: Explain Viega’s commitment to the supply chain and wholesale channels.

Brettschneider: We have proven our commitment to the supply chain, especially over the last few years . During that time, we grew the manufacturing and distribution presence in McPherson, Kansas, and we invested heavily in the workforce within the supply chain. We hired additional people to ensure our commitment in the U.S. is as strong as it always has been, and will continue. It’s important for us to invest for continual growth, and we know that our distribution and logistical centers are a key part of the business.

Training is paramount with Viega, and getting contractors back into the facilities, safely, is the goal.

A good example of our commitment was after the record cold snap in Texas and other southern states. We prioritized shipments and looked at unique ways to get products to the area that was so desperately in need of help. We are eager to work with our partners to drive growth, and are currently adding points of distribution throughout the U.S. We are a strong believer in wholesaler business and remain absolutely committed to our wholesaler distribution setup.

MH: What are some things you’ve learned throughout your career that will help you in your new position?

Brettschneider: Simply put, there is nothing more important than your own people and building great relationships with customers. Those ideas are central to a successful business.

MH: How do you see the short-term economy?

Brettschneider: Between the Covid relief package, some of the American population having more disposable income than ever, lower fixed-interest rates and potential infrastructure packages, we’re optimistic. We’ll see bumps here and there, I’m sure, because of the uncertainty of a global pandemic, but the fast-pace rollout of the Covid vaccination is giving us all a more positive outlook for the short-term U.S. economy.

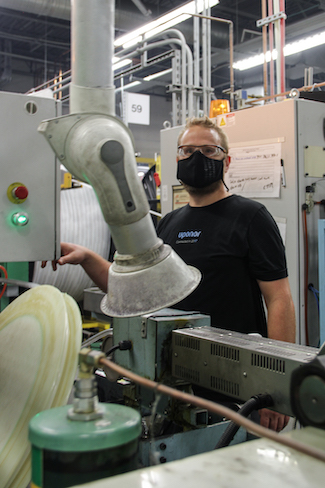

A McPherson, Kansas, facility.

MH: Provide an update of the McPherson locations — expansions, new innovations, etc.

Brettschneider: We have invested heavily in that location over the past few years, in both infrastructure and people. This year we are focused mostly on hiring people. It’s important to recognize we are investing not to just maintain, but to grow. Our plan has been to build for significant growth so that we are ready when there are sudden spikes in demand (such as the Texas cold snap). In terms of infrastructure, the expansion in logistics was completed early in 2020 and is fully operational. The new ProPress building is completed, with some machines in operation, while others will be arriving later this year (delayed due to Covid).

Mechanical Hub continues its series of exclusive Q & A sessions with industry leaders and players to get their views on the future, and living in a COVID world, and an insight into the market in 2021. The American Supply Association released its annual sales report for 2020 and the ASA Pulse sales report shows Read more

Mechanical Hub continues its series of exclusive Q & A sessions with industry leaders and players to get their views on the future, and living in a COVID world, and an insight into the market in 2021.

The American Supply Association released its annual sales report for 2020 and the ASA Pulse sales report shows member distributor respondents enjoyed an average sales growth of 4.4% and a median growth of 6% during the fourth quarter of 2020; however, distributor respondents doing business primarily in the industrial pipe, valves and fittings channel continued to report declines.

Total ASA distributor respondents reported a median 1.4% sales growth for the full year 2020 vs. 2019, and inventory levels rose 4.9% in the fourth quarter of 2020 compared to the fourth quarter of 2019.

Bill Gray

This week, Mechanical Hub features Bill Gray, president, Uponor North America to get his company’s pulse for 2021. You get the sense that it’s time to move forward and the time is now to take full advantages of the opportunities that lie ahead.

MH: While putting together the Mechanical Hub annual forecast last year, you were one of the only ones to go on record who took COVID into account in the short-term up until that point in mid-January 2020. What were you hearing?

GRAY: We were starting to hear “noise” in the supply chains. You have to understand, I have a mother in the background who was reading all the articles, warning me about traveling to Europe and Hawaii. What sounds like wisdom from me is actually deriving from my mother yelling in the background to stay home.

MH: Most of the residential guys are doing fine, but there are hiccups with commercial and industrial sectors. What does the short-term economy look like for Uponor? What are the economic indicators telling you?

GRAY: This is a question we try to answer on a weekly or bi-weekly basis with our European parent company. We are currently enjoying a very healthy level of business. In 2020, we hit the brakes in April after a great first quarter. By the end of May, it was all back in a big way. All that demand that fell off, people decided to get that work done. Through Q3, it was good volume.

We knew there was more volume going into residential. For commercial, no one was stopping projects already coming out of the ground. I don’t know when we will see commercial projects begin to tail off. As you know, 12, 18, or 24 months is nothing to get a commercial project rolling. What I am told is that there are fewer projects to quote in commercial order books. Certain segments are more adversely impacted than others. For example, it is hard to imagine you are going to build a new hotel if you haven’t already broken ground.

I am one of those guys who normally spends 75 to 100 nights a year in a hotel. In 2020, I spent maybe 20, and all of those were at the beginning of the year. So that challenge to commercial will keep getting pushed forward. They will still need to perform retrofits, and that might open up some opportunities.

Residential is on fire, supported by demographic demand that has been held back. We often speak of “natural” household formations coming in at 1.5 million annually. We never achieved that level coming out of the past recession, so the demand gets pushed forward. Meanwhile, existing homes valued between $250,000 and $500,000 are going for the asking price or higher and don’t last very long at all on the market. Builders of new homes are building into their 2022 and 2023 land plans currently.

One of the factors that may bring down that activity is that builders cannot get land fast enough, as they burn up all of their lots now. So, we are in a window now, and everyone is building homes as fast as they can, and prices are slowly climbing. Input prices are crazy. Truss packages—nobody builds trusses on the job site anymore—are going for 3X or 4X vs. 2020 levels. Insulation deliveries are crazy; all the HVAC and mechanical stuff—crazy. Our friends over at Bradford White are at six to eight weeks currently.

There is demand out there. RWC just released their numbers, but had great sales growth last year with more exposure to DIY through Home Depot and Lowe’s. We know the latter pair are doing very well. We are seeing a lot of switch-in-spend right now. “I cannot go on vacation, so I am going to work on my house and yard.” Many cannot get a contractor to do the work, and if they do, the pricing can be very high. “I’m willing to take the work, but it will cost you.”

MH: As far as inventories and supply, how is Uponor faring?

GRAY: We shut down the plant for eight days in April and laid off some staff in distribution and manufacturing. We have them back, plus. We are up to a month behind right now against a strong order volume. We were famous for delivering our product on time and in full. The problem definitely relates more to residential—smaller-diameter pipe.

It is what it is right now, but I question how long this activity can be sustained. Most companies, from what I have read, are saying like the first half, maybe through Q3 2021. But there is no election this year. We will see what happens with the stimulus packages. Do they finally do something on infrastructure? We need infrastructure work—now is the time to do those projects. Money will never be cheaper, nor labor more plentiful. But if you wait until a full economy, the challenges will be much greater.

I think if the federal government plays this right, understanding the dynamics of the market today—like in 2008-09, shovel-ready projects that will keep the economy going—I think construction could be really good—or really challenging. A lot of variables have not played out yet.

MH: How are you steering the ship to deal with COVID? You have gotten through 2020, is it all systems go? Anything different?

GRAY: What we did as well as or better than anyone else—not just in our industry, but in other industries too—is that we got on top of the problem early with our COVID Task Force. Originally, we were focused on problems in the supply chain, but that transitioned very quickly to our employees’ health and safety, as COVID hit the United States. We started looking at where our employees were traveling for work, creating an awareness, telling them if you are going to an area that may be compromised, be sure you are taking the proper precautions for yourself and your colleagues.

We were able to keep the plants open, because we were designated—along with most of new-construction markets and building products—as essential services. We have been promoting health and safety first, then the continuity and integrity of our factories, making sure we are able to ship products to customers. That is how we cascaded these priorities.

At Uponor, we went virtual on Friday, March 13, 2020, with the idea that we should test our systems in case we must work from home at some point, and everything worked out well from an IT perspective. As it turned out, ironically, the mandate to work from home came down over that weekend.

Next, we did a live migration to Microsoft Teams, which was a huge improvement over our previous platform.

As the situation has “stabilized” now—as much as it can be stabilized—we are continuing monthly calls with all employees. The leadership team and I continually explore what’s new, what’s different? When can we expect to come back to the office? What’s coming back going to look like? We try to manage all that.

From my perspective, we won’t be coming back to anything normal probably until 2022. My boss from Finland visited the United States the week before the AHR Expo in 2020. I don’t expect to see him in the United States at all in 2021. It’s been spotty in that part of the world, although with their stronger central governments, they seem to have managed COVID more effectively. Their countries haven’t had the same levels of infection. My next trip to Europe may be Q1 of 2022. By then, I should have the vaccine, I am confident.

The big unknowns on the horizon are the variants of COVID and whether the vaccines will help prevent their spread. Or is our future more pandemics? I don’t know right now.

MH: Last month, Uponor launched its new Complete Polymer Solution for commercial-piping applications in the U.S. How do you manage a launch like this in the midst of a pandemic and the cancellation of a major trade show?

GRAY: We did a soft launch around the announcement of the relationship with Pestan at the AHR Expo in 2020. We understood the amount of work that lay in front of us. For a company like Uponor to launch a product line of this magnitude, it is a major endeavor.

Which is why I have such an appreciation for our team and their ability to pivot at every opportunity, figuring out just how we would get all the work done. We knew the objective; we knew the amount of work we had to do. But there was a tremendous amount of creativity to making it all happen. Working with our health and safety people, our team developed a protocol for how we would do all this work internally while maintaining proper social distancing.

Then, with the launch itself, there is a lot to going virtual. It may look like it’s going rather smoothly. But when you see the machine behind the people, and how it makes this all work, you can’t help but be impressed. I did my on-camera interview a couple of weeks ago, and at the time it feels like a disparate collection of takes and cuts. But they brought it all together through an editing process that makes even me look good. That’s a pretty tall order!

MH: The market for this PP-RCT launch right now: Is it targeted for domestic water as well?

GRAY: We believe the best opportunity is mechanical. Pursuing domestic water would fragment our efforts. If we focus on mechanical and get really good at that, we can start taking on plumbing. Plumbing is more complex than mechanical; there are different dynamics at play. We think this is the best strategy for us right now. If you are a small company without much of a brand, you can do a lot more across more markets without much risk. If Uponor puts its name on something, we want to make sure we have it right, so our customers are confident it will work.

That is part of the leverage we are providing. If Uponor is offering these products with the full bundle of support—the national rep network, our knowledgeable sales force, on-site training and technical support—the customer can feel better about getting involved. We just felt plumbing would fragment our efforts too much.

Bill Gray is president, Uponor North America.

Bill Gray is president, Uponor North America.

Elkhart, Ind. — NIBCO INC. announced that its Board of Directors appointed Ashley Martin as executive vice president effective immediately. Reporting to Steve Malm, president and CEO, Martin continues in her role as corporate officer and Executive Leadership Team member; and serves as member of the Board of Directors, a position she has held since Read more

Elkhart, Ind. — NIBCO INC. announced that its Board of Directors appointed Ashley Martin as executive vice president effective immediately. Reporting to Steve Malm, president and CEO, Martin continues in her role as corporate officer and Executive Leadership Team member; and serves as member of the Board of Directors, a position she has held since 2018. She is responsible for maximizing the company’s operating performance and achieving its financial goals.

Elkhart, Ind. — NIBCO INC. announced that its Board of Directors appointed Ashley Martin as executive vice president effective immediately. Reporting to Steve Malm, president and CEO, Martin continues in her role as corporate officer and Executive Leadership Team member; and serves as member of the Board of Directors, a position she has held since 2018. She is responsible for maximizing the company’s operating performance and achieving its financial goals.

“Ashley’s business acumen, industry connections and experience have prepared her well,” said Steve Malm in announcing Martin’s appointment. “Her innate leadership qualities and strategic vision will successfully propel NIBCO forward into its fifth generation.”

Since joining NIBCO in 2012, Martin has held a variety of positions including senior vice president, sales; vice president of wholesale sales; general manager of PEX; and director of distribution and transportation.

Martin co-founded the American Supply Association Women in Industry group in 2013. She served a two-year term as chairperson, beginning in 2016.

Martin received her bachelor’s degree in marketing from the University of Notre Dame in Notre Dame, Ind. She holds a master’s degree in business administration with a concentration in strategy and operations management from Southern Methodist University in Dallas, Texas.

When you take an old space and make it new, there are inherent challenges to it. And that’s exactly what happened with a restoration project in downtown Buda, Texas. Tight spaces to work in meant Viega products were a perfect partner. In the downtown space, old and unused factories have slowly been getting facelifts. Developers Read more

When you take an old space and make it new, there are inherent challenges to it. And that’s exactly what happened with a restoration project in downtown Buda, Texas. Tight spaces to work in meant Viega products were a perfect partner.

In the downtown space, old and unused factories have slowly been getting facelifts. Developers are turning them into retail and restaurant spaces. It’s what Hill Country Plumbing was brought in to do with the old Buda Mill and Grain Company, changing it into Los Olivos Market, a wine shop and bistro.

“The big challenge was that there was another restaurant backing up to it, a common space with a delineating wall,” explained Colie Curry, owner of Hill Country Plumbing. “And there were two different architecture firms that got their measurements inconsistent, so we had to sacrifice space. The roof space we had for grease vents and mechanicals was very tight.”

“The big challenge was that there was another restaurant backing up to it, a common space with a delineating wall,” explained Colie Curry, owner of Hill Country Plumbing. “And there were two different architecture firms that got their measurements inconsistent, so we had to sacrifice space. The roof space we had for grease vents and mechanicals was very tight.”

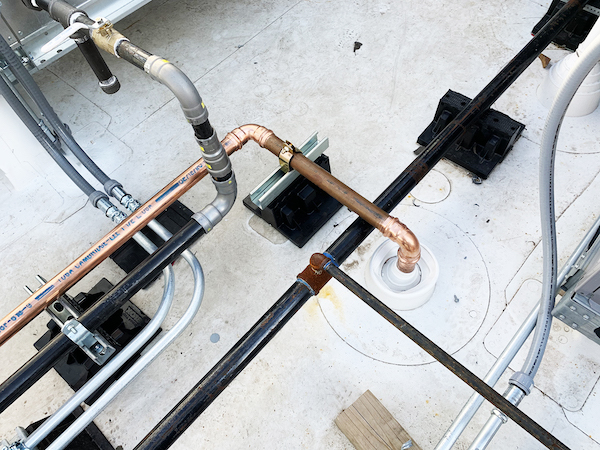

Existing utilities had been run through the ceilings and were undersized for the new needs, so everything had to be retrofit. The 2½” gas line ended up going up the exterior of the building, down a soffit and then jumping up onto a flat roof to bypass a walkway access—in other words, it would have been nearly impossible to thread pipe together where it needed to be hung.

“I’ve been a fan of Viega for years and we use PureFlow on a daily basis—plus I’ve used smaller MegaPressG fittings,” Curry said. “I heard that the larger diameter was coming out in January, and we did this project in March, so the timing was perfect!”

With the help of Viega reps, Curry acquired a MegaPress PressBooster and rings so he could get the project done on time. There were about 20 fittings in the 2½” size, and then the pipe necked down to 2” for the equipment manifold and again to ¾”.

“We could have tried to thread, but hanging a 50-foot-long piece of threaded pipe that is 2½” and weighs 300 pounds would have taken six guys – that’s not good. Plus, we would have had to work our way from it after hanging it,” Curry said. “With Viega, we were able to work in multiple directions. We did a lot of the interior piping before the roof penetration, and we could cut in wherever we needed.

“In about four and a half hours we did what would have probably taken two days—it was a ton of labor savings! And if there had been a leak we would have had to start over after cutting that part out. Using the Viega fittings worked out really, really well.”

“In about four and a half hours we did what would have probably taken two days—it was a ton of labor savings! And if there had been a leak we would have had to start over after cutting that part out. Using the Viega fittings worked out really, really well.”

Curry and his crew also used PureFlow PEX, in sizes 1¼” and smaller, for waterlines to the bathrooms and commercial kitchen.