For residential plumbers, there have been two schools of thought for plumbing a house: home run and trunk and branch. Both have their positives and negatives, depending on what you’re trying to accomplish with the plumbing system. However, you may not know there’s a new (and smarter) way to design and install a residential plumbing Read more

residential

For residential plumbers, there have been two schools of thought for plumbing a house: home run and trunk and branch. Both have their positives and negatives, depending on what you’re trying to accomplish with the plumbing system.

For residential plumbers, there have been two schools of thought for plumbing a house: home run and trunk and branch. Both have their positives and negatives, depending on what you’re trying to accomplish with the plumbing system.

However, you may not know there’s a new (and smarter) way to design and install a residential plumbing system that installs faster, uses less materials, requires fewer connections, minimizes your liability and operates more efficiently.

It’s called Logic plumbing.

A Logic plumbing design can only be used with PEX piping, but since PEX is now used in more new-home construction than copper and CPVC combined, you’re most likely already using it. (And if you’re not, you need to check it out. PEX is highly durable, flexible and more cost-effective compared to copper and CPVC.)

The Logic approach leverages the flexibility of PEX pipe to minimize connections and reduce potential leak points while also incorporating multiport tees located near fixture groupings to both limit the amount of pipe and connections needed while also improving installation efficiencies and system performance.

What’s a multiport tee?

I’m sure right now you’re wondering, “What’s a multiport tee?” It’s essentially a bunch of tees all molded together to create one long tee with multiple outlets. This innovative product minimizes connections and is the heart and soul of a Logic design.

For example, six regular tees will have 18 connections, but a flow-through multiport tee with six outlets will only have eight connections (six connections for the ports, a main flow-through inlet and a main flow-through outlet). Think about how much faster you could install a system when you’re making half the number of connections.

For example, six regular tees will have 18 connections, but a flow-through multiport tee with six outlets will only have eight connections (six connections for the ports, a main flow-through inlet and a main flow-through outlet). Think about how much faster you could install a system when you’re making half the number of connections.

And get this — while multiport tees may resemble a manifold, they have the benefit of being hidden behind walls without the need for an access panel. Yes, you heard that right. No need for an access panel, minimizing costs and labor to help keep your projects on schedule and on budget.

Multiport tees are made of engineered polymer (EP), a thermoplastic material that has been used in plumbing applications for more than 20 years. EP has superior mechanical, chemical and thermal properties that provide dimensional stability in demanding applications, including areas of high stress, heat and moisture.

And, like PEX, the EP material in multiport tees resists corrosion, pitting and scaling, so it creates a highly durable system that’s engineered to last. Best of all, multiport tees (as well as all EP fittings) are approved for direct burial in the soil or concrete slab, so they are ideal for in-slab plumbing applications.

The Logic layout

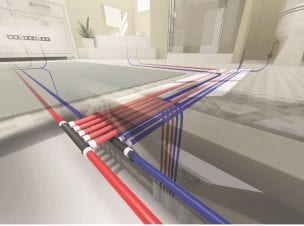

So what exactly is a Logic plumbing layout? It’s quite simple: a main line connects to a multiport tee with distribution lines going out from the tee. These individual lines extending from the single multiport tee provide water to all fixtures in a single or adjacent grouping.

This design uses significantly less pipe than a home-run layout, with just a few more connections. Plus, it requires considerably fewer connections compared to a trunk-and-branch installation.

This design uses significantly less pipe than a home-run layout, with just a few more connections. Plus, it requires considerably fewer connections compared to a trunk-and-branch installation.

For example, a 2,300-square-foot, two-story home using a Logic design requires only 637 feet of pipe while a home-run system uses 1,515 feet of pipe. That’s more than twice the amount of piping necessary.

In addition to the added costs required to install all that extra pipe, the system performance is also greatly reduced due to added pressure loss and longer wait times for hot water. Plus, all the extra pipe can lead to issues isolating hot and cold water lines. This increases heat transfer and energy inefficiencies within the plumbing system.

And, while it’s true a Logic installation uses slightly more connections than a home-run layout (59 vs. 48 in the 2,300-square-foot, two-story home example above), the amount of pipe savings is significantly more beneficial with the labor and material savings you get with less pipe to install (not to mention the efficiency of the system).

A Logic layout also installs much faster compared to a trunk-and-branch system due to the vast reduction in connections. With the two-story home example above, a Logic layout uses a mere 16 fittings and 59 connections compared to a whopping 96 fittings and 165 connections for trunk and branch. That’s six times the number of fittings and nearly three times the amount of connections!

All those added connections greatly increase your liability with more potential for leaks, plus it also limits the performance of the system with increased pressure loss.

So there you have it! Just a few “logical” reasons why you should consider a smarter approach to plumbing a home that will improve your installation times, limit your liability and offer an all-around better-performing system for the end user.

Kim Bliss is the content development manager at Uponor. She can be reached at kim.bliss@uponor.com.

The Grundfos UP10-16 HWR range sets a new standard for energy efficient hot water recirculation in residential homes. Thanks to a low noise permanent magnet motor, energy consumption is reduced to as little as 5-8.5 W. UP10-16 HWR pumps are simple to install and deliver reliable operation for applications with a foot print of up-to Read more

Grundfos UP10-16 HWR Auto

The Grundfos UP10-16 HWR range sets a new standard for energy efficient hot water recirculation in residential homes. Thanks to a low noise permanent magnet motor, energy consumption is reduced to as little as 5-8.5 W. UP10-16 HWR pumps are simple to install and deliver reliable operation for applications with a foot print of up-to 2,000 square ft.

Three different control modes make it easy for you to select the right pump for your application:

- Basic Control Mode: The pump runs at 100% mode constantly.

- Temperature Control Mode: Keeps the water temperature within an optimal temperature range that is calculated every 24 hours. Perfect for homes with multiple occupants and unpredictable hot water usage.

- Auto Control Mode: Learns the hot water consumption patterns of the homeowner and adapts operation time accordingly. Ideal for energy conscious households with regular hot water usage.

Key features and benefits:

- Can save up to 13,000 gallons per year by eliminating the wait for hot water

- Compact design makes installation simple, even in confined spaces

- Easy to use push button controls

- Lead free brass housing eliminates risk of corrosion

- 6-ft line cord standard

- Union housing integral stops

- Built-in non-return valve

- Built in check valve (union models)

Learn more about our full range of hot water recirculation pumps Grundfos offers, visit www.grundfos.us/up10

Lochinvar is enhancing its top-performing high-efficiency condensing residential KNIGHT Fire Tube Boiler series with 95 percent DOE AFUE and advanced control functionality for optimized heating comfort. Now in its fourth generation, the designed, engineered and assembled in the U.S.A. KNIGHT Fire Tube Boiler contains 13 models — seven wall-mount options (55,000 to 399,000 Btu/hr) and Read more

Lochinvar is enhancing its top-performing high-efficiency condensing residential KNIGHT Fire Tube Boiler series with 95 percent DOE AFUE and advanced control functionality for optimized heating comfort.

Lochinvar is enhancing its top-performing high-efficiency condensing residential KNIGHT Fire Tube Boiler series with 95 percent DOE AFUE and advanced control functionality for optimized heating comfort.

Now in its fourth generation, the designed, engineered and assembled in the U.S.A. KNIGHT Fire Tube Boiler contains 13 models — seven wall-mount options (55,000 to 399,000 Btu/hr) and six floor-standing models (55,000 to 285,000 Btu/hr) — with turndown ratios of up to 10:1.

“Lochinvar’s engineering team does not rest on the success of a great product, and the KNIGHT Fire Tube Boiler evolution is proof of our relentless push to improve performance for homeowners and make installation and set up a snap for contractors,” said Dan Rettig, residential product manager at Lochinvar. “Whether a contractor is installing for new construction or performing a drop-in replacement on an older boiler system, the KNIGHT series has the flexibility and muscle to meet the space-heating demands of nearly any residential application. This is without a doubt the best KNIGHT boiler yet.”

To achieve cost-efficient performance and rugged reliability for homeowners, the KNIGHT Fire Tube Boiler is manufactured with high-quality components, including a corrosion-resistant stainless steel fire-tube heat exchanger and a negative regulation combustion system. Additionally, each KNIGHT boiler will be packaged with a variable-speed ECM circulator, which can save up to 90 percent on operational costs over a conventional circulator.

Every KNIGHT Fire Tube Boiler comes equipped with SMART SYSTEM, the industry’s most advanced boiler control system, which now includes the CON·X·US Remote Connect option and the LOCH-N-LINK® USB Programming feature. The Set-Up Wizard guides contractors through installation programming while Lochinvar’s exclusive CON·X·US Remote Connect option allows a technician or homeowner to monitor and manage the boiler from a mobile app.

Lightweight with a compact footprint and easy-to-access components, the entire series is designed to make installation, setup and serviceability straightforward for contractors. For instance, the KNIGHT Fire Tube Boiler features:

- LOCH-N-LINK USB Programming with parameters uploaded from a thumb drive

- Universal vent adapter, which allows for easy transition to multiple types of vent material

- Variable-speed pump that increases system efficiency and reduces operational costs

- Dual location parameter memory for quick and simple component replacement

- Electrical outlet on the unit for a work light or condensate pump

- Wall- and floor-mount options with top and bottom water connections.

For larger residential applications, KNIGHT Fire Tube boilers can be cascaded together for redundancy and may also be paired with an indirect water heater.

The high-efficiency condensing gas KNIGHT Fire Tube Boiler series first launched in 2005. Since its introduction and through four generations, the KNIGHT Fire Tube boiler has established a reputation for reliable performance among contractors.

For more information about Lochinvar, visit www.Lochinvar.com.

Designed for sustainable underground or under-slab fluid transfer in a variety of hydronic heating, cooling and potable-water systems, Uponor Ecoflex® is an easy-to-install, dependable, energy-saving solution for any residential or commercial application. Available with service pipe from 1″ up to 4″ and insulation thicknesses up to 2″, Ecoflex can help comply with ASHRAE 90.1-2013 and Read more

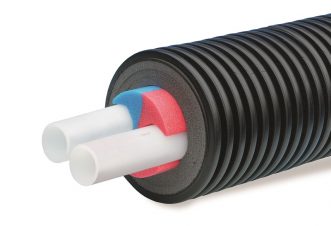

Designed for sustainable underground or under-slab fluid transfer in a variety of hydronic heating, cooling and potable-water systems, Uponor Ecoflex® is an easy-to-install, dependable, energy-saving solution for any residential or commercial application. Available with service pipe from 1″ up to 4″ and insulation thicknesses up to 2″, Ecoflex can help comply with ASHRAE 90.1-2013 and International Energy Conservation Code (IECC) requirements.

Designed for sustainable underground or under-slab fluid transfer in a variety of hydronic heating, cooling and potable-water systems, Uponor Ecoflex® is an easy-to-install, dependable, energy-saving solution for any residential or commercial application. Available with service pipe from 1″ up to 4″ and insulation thicknesses up to 2″, Ecoflex can help comply with ASHRAE 90.1-2013 and International Energy Conservation Code (IECC) requirements.

Visit uponorpro.com to learn more.

While PEX has been used for more than 40 years in radiant heating applications, it’s now getting more traction in commercial hydronic heating and cooling applications as well. Contractors and engineers are beginning to spec and install PEX for distribution piping to various terminal units, such as fan coils, reheat coils, heat pumps, baseboard radiators Read more

While PEX has been used for more than 40 years in radiant heating applications, it’s now getting more traction in commercial hydronic heating and cooling applications as well. Contractors and engineers are beginning to spec and install PEX for distribution piping to various terminal units, such as fan coils, reheat coils, heat pumps, baseboard radiators and chilled beams.

While PEX has been used for more than 40 years in radiant heating applications, it’s now getting more traction in commercial hydronic heating and cooling applications as well. Contractors and engineers are beginning to spec and install PEX for distribution piping to various terminal units, such as fan coils, reheat coils, heat pumps, baseboard radiators and chilled beams.

However, while PEX is thoroughly tested and proven in the field, it can sometimes be misunderstood. Many wonder if a plastic pipe can really compete with, let alone outperform, metallic piping in these types of applications.

So, to make it easy, I’ve outlined a few important facts you should know before installing PEX in a hydronic distribution piping application.

All PEX is not the same

Professional PEX products fall into three categories: PEX-a, PEX-b and PEX-c. Of those three, PEX-a, manufactured using the Engel Method, has the highest degree of consistent crosslinking — at 80 percent. This produces a pipe that is more flexible and more durable with thermal and elastic memory properties.

Understanding thermal and elastic memory

Thermal memory is the ability to repair accidental kinks in the PEX-a piping with a controlled heating source, such as a heat gun. The controlled heat quickly eliminates the kink in minutes, while the pipe is restored to its original durability.

Elastic memory refers specifically to how PEX-a piping will quickly return to its original dimensions after expansion. This allows the use of the exceptionally strong, ASTM F1960 fitting connection.

In creating a PEX-a connection, the installer uses a specially made expansion tool to enlarge the diameter of the pipe, so that a fitting with a slightly larger internal diameter can be inserted. The pipe quickly compresses over the fitting, creating a durable connection that actually strengthens over time.

Just as important: Because the fitting diameter is a bit larger than the pipe diameter, “dry-fit” pipe connections are physically impossible. This eliminates the problem when an installer neglects to solder or glue a fitting in a copper or CPVC system, resulting in costly leaks inside the walls of a completed project. An ASTM F1960 fitting requires the connection be fully made, permitting quick visual confirmation.

The difference with expansion fittings

Unlike with metallic pipe, an expansion fitting is actually the strongest part of a PEX-a system. It will not leak. In fact, pull testing shows that even 3,000 pounds of force with over 13 inches of displacement does not compromise the integrity of the ASTM F1960 PEX-a connection. In all likelihood, there would be a catastrophic failure of the building structure before enough force is applied to break that connection.

Using hangers and supports

PEX-a pipe can be hung at similar intervals as metallic pipe. It’s true that other plastic piping systems typically require supports every 32 inches. Some manufacturers, however, offer PEX-a pipe supports — a galvanized steel channel that provides continuous support in suspended-piping applications. This support allows PEX-a to behave just like a metallic piping system in many ways, including hanger spacing: ½-inch and ¾-inch PEX-a pipe can be hung at 6-foot intervals; 1-inch through 3-inch pipe, at 8-foot intervals.

Addressing expansion and contraction

The PEX-a pipe support controls the natural expansion and contraction that occurs as the piping heats and cools. Used in conjunction with manufacturer-recommended installation practices, the pipe support allows PEX-a to undergo an expansion rate equal to or, in some cases, less than that of copper.

Temperature and pressure considerations

PEX-a is rated for continuous operation at 200°F at 80 psi. Any hydronic application with water temperatures at or below this value is perfectly applicable for the product.

Fire-resistant construction ratings

PEX-a is ASTM E84-rated for flame- and smoke-resistance inside a non-ducted, return-air plenum. This also applies to fire stopping. For more information regarding these listings, please contact the manufacturer.

Codes and standards compliance

PEX-a is compliant with all codes and standards that pertain to it, be they in the International family (IBC, IRC, IMC, IPC) or the Uniform family (UMC, UPC, CPC) of U.S. Codes.

To learn more about Uponor’s solutions, visit uponor.com.

Kim Bliss is the content development manager at Uponor. She can be reached at kim.bliss@uponor.com.

Kim Bliss is the content development manager at Uponor. She can be reached at kim.bliss@uponor.com.