Hydronic systems outperform VRF, study finds In a study commissioned by Xylem Inc. that evaluated HVAC systems in a number of South Carolina school buildings, hydronic systems outperformed all other systems, including VRF, in terms of lower energy use, cost and life expectancy, by as much as 24%. “With HVAC systems dictating a substantial amount Read more

Radiant heating

Hydronic systems outperform VRF, study finds

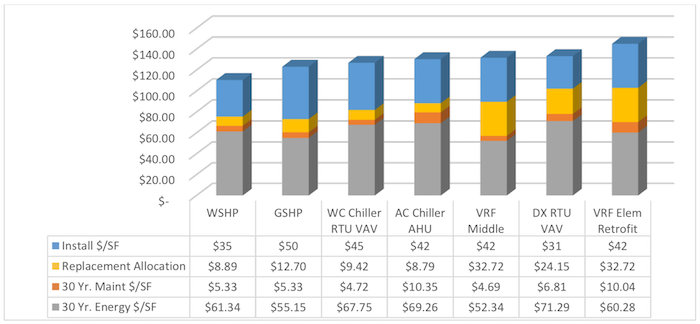

In a study commissioned by Xylem Inc. that evaluated HVAC systems in a number of South Carolina school buildings, hydronic systems outperformed all other systems, including VRF, in terms of lower energy use, cost and life expectancy, by as much as 24%.

“With HVAC systems dictating a substantial amount of the overall energy use of commercial buildings, the results shed light on the importance of evaluating varying system-to-system costs before installation,” said Kyle DelPiano, Business Development Director, CBS Market, Xylem. “More than ever, energy-efficient practices are driving the construction industry toward more sustainable solutions, and this study proves long-term cost savings that can’t be overlooked when making the choice between hydronic and VRF systems.”

To compare and contrast HVAC systems according to their 30-year life-cycle cost analysis (LCCA), the Xylem study analyzed seven elementary and middle schools located in South Carolina Climate Zone 3A, a humid, warm climate. The cost analysis included upfront installed cost, replacement cost allocations and ongoing energy and maintenance cost of the following system types:

- Variable refrigerant flow heat pumps (VRF)

- Water source heat pumps (WSHP)

- Ground source heat pumps (GSHP)

- Direct expansion rooftop units (DX RTU)

- Water cooled chillers (WCC)

- Air-Cooled Chillers (ACC)

The findings of the study revealed that the schools with WSHP, GSHP and WCC systems displayed energy use levels that were 30%, 41% and 25% better than the national median for elementary and middle schools, respectively. The replacement cost allocation also acknowledged that the tested hydronic systems operate effectively for approximately 25 years, as opposed to the 15-year replacement estimation for VRF systems.

The tested VRF systems required replacement a decade earlier because of their tendency to work harder during heating cycles, bringing proof of long-term cost savings to the forefront of the conversation surrounding sustainability and hydronic HVAC system efficiency.

Replacement allocations had an impact on the life-cycle cost analysis (see yellow bars) and drastically reduced the cost effectiveness of equipment with 15-year life expectancies.

Considerable benefits of the hydronic HVAC systems included lower energy usage intensity and cost, wider range of maintenance flexibility and longer life expectancy.

The full research study can be found here: https://bit.ly/35AtpXb. For more information about Xylem, visit www.xylem.com.

tekmar Control Systems has announced the addition of four new switching relay and zone valve control models to their existing line of zone control solutions. tekmar now offers 2-zone pumps, 3-zone pumps, 3-zone valves, and 5-zone valves. The newly added switching relays and zone valve controls are compatible with all low-voltage thermostats and offer a Read more

tekmar Control Systems has announced the addition of four new switching relay and zone valve control models to their existing line of zone control solutions.

tekmar now offers 2-zone pumps, 3-zone pumps, 3-zone valves, and 5-zone valves. The newly added switching relays and zone valve controls are compatible with all low-voltage thermostats and offer a variety of benefits for homeowners. These include unlimited expansion; exercising, which prevents pumps from seizing during the summer; zone priority; and priority override to protect homes from freezing over the winter months.

The switching relays and zone valve controls also send out a RoomResponse™ signal to automatically adjust boiler temperatures to improve comfort, conserve energy and save money.

Learn more about switching relays and zone valve controls by tekmar and see the complete lineup of 1-6 zone pumps and 3-6 zone valves at www.tekmarcontrols.com/products/zoning.html.

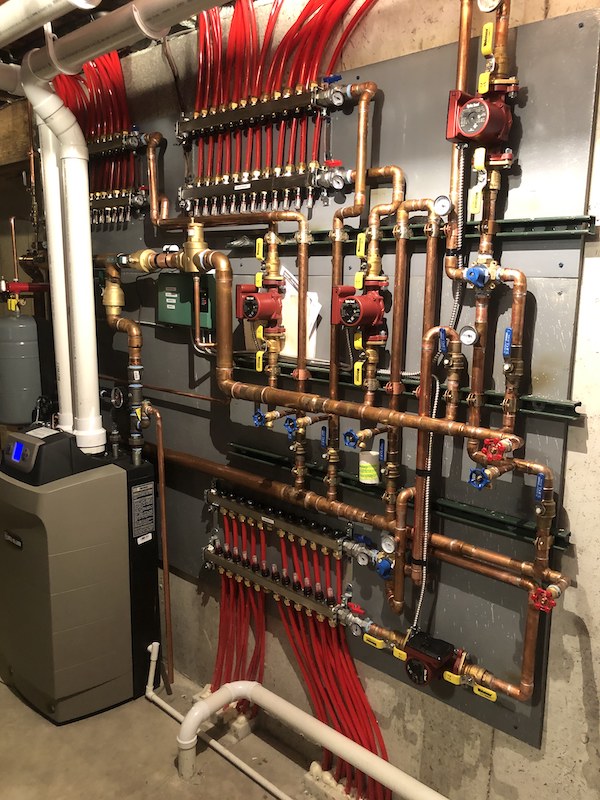

When you take pride in your work, the craftsmanship shines through, and the customer receives a reliable, comfortable radiant heating system. Tim Kuhlman, plumbing tech, Grasser’s Plumbing & Heating Inc., McNabb, Ill., is no stranger to meticulous installs and a job well done. Grasser’s is a family-owned plumbing and HVAC company serving the Illinois valley for Read more

When you take pride in your work, the craftsmanship shines through, and the customer receives a reliable, comfortable radiant heating system. Tim Kuhlman, plumbing tech, Grasser’s Plumbing & Heating Inc., McNabb, Ill., is no stranger to meticulous installs and a job well done. Grasser’s is a family-owned plumbing and HVAC company serving the Illinois valley for more than 60 years.

To put it directly, the Oglesby, Ill. customer at a larger residence—3,186-sq.-ft. main floor; 3,300-sq.-ft. basement; and 1,200-sq.-ft. garage—wanted a professional install that worked. As a result, “The customer is very happy with the boiler install and performance of the system,” says Kuhlman.

As part of the solution, Kuhlman used tekmar 4-way mixing valves to raise the return temps for the garage and basement — the main floor set point is 140 degrees F; the basement and garage set points are 120 degrees F. The garage is set to 58 degrees F, the basement at 65 degrees F and the main floor to 68 degrees F.

As part of the solution, Kuhlman used tekmar 4-way mixing valves to raise the return temps for the garage and basement — the main floor set point is 140 degrees F; the basement and garage set points are 120 degrees F. The garage is set to 58 degrees F, the basement at 65 degrees F and the main floor to 68 degrees F.

Inside the Mechanical Room

• Boiler — Weil McLain/ultra 230 series 3

• Water heater — Navien 240A (not shown)

• Pumps — Grundfos UPS15-58FC, 3 speed circulator Relays

• Zone controls — Taco 4 Zone pump relay

• Piping – All primary and secondary piping done in copper with sweat fittings • • Main Tools Used —Bernzomatic TS8000 torch,

• Valves — Webstone isolation pump valves

• Separators —2” spirotherm air seperatore, Flexconsole expansion tank holder

• Expansion tanks —#60 Extrol expansion tank

• Other—three 12-loop 1” stainless steel uponor radiant heat manifolds and one 4-loop uponor ep manifold for garage.

Spirotherm introduces Spirocombi Magnet for superior air elimination and protection of system components. Spirotherm, the leading manufacturer of coalescing-type air and dirt separators, introduces a new combination air and dirt separator that includes magnets and a universal connection. Building on the legacy of the reliable Spirovent air eliminator, the Spirocombi Magnet delivers the same air Read more

Spirotherm introduces Spirocombi Magnet for superior air elimination and protection of system components.

Spirotherm, the leading manufacturer of coalescing-type air and dirt separators, introduces a new combination air and dirt separator that includes magnets and a universal connection. Building on the legacy of the reliable Spirovent air eliminator, the Spirocombi Magnet delivers the same air separation efficiency and adds fast and effective separation of ferrous and non-ferrous debris.

Spirotherm, the leading manufacturer of coalescing-type air and dirt separators, introduces a new combination air and dirt separator that includes magnets and a universal connection. Building on the legacy of the reliable Spirovent air eliminator, the Spirocombi Magnet delivers the same air separation efficiency and adds fast and effective separation of ferrous and non-ferrous debris.

Powerful magnets located on the exterior of the housing surround the flow-path of the system water to efficiently capture ferrous material. By sliding the magnet jacket down, the collected debris can be flushed from the unit without having to isolate or open the unit.

The Spirocombi Magnet includes a rotating universal connection that allows installation in horizontal or vertical piping, accommodating both traditional and wall-mount boiler installations. Sizes 3⁄4”, 1”, 11⁄4”, 11⁄2” and 2” are available with threaded, sweat and press fit connections.

With a design that combines air elimination and dirt separation in a single unit, installation is simplified while protecting system equipment from corrosion and ferrous material. Constructed from quality materials, the Spirocombi Magnet is backed by a 20-year limited warranty.

For more info, http://www.spirotherm.com

For the past 11 years, my job as a technical trainer has taken me from Alaska to Cuba, with many stops in between—I have been to all 50 states. Transitioning from a hands-on plumber to a talking head, standing in the front of the room addressing thirsty-for-knowledge contractors, took some getting used to. No doubt Read more

For the past 11 years, my job as a technical trainer has taken me from Alaska to Cuba, with many stops in between—I have been to all 50 states. Transitioning from a hands-on plumber to a talking head, standing in the front of the room addressing thirsty-for-knowledge contractors, took some getting used to.

No doubt the travel part of a “traveling trainer” job is the most challenging. Hours spent squeezed inside an aluminum sausage, aka big, old jet-airliner, can be frustrating. I do love the views and amazing sunset and sunrises I have seen. Lightning show, massive clouds are incredible, but they never look the same on the phone camera. For the most part the airline folks have been helpful and accommodating.

When they see the miles you rack up as a business traveler, they will almost always accommodate your request. Approaching them without a chip on your shoulder helps the outcome. Maybe it’s me, but it seems like a lot more delays and cancelations lately, busy times in the air travel business. So, I usually plan for some shuffling and exercise some chill skills. But I digress.

Once at the location, the fun part begins for me. I enjoy sharing what I have learned and listening to stories from attendees. For sure, my favorite parts of the job are the shop and jobsite visits. I learn from seeing how the new products and technology are actually being blended together on actual jobs. Browsing through the back rooms of the wholesaler and rep buildings can provide some good intel.

Living the Rock Star life.

I try to balance my training between product pitch and theory, applications, tips and tricks. It is important that the training sponsors advertise and promote the training accurately. If the training is intended to be all product and sales, that needs to be clear, so the folks attending know what to expect. Technical guys and gals prefer technical topics, from my experience.

I try to engage the group as much as possible, learn their skill level and expected outcome. Training for me is a give and take experience, as nobody knows it all. Except perhaps my wife. (Shhhh!) Generally, the room is a mix of expertise levels, so try to include info for everyone to leave with. Know your audience!

Hot Rod preparing for a Coffee with Caleffi webinar.

The dynamics of a room vary depending on the group. If you have a roomful of competitors, the questions do not flow so easily. Training at shops, reps and wholesalers always result in more interaction.

During the lunch break, spring for some food for the group, even if it is good pizza. Shop for the local brand favorite.

I’ve found a 4-hour maximum for tech heavy topics is a good lid for an event. It’s tough to keep a blue-collar person down as they need to keep moving. Their backs and knees make sitting for a long time challenging, too.

I always want to leave the attendees with a nice hard copy of the material we covered. The Caleffi Idronics are perfect handouts: They are a reference, both as a hard copy and online version. Also, it’s always nice to see the group taking notes in the margins.

Back at the office—in-house—I help produce the Coffee with Caleffi series, a webinar that cover important topics in the plumbing and hydronics industry.

If we haven’t met or shared a gab session together, I hope to do so soon. I’ll keep in communication with the Mechanical Hub community about dates and times for upcoming seminars, and webinars!

Bob ‘Hot Rod’ Rohr is director of training and education at Caleffi.