Complex hydronic systems are so 2008, at least according to Mechanical-Hub ProStaffer Andy Mickelson, who owns Mickelson Plumbing and Heating in Missoula, Mont. His three-man shop does plenty of high-end residential work, and even here—no—especially here, their recipe for success, serviceability and efficiency includes a heavy dose of “keep it simple.” On a custom home Read more

snowmelt

Complex hydronic systems are so 2008, at least according to Mechanical-Hub ProStaffer Andy Mickelson, who owns Mickelson Plumbing and Heating in Missoula, Mont. His three-man shop does plenty of high-end residential work, and even here—no—especially here, their recipe for success, serviceability and efficiency includes a heavy dose of “keep it simple.”

On a custom home, where some contractors may be tempted to stack the material list high and deep, Andy does the opposite. He takes a step back from the blueprints and figures out how to use the fewest components needed without any compromise. Numerous zones, DHW production, multiple supply temperatures and snowmelt loops can and are all handled without making things more complicated.

“There are a number of things you can do to keep systems simple,” said Mickelson. “I make sure to avoid ‘inadvertent’ redundancy: that is, two products that accomplish the same task.

Proper sizing of radiation, pipe, pumps and boilers accurately is obviously important, too. Picking a control system that accomplishes what you need and nothing more is helpful.

Another thing we began doing a few years ago—and have noticed an improvement since – is sizing and grouping our zones to the capacity of a specific pump, instead for creating a zone with no real parameters, and trying to find a pump that fits the zone or zone group.”

Like a round peg in a round hole, selecting your circulator first can save a lot of trouble, as well as the issues that come with over- or under-pumping a system.

Starting in late October of last year, Mickelson was hired for a job that would test his ability to “keep it simple.”

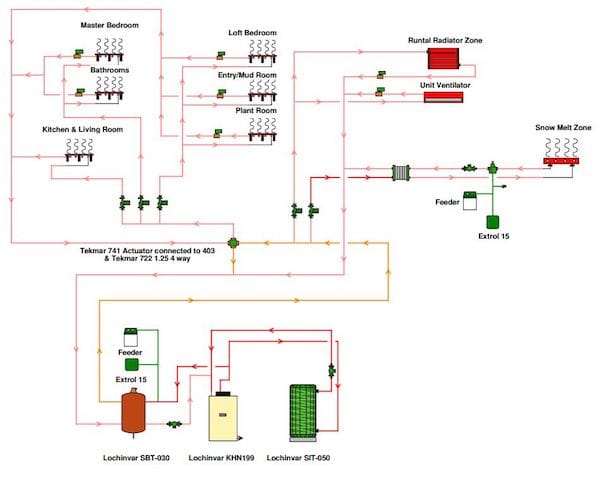

Mickelson’s work included installation of a mod-con boiler, seven zones of in-floor radiant, a hydronic unit ventilator, high-temp baseboard and 400 sq.-ft. of snowmelt.

Just out of town, the customer had purchased a nice lot with an older, 800-sq.-ft. home. The house was leveled and the basement foundation was re-used. The plan was to build a new 5,000-sq.-ft., two-story home on top of and around the original foundation.

Pick the pump first

“Like we do on all our jobs, I interviewed the homeowner long before we started the work, in order to really understand what they wanted,” said Mickelson. “Comfort was paramount, and budget not as much. So a thin concrete slab covers all radiant tubing, which is set at nine-inch centers.”

Before Mickelson started his loop layouts, he chose the Taco VT2218 variable speed circulator to serve all of the zones, with a total of six pumps. Additionally, Taco 007e single-speed ECM circulators are used on the 200 MBH fire-tube boiler and the indirect water heater.

“I like a Delta-T pump on a job like this, but another reason I used the VT2218 is for its broad pump curve, and we made use of it,” explained Mickelson. “It’s also very easy to program. Each radiant pump serves a group of zones. The zones are paired up according to the pump’s capacity, in terms of both head loss and flow rate. That way there aren’t any extra, underutilized circulators.”

Once the pump has been selected and the heat loss has been completed, the zones can be designed to fit the home. A common misconception about radiant circuits is that they must be as close to 300 feet long as possible, this just isn’t true. By dropping the length of each circuit, the head loss can be comfortably managed. The downfall to this is that the zone may require more circuits, but honestly the difference between five circuits and seven is minimal. It’s the same amount of tubing, no real noticeable increase in labor, just a larger manifold and a manageable head loss.

Low temp

Through zone valves, each pump supplies the appropriate amount of water and heat to a Watts Radiant stainless steel manifold, located remotely. Half-inch Watts RadiantPERT tubing was laid out before the gypcrete was poured.

“We chose the PERT instead of PEX because the radiant work was done throughout the winter. With spells of sub-zero weather, the increased flexibility of PERT was a huge benefit, especially considering our tight tube spacing.”

Because of the hydronic radiators, unit ventilator and snowmelt, the boiler maintains the buffer tank at 140°F at an outdoor design condition of -15°F. To make low temp water for the radiant zones, a Watts 4-way mixing valve with a tekmar 741 actuating motor was used. The 741 communicates with a tekmar 402 House Control in order to supply the exact radiant temperature need based on the outdoor temperature.

“The mixing valve sets the final delivery temp to all the low-temp zones,” said Mickleson. “It’s one of three elements at play here that really allow us to provide the exact temperature and flow rate to the radiant zones, so we’re really capitalizing on the primary/secondary piping, and squeezing every last ounce of comfort and efficiency out of the system. The other two elements are the outdoor reset on the higher temp boiler zones, and the variable-speed, Delta-T pumps. They all work hand in hand.”

The home has several areas with structural elements which made installing some of the tubing a challenging. Because of this, Mickelson had no choice but to run PEX supply and return piping through exterior walls. As a guard against the challenge of Montana winters, he wanted to run a glycol solution in the system. He installed a Neutra-Safe system feeder, which is an all-in-one reservoir, pump and control.

The home has several areas with structural elements which made installing some of the tubing a challenging. Because of this, Mickelson had no choice but to run PEX supply and return piping through exterior walls. As a guard against the challenge of Montana winters, he wanted to run a glycol solution in the system. He installed a Neutra-Safe system feeder, which is an all-in-one reservoir, pump and control.

High temp

The fourth and fifth VT2218 circulators serve the home’s three high-temp zones directly out of the buffer tank. In the basement, where the existing, uninsulated slab is still in place, Runtal baseboard was used in lieu of radiant tubing. Mickelson had considered ceiling radiant, but there wasn’t enough height to allow it. The circulator used for the baseboard zone also supplies water to the 12,000 BTU Smith Environmental unit ventilator in the garage attic.

The last variable-speed circulator serves as the snow melt system pump on the loop side of the brazed-plate heat exchanger. Mickelson uses a tekmar 654 Snowmelt Control to manage automatic operation and maintain a 25°F Delta-T across the 400 square-foot zone. This control features a snow and ice sensor that’s set in concrete when poured. The snowmelt loops also utilize a second Neutra-Safe System Feeder.

“Because of the components used and a thoughtful design, we’re covering five different loads with one boiler while installing it in a relatively tight space, all without being overly complicated,” said Mickelson.

Each pump supplies the appropriate amount of water and heat to a Watts Radiant stainless steel manifold.

“In the case of an emergency, I only have to deal with a single control system or one replacement pump,” he added. And with all that said, I can’t think of a quieter, more comfortable, or higher efficiency heating system.”

Mickelson is now going over a punch list, and looking forward to the feedback from the customer. He’s expecting rave reviews about the comfort level, and complete satisfaction when the owner receives their first propane bill.

Fellow Hydronic Professionals,, I have been the director of the RPA now for 2 and 1/3 years. It has been an arduous journey, with some ups and some downs, mostly ups, but we (I especially) do this for the industry. We now have in place one of the most dynamic group of people (members on Read more

Fellow Hydronic Professionals,,

Fellow Hydronic Professionals,,

I have been the director of the RPA now for 2 and 1/3 years. It has been an arduous journey, with some ups and some downs, mostly ups, but we (I especially) do this for the industry.

We now have in place one of the most dynamic group of people (members on committees and members in general) and are kicking butt and taking names. We have an actual Hydronics/Radiant Code that is part of the Uniform family of codes (Uniforms Solar Energy Hydronics Code) and are in the final stages of developing an ANSI recognized, ASSE developed Professional Certification program for designers and installers.

We have and continue to add instructors to, our online university, RPAU, with HeatSpring offering some of the best instructors time and money can buy, making education of yourself and your employees available at YOUR convenience.

We recently inked a deal with Tom Grandy and Associates to help show experienced contractors how to turn their hard work into a good profit margins so they can retire comfortably or live well before retirement.

We have inked a deal with Kilowatt Financial to provide low interest, high dollar (up to $30K) financing IN THE CONSUMERS HOUSE. (less than 30 minute approvals online)

We have renewed commitments from UPS offering our members a significant discount on shipping less than truck loads.

We have a monthly newsletter available to members only.

We have printed magazines to help you sell radiant comfort (walls floors and ceilings) to the consumers.

We have monthly Lunch and Learn webinars to keep you abreast of the latest and greatest in our industry.

We have HydroniX Talk (which is on summer vacation) which is also available to members only, and will now be taking place early evenings during the week, beginning this coming fall, featuring the likes of Dan Holohan and many other notable hydronics pioneers.

All of this for a contractor for less than $1.00 per day (actually less than that because the $300/year fee is good for 3 employees) as well as access to some of the best minds this industry has to offer (locked access LinkedIn accounts).

And we continue to look for ways to promote this wonderful industry of ours so that we can prove to the world something that most people here have known for a long time, that being that hydronics is THE most efficient method of transferring energy from point A to point B, or from point B to point A.

We have legislative power in Washington DC looking out for our industry’s interests. (The old RPA was not allowed to lobby)

There’s only one major missing component…..

>>> YOU! <<<

I and my membership committee (and the other 7 committees) are baffeled as to why former members of the old RPA and new potential members are not coming back into the fold.

So, I’d like to ask some questions and clear up some rumors.

Rumor 1: IAPMO runs the RPA. Wrong, WE run the RPA. IAPMO owns it lock stock and barrel, and provides us with all of the tools and support we need to further its goals, but the RPA is run by its members. It is an organization OF the members, BY the members, FOR the members.

Rumor 2: RPA is dead. Wrong, it came extremely close to going under during the economic down turn, and if IAPMO had not intervened, it would have gone down in flames. Fortunately, IAPMO caught it before it plowed into the ground, gave it a soft landing, re-painted the plane, refueled it and sent it back up into the air.

Rumor 3: IAPMO is dead. This couldn’t be further from the truth. IAPMO is the largest CDO (Code Development Organization) in the world. In fact they are expanding and now have offices around the world, helping to establish plumbing and mechanical codes around the world.

Rumor 4: IAPMO and the RPA are too big for me to consider joining. WRONG, these organizations are here to support you, not fight you. Every code and standard that is developed by these organizations are done so under a very tightly watched and controlled ANSI Open Consensus process. No complaint goes unattended or ignored. All concerns are addressed until there are no more concerns.

So, my question to you is why have you (contractors, designers, installers, equipment manufacturers, manufacturer rep agencies and others) not joined, or rejoined this fantastic organization? There is strength in numbers, and if we as an industry don’t band together real soon, there is a real possibility that our industry will be put out of business by some very savvy foreign interests who have stated publicly that their intent is to take over ALL methods of heating and cooling.

Tell me what rumors you’ve heard, or why it is that you haven’t joined this organization. We are all ears, and we want to make certain that this machine is your machine, and that it does work for YOU, the industry.

I’d also like to thank all of our volunteers and our board of directors for their guidance in getting the ship to this point. Without your help, we wouldn’t have gotten this far. THANK YOU.

Now, tell me what your concerns are?

If you’d like to join, go to www.radiantprofessionalsalliance.org and click on the JOIN button, or simply call Alan Wald, our Vice President of Memberships at 909-472-4211and he or one of his staff can get you signed up over the phone. Easy squeasy lemon peasy.

Thank you for your consideration, and thanks to the Mechanical Hub for being a member and allowing us to use this venue.

Mark Eatherton

Executive Director, Radiant Professionals Alliance

18927 Hickory Creek Drive, Suite 220

Mokena, IL 60448

Desk: 708-995-3001

Toll free: 877-427-6601

www.radiantprofessionalsalliance.org

Email: mark.eatherton@radiantprofessionalsalliance.org

The great experiment with with my radiant driveway is continuing. First some background: At Reisssmann Plumbing, we have done many driveways and walkways over the years, all the way up to a 5-zone, 6,000-sq.-ft. driveway whose owner calls every year after a snowfall to tell me how appreciative he/she is for having it installed. The Read more

The great experiment with with my radiant driveway is continuing. First some background: At Reisssmann Plumbing, we have done many driveways and walkways over the years, all the way up to a 5-zone, 6,000-sq.-ft. driveway whose owner calls every year after a snowfall to tell me how appreciative he/she is for having it installed.

The problems I had with my 8,500-sq.-ft. parking lot and driveway are numerous. Plowing is a pain, as I have to move all of the trucks so I have somewhere to push the snow. If we get rain, it freezes at night when the temps drop. When the sun comes up—being so low at that time of the year—the trees shade parts of the driveway, leaving it slippery—salt is the only option.

The short part of the driveway that slopes down to the entrance to the office is particularly dangerous when everyone comes to work so, again, it’s the salt option that has to start at about 5 a.m. to do any good.

We decided to solve the problem with 14 zones. We had 13 initially but added a single loop at the end of the driveway—at the end of the road—to deal with snowplows. This gave us the opportunity to apply heat where it is needed without turning entire driveway on. The average cost—with the snowfall we had last year—was about $100 per snow. This is without controls, as I am still working on them, so I expect this number to come down.

Last year we had two snowfalls per week so I was able to do a lot of testing. For example, I tried waiting until there was 1″ of snow before turning on the system. It took one hour from a cold start to see where the tubing was and three hours to all black, which is totally acceptable.

One of the problems with heavy tubing—5/8″ and up—is that is does not bend well or fasten down easily. we used 1/2″ tubing—yes you read it correctly: 1/2″—with loops no longer than 200 feet. The system operates from three sheds outside. The main one has three Triangle Tube Prestige 399 boilers integrated in the cascade format. All air elimination an expansion happens there. The 2″ PEX lines go to each of the other sheds with a feed and return loop using primary/secondary supplying heat to each of the secondary – primary/secondary loops, one in each of the other sheds. They then send heat to each of the manifolds, which are located in sprinkler boxes along the side of the parking lot and driveway. There are no pumps outside; all are located in the sheds. All of the pumps and zone valves are Taco and all of the tubing is Uponor.

Reliability is key with snowmelt. It’s not a quick service call to fix a heat zone. When someone has paid a lot of money to put a snowmelt system in, there is no option for failure. I have use Taco and Uponor for many years without a problem. (Jeff Weidemann, the multi-talented genius from Uponor and John Barba from Taco were both a great help to me.

This was my first venture into Triangle Tube (TT) boilers. I reached out to friends in the business and got a “thumbs-up” on TT, especially from Bob Bona, who had put in a lot of them.

I was looking for something that would have no problem with a 50/50 propylene glycol mix, and be extremely reliable. Roger, my chief tech and right arm, and I visited the TT factory in South Jersey. I was impressed with what I saw. No corners were cut on using the best materials available. I bought the system with their solid manifold set up for the boilers, and I could not be more pleased. It assembled well and it is very sturdy. Once it was attached to the system, I got a crash course at setting it up, as we were due for snow that same night. I reached one of TT’s tech support people after 5 p.m. and he walked me through getting them going. After the initial information was entered, they literally set themselves up. Very nice.

Last summer, I added a pool kit from Energy Kinetics, who by the way, make a great boiler, too. This heat exchanger and controls allow me to take the heat from my driveway in the summer and use it to heat my pool. The driveway takes precedence for the heating, and if more heating is needed, the pool heater kicks in. I have an override if I have to heat the pool quickly for a party, and found that I could even kick in the TT boilers as an assist, reaching an amazing heat-up speed for the pool of multiple degrees per hour, and bringing the pool heat by 10 degrees in a very short time. Not bad for 50,000 gallons.

The controls are what I am working on now. The pool uses a Hayward Aquaconnect computer to give me iPhone access for control. I use salt water and it keeps the pool perfect at all times without chemicals. It paid for itself in a few years. I like the Web access and plan controls that I can control myself from anywhere.

As you know, it is difficult to do ANYTHING for yourself when you have a business; your clients take precedence. I only get to do this to try it out before I sell it.

We already put Internet access in all three sheds while we were laying the driveway. I am currently looking at ControlWeb.com, which has a nice array of controls. I will pass on my findings and get back to you with another report once I have it complete.

http://vimeo.com/87493092 Hub friend Derek Moore, president, Reissmann Plumbing & Heating Inc., gives a glimpse of a recent residential snowmelt installation. This very cool time-lapse video shows the entire project from start to finish. Reissmann Plumbing & Heating, Inc., Chester, N.J., is a full service plumbing and heating company serving Morris County and the surrounding areas Read more

Hub friend Derek Moore, president, Reissmann Plumbing & Heating Inc., gives a glimpse of a recent residential snowmelt installation. This very cool time-lapse video shows the entire project from start to finish.

Reissmann Plumbing & Heating, Inc., Chester, N.J., is a full service plumbing and heating company serving Morris County and the surrounding areas of New Jersey since 1966.

The new Danfoss OJ ETO2 Snow Melt controller offers an intelligent all-in-one control solution for ice and snow melting suitable for any application which uses hydronic or electric heating, including driveways, parking lots, sidewalks, stairs, ramps, bridges, and more. Optimal operation is ensured through output control, making the system both effective and economical. ETO2 offers Read more

The new Danfoss OJ ETO2 Snow Melt controller offers an intelligent all-in-one control solution for ice and snow melting suitable for any application which uses hydronic or electric heating, including driveways, parking lots, sidewalks, stairs, ramps, bridges, and more. Optimal operation is ensured through output control, making the system both effective and economical. ETO2 offers an environmentally friendly method of snow melting by eliminating the need for chemical treatments.

By using data received from the snow melting system’s temperature and moisture sensors, the controller ensures that the system is only energized when snow or ice are detected – enabling proficient management of energy consumption while keeping areas free of ice and snow. An easily operated encoder button and backlit graphic display ensures quick and easy configuration and simple indication of temperature, status, etc.

The ETO2 can control up to two zones by activating an individual output for each zone. In a 2-zone hydronic application, these outputs are connected directly to circulation pumps. For 1-zone hydronic systems, the ETO2 ensures the required supply water temperature by regulating a motorized mixing valve in response to supply water temperature.

The advanced technology of the ETO2 has many benefits including improved efficiency, productivity, safety, and reliability in residential and commercial applications. Despite winter weather, the ETO2 aides in the prevention of highly dangerous icy walkways, public roads, bridges, commercially owned parking lots, loading platforms, and more. Save maintenance costs of shoveling, plowing and salting, and offer safe building access to residents, customers, visitors, and employees with the Danfoss OJ ETO2 Snow Melt Controller.