https://youtu.be/MhqypPXJtxM?si=h-FhMaoiuUVe3c4w Frozen Tundra no longer. Mechanical Hub’s Hub on the Road series takes us to Lambeau Field. Lambeau’s mechanical contracting partner, Tweet/Garot, gives us a behind-the-scenes look at Lambeau’s mechanical room, which serves as the epicenter for snowmelt, field heat, and HVAC, as well as its prefabrication facility in Wrightstown, Wis Read more

snowmelt

Frozen Tundra no longer. Mechanical Hub’s Hub on the Road series takes us to Lambeau Field. Lambeau’s mechanical contracting partner, Tweet/Garot, gives us a behind-the-scenes look at Lambeau’s mechanical room, which serves as the epicenter for snowmelt, field heat, and HVAC, as well as its prefabrication facility in Wrightstown, Wis.

https://youtu.be/XDv7qrBBZdg Mechanical Hub takes you to Salt Lake City as they visit with Bob Dudley, co-owner, Harris-Dudley Plumbing & Heating. Bob talks about the company and its reliance on snow. A great part of his business in providing radiant, hydronics and snowmelt systems to the Park City clientele Read more

Mechanical Hub takes you to Salt Lake City as they visit with Bob Dudley, co-owner, Harris-Dudley Plumbing & Heating. Bob talks about the company and its reliance on snow. A great part of his business in providing radiant, hydronics and snowmelt systems to the Park City clientele.

I know it’s the start of summer and you’re thinking, “who is thinking snow and cold temps?” But it could be the best time to ramp up your snowmelt game for the upcoming winter season. Once upon a time, commercial snowmelt systems lived independently, with little concern about the larger mechanical environment they were often a Read more

I know it’s the start of summer and you’re thinking, “who is thinking snow and cold temps?” But it could be the best time to ramp up your snowmelt game for the upcoming winter season. Once upon a time, commercial snowmelt systems lived independently, with little concern about the larger mechanical environment they were often a part of. Typically, a boiler provided heat and a smart tubing layout, properly circulated, offered thermal distribution.

Voila! As if by magic, tropical warmth gently melted away midwinter precipitation from parking lots, walkways, ramps and driveways.

All good things change, and occasionally for the better. As for modern snowmelt systems, their renaissance has come in the way of—you probably guessed it— improved and more sophisticated controls. Now, snowmelt systems can integrate with BAS (building automation systems).

It only makes sense that snowmelt systems would eventually cross that bridge. Getting there, however, wasn’t without challenge.

BAS networks, by design, are largely “inclusive.” That is, their purpose in life is to integrate, control and monitor as many of a building’s key functions as possible, including heating, cooling, ventilation, lighting and other important operations.

Yet, because snowmelt systems operate outside a building, and are exposed to ambient conditions outside the envelope—with conditions that change quickly, often requiring far more than simple on/off function—BAS systems are challenged by their limitations. The key frustration expressed by design engineers, installers and building owners alike is that the ever-changing nature of outside, ambient conditions defies the constraints of most automated controls.

For this reason, anyone attempting to tie commercial snowmelt function with a BAS confronted a giant hurdle.

Fortunately, those impediments may now be things of the past.

The nature of the beast

For the longest time, achieving proper connection to and communication between snowmelt controls and a BAS was the seemingly impossible task. The two key parts of that puzzle were a.) sensors didn’t want to communicate digitally with the BAS, and b.) controls were mostly incapable of anything more than on-off operation. Maintaining idle operation, controlling gradual increases in temperature, or especially measured deactivation—these became the key challenges.

After all, if snowmelt system deactivation happens too soon, winter accumulations may pile up, or snow may melt prematurely, turning into treacherous ice. Or, if a system demands too much heat, or stays on too long, it punishes the building owner with unexpected operational costs.

For many years, there were many reverse-engineered attempts to connect snow and ice sensors with building automation systems. However, more recently, new technology has been developed to meet this challenge.

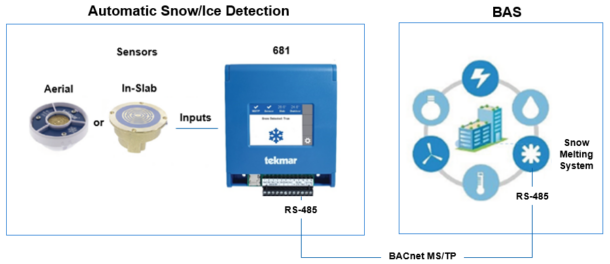

This new technology helps connect these two previously disconnected functions by receiving input data and sending information from sophisticated sensors directly to the building automation system, which ultimately tells the snow melting system to turn on or off.

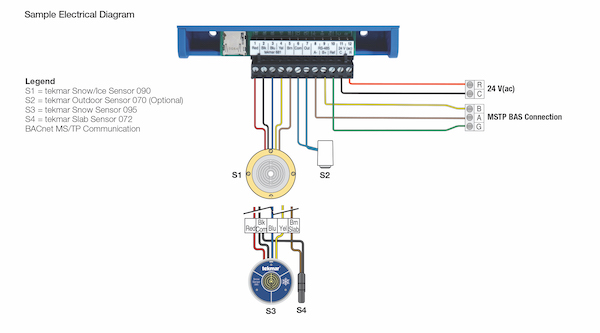

A snow and ice sensor interface communicates directly with a BAS controller through BACnet MS/TP protocol, letting the BAS know to engage the on and off function of a snowmelt system when the outside sensors detect snow or ice. This unique piece of technology has quickly turned a traditionally inefficient process into a smart and truly automated system.

Having the ability to interface snow and ice sensors directly with any BACnet controller is not only creating more efficient snow melting systems for facility and building owners, it’s making it easier for contractors to have a simple, standard solution that can be easily applied to any snowmelt job—without custom coding or complex installation.

Having the ability to interface snow and ice sensors directly with any BACnet controller is not only creating more efficient snow melting systems for facility and building owners, it’s making it easier for contractors to have a simple, standard solution that can be easily applied to any snowmelt job—without custom coding or complex installation.

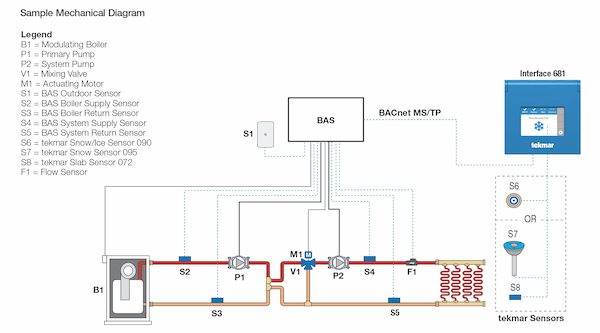

Despite its simplicity, connecting a snow and ice sensor interface to a BAS should incorporate many functions, also known as objects (see bullets below). The device itself is designed to be installed in a mechanical room, or at any remote location on site—perhaps in a service room closer to the snow melting area.

The list of data objects shared with the BAS controller should ideally include:

- Snow or ice has been detected

- Snow or ice has not been detected

- Outdoor air temperature

- Slab temperature

- Slab target temperature

- Snow/ice sensor sensitivity

- Warm weather shut down (WWSD)

- Cold weather cut off (CWCO)

- Error codes

As is often the case—and especially when new technology is introduced—questions arise. Here are some common questions from professionals in the field:

What happens if ambient conditions are too cold, or too warm?

Interface features such as warm weather shut down (WWSD) and cold weather cut off (CWCO) are particularly useful in ensuring the snow melting system is only running when needed. For instance, with CWCO, when outdoor air temperature is too cold (below CWCO setting), the BAS heat source is not able to increase the slab temperature to melt snow or ice. Features like this create critical efficiencies and save loads of energy.

With the right technology in place, the interface sends a signal to the BAS to turn off the snow melting system. Once the outdoor air temperature increases above the CWCO temperature setpoint, the interface will communicate to the BAS to turn on the snow melting system and resume its operation.

Of course, if conditions are too warm for the formation of snow or ice, the systems will use the opposite logic (WWSD) and tells the BAS to deactivate the system.

What types of alert functions are available to building managers?

Ideally, a snow and ice sensor interface will use error codes to signal the BAS controller if there are operational problems with the sensors.

This would allow the BAS to have feedback on the system and determine if any action needs to be taken.

Can contractors use the BACnet Sensor Interface with any snowmelt application controlled by BAS controllers?

Here, too—a versatile snow and ice sensor interface should be compatible with any snowmelt system application. After all, BAS controllers use BACnet MS/TP protocol for communication. The technology should be capable across many types of installations, such as snowmelt applications with a simple dedicated boiler, or more complex multi-boiler plants with multiple zones and mixing valves. And, the right technology should be BTL certified, providing the confidence of seamless integration.

Here, too—a versatile snow and ice sensor interface should be compatible with any snowmelt system application. After all, BAS controllers use BACnet MS/TP protocol for communication. The technology should be capable across many types of installations, such as snowmelt applications with a simple dedicated boiler, or more complex multi-boiler plants with multiple zones and mixing valves. And, the right technology should be BTL certified, providing the confidence of seamless integration.

Why is it important to control the slab temperature?

Controlling slab temperature is crucial to have an efficient snowmelt system. If the slab temperature is too low, the snow will not melt off. If the temperature is too high, the slab could be damaged and will waste a lot of energy.

Information = power

So, if you’re faced with the need to install—or retrofit—a commercial snowmelt system, and BAS is in the cards, you’re now equipped with new information and ready to reenter winter warfare. But this time, better prepared.

Cleber Alves is product manager for tekmar.

tekmar Control Systems has announced the addition of four new switching relay and zone valve control models to their existing line of zone control solutions. tekmar now offers 2-zone pumps, 3-zone pumps, 3-zone valves, and 5-zone valves. The newly added switching relays and zone valve controls are compatible with all low-voltage thermostats and offer a Read more

tekmar Control Systems has announced the addition of four new switching relay and zone valve control models to their existing line of zone control solutions.

tekmar now offers 2-zone pumps, 3-zone pumps, 3-zone valves, and 5-zone valves. The newly added switching relays and zone valve controls are compatible with all low-voltage thermostats and offer a variety of benefits for homeowners. These include unlimited expansion; exercising, which prevents pumps from seizing during the summer; zone priority; and priority override to protect homes from freezing over the winter months.

The switching relays and zone valve controls also send out a RoomResponse™ signal to automatically adjust boiler temperatures to improve comfort, conserve energy and save money.

Learn more about switching relays and zone valve controls by tekmar and see the complete lineup of 1-6 zone pumps and 3-6 zone valves at www.tekmarcontrols.com/products/zoning.html.

Summertime is the perfect time to line up your snowmelt projects and installations heading into the upcoming unpredictable weather patterns of the changing seasons. For Jason Ridgeway, owner of Ridgeway Home Services, West Chicago, Ill., a provider of indoor home comfort services for the Chicagoland area, snowmelt has been added to his comfort portfolio, and Read more

Summertime is the perfect time to line up your snowmelt projects and installations heading into the upcoming unpredictable weather patterns of the changing seasons. For Jason Ridgeway, owner of Ridgeway Home Services, West Chicago, Ill., a provider of indoor home comfort services for the Chicagoland area, snowmelt has been added to his comfort portfolio, and an additional technology he encourages potential HVAC customers to pursue. “What used to be a popular choice for larger homes, snowmelt is becoming more commonplace in ‘regular’ sized homes in the area,” said Ridgeway.

Ridgeway was called to the near west suburban neighborhood to install snowmelt for a residence’s driveway/walkway, and in addition, believe it or not, a miniature railroad/train track system—which still runs, by the way—that meanders throughout the customer’s property.

The original homeowner decided to install the train tracks in the yard for his children and grandchildren, and when he sold the home to the current owner, “the railroad had become a neighborhood institution of sorts, with neighbors pleading to keep the landmark train system, and keep it operational,” said Ridgeway.

The project began with paving contractors removing the tracks and labeling them accordingly, while a welder repaired the tracks and fitted them atop the tubing, which was installed later.

The project began with paving contractors removing the tracks and labeling them accordingly, while a welder repaired the tracks and fitted them atop the tubing, which was installed later.

Ridgeway began the snowmelt project in September of 2017, adding the “oomph” behind the system in the basement mechanical room. Prefabbed in his shop, Ridgeway constructed the mechanical panel, which consists of Grundfos circulators, an Axiom filling station, tekmar controls for the brains behind the snowmelt system sensing, and an HTP Elite 399 boiler—installed onsite. On a side note, Ridgeway left stub outs on the boiler panel in the event of upgraded in-home radiant heat, or in the case of a future boiler change-out.

Covering approximately 3,000 sq. ft. of outdoor space—with approximately 4,500 linear ft. of REHAU PEX tubing—which includes the area of the tracks, driveway and walkways, Ridgeway began the multiple week installation—due in part to an arduous concrete pour and curing timeline—with time to spare for the upcoming winter months.

Covering approximately 3,000 sq. ft. of outdoor space—with approximately 4,500 linear ft. of REHAU PEX tubing—which includes the area of the tracks, driveway and walkways, Ridgeway began the multiple week installation—due in part to an arduous concrete pour and curing timeline—with time to spare for the upcoming winter months.

Ridgeway came away impressed with the ease of the tubing installation with both the PEXGUN installation tool, an automatic, lightweight and compact hand-held tool that attaches PEX pipe to rebar or wire mesh, and his commitment to REHAU products, in this case, the tubing uncoiler. “With the PEXGUN tubing installation tool, and REHAU uncoiler, I personally can put down 300 ft. of tubing, the same as three guys using zip ties in equal amount of time or better. The extra plus is that I don’t have to go back and cut off the tails when I’m done,” said Ridgeway.

The supply water temperature was set to 160 F with the slab melting temperature set point at 34-36 F. The cold-water shutoff was set to -10 F.

The intelligence of the system is controlled by a tekmar 090 snow and ice sensor and a tekmar 665 snowmelt control system. Basically, the in-ground sensor—used in conjunction with the tekmar snow melting controls—“senses” the precipitation and intuitively correlates the freezing or below freezing temperatures and automatically detects precipitation as snow or sleet on the applicable surface, which tells the system to activate.

The intelligence of the system is controlled by a tekmar 090 snow and ice sensor and a tekmar 665 snowmelt control system. Basically, the in-ground sensor—used in conjunction with the tekmar snow melting controls—“senses” the precipitation and intuitively correlates the freezing or below freezing temperatures and automatically detects precipitation as snow or sleet on the applicable surface, which tells the system to activate.

The tekmar 665 control uses the snow/ice detection sensor in order to automatically melt snow using Pulse Width Modulation and slab outdoor reset to maintain slab temperature. It is capable of controlling a single boiler, a system pump, and providing a signal when melting is enabled.

The existing system is one zone but is set up for the possibility of adding multiple zones, which is advantageous to Ridgeway. He will be going back to the residence to add snowmelt to existing pavers around the pool area in the back of the house. This added snowmelt will pull hot water from the existing HTP boiler.

The existing system is one zone but is set up for the possibility of adding multiple zones, which is advantageous to Ridgeway. He will be going back to the residence to add snowmelt to existing pavers around the pool area in the back of the house. This added snowmelt will pull hot water from the existing HTP boiler.

Ridgeway ran into one challenge during the installation when the system, upon initial start-up, kept experiencing a drop in pressure. Initially thinking there was a leak in the lines somewhere, Ridgeway eventually resolved the issue by diagnosing the problem, finding an unusually high content of air in the system. An elongated purging of excess air in the system solved that minor glitch.

The end result is a beautifully paved snowmelt area, complete with added railroad tracks crisscrossing through the driveway. Needless to say, when all was said and done, and a full season of experiencing snowstorms, ice and a wintry mix in between, the end result was one happy homeowner.

The end result is a beautifully paved snowmelt area, complete with added railroad tracks crisscrossing through the driveway. Needless to say, when all was said and done, and a full season of experiencing snowstorms, ice and a wintry mix in between, the end result was one happy homeowner.

Manifold images: All REHAU manifolds are pressurized to 80psi.