I was talking the other day with my buddy who lives northern Wisconsin on the topic heat pump water heaters (HPWHs). You see, he is in the market for a water heater and was asking my advice on those particular units. Wanting to know more myself, I pulled up some info and the more in-depth Read more

Sustainability

I was talking the other day with my buddy who lives northern Wisconsin on the topic heat pump water heaters (HPWHs). You see, he is in the market for a water heater and was asking my advice on those particular units. Wanting to know more myself, I pulled up some info and the more in-depth I got, the more I wanted to know. Cold weather performance, special ducting, size of mechanical space, accessibility to air, cooling and conditioning of adjacent space are all very important topics of discussion.

But, wait a minute, I thought to myself, I can use some of my “superpowers” as an editor in the trades these past 20+ years to ask people who are more in the know about HPWH than me.

I recently reached out to few people I trust to give me honest assessments of these units.

Advantage Heat Pump Water Heaters

According to Eric Aune, Aune Plumbing, Heating & Drains, there has been a ton of marketing to the public, and even more incentives for installation. “Local utilities are offering rebates upwards of $2-3K in some places, and here in Minnesota, we aren’t seeing rebates that high but it’s clear why the rebates are offered—because its lowering and spreading the load on the grid over longer periods at lower consumption rates. The utilities are trying to stay in front of or (most likely) catch up to the growing demand and stress on the grids all across the country. HPWH’s are one piece to the puzzle.”

John Siegenthaler, P.E., Appropriate Designs, gives three bona fide advantages for HPWHs: One, they are excellent for capturing “surplus heat” (e.g., heat that’s present but not generated by another heat source for the purpose of warming the space). For example, solar heat gain to a garage, or heat generated by computer servers. Two, when properly applied, they can generate a given amount of DHW on about 1/3 the electrical input required by a standard “resistance type” electric water heater (tank or tankless). And three, some models are available that can operate on 120 VAC power, whereas all electric resistance water heaters require 240 VAC power.

But in Cold Climates?

But are these units considered more inefficient the more you climb the northern latitudes to colder climates? “Although heat pump water heaters are often placed in unconditioned spaces such as garages in southern locations, it would be a big mistake to do so in a cold northern climate where outside temperatures are below the minimum operating air temperature for the HPWH for weeks or months during winter,” says Siegenthaler. “The heating performance of any air source heat pump—ductless, central, air-to-water, HPWH, always decreases with decreasing air temperature—Putting any water heater in a cold space is not recommended. Standby heat loss would definitely increase.”

HPWHs have minimum air flow requirements, especially if placed in confined spaces, adds Siegenthaler. The I/O manual supplied with the unit should give all these requirements. “Some units allow ducting of outside air to the heat pump assembly on top of the tank, but I would only use this option in a relatively warm climate. Using ducted outside air also foregoes the cooling and dehumidifying benefit of the HPWH,” says Siegenthaler.

Living in Minnesota, Aune says, “HPWH’s capture/transfer the heat in the space surrounding them to the tank of water. When you talk about this here in Minnesota, it’s common for people to consider this inefficient since the we have to heat with a boiler or furnace, so aren’t we running our space heating system to provide heat for the water heater?

“The reality is the HPWH is able to capture and transfer a lot of energy without major negative effects on the conditioning and comfort of the space with a few considerations like ducting the less humid, colder air to the exterior of the house or even moving it with the furnace or exhaust fans,” says Aune.

According to Gary Klein, principal, Gary Klein and Associates, the majority of HPWHs sold today are hybrid HPWHs, and their efficiency is rated at 67.5 F and 50% relative humidity. “Very close to the temperature we keep the inside of conditioned buildings,” says Klein.

Klein suggests an interesting concept by managing the cold discharge air. “Install the HPWH in the basement near the space conditioning system. Use the return of that system to suck in the cold discharge air from the HPWH and distribute it throughout the house. Use a relay to link the fan to the HPWH. Let the thermostat decide if the air needs to be conditioned. Install a very large filter grille to bring air to the room where the HPWH is installed. (2-inch pleated filters).

“Need the ability to move at least 60 cfm per 100 watts of compressor, fan and control power. Warmer intake air increases the coefficient of performance (COP),” says Klein.

Siegenthaler points out that he did a column earlier this year that discussed a situation where a modern house used an air source heat pump for space heating, and combined it with a HPWH inside the house for DHW. Technically this puts the two heat pumps into a “cascade” relationship, says Siegenthaler.

“Think of the space heating heat pump as ‘feeding’ heat to the HPWH. It’s possible to show that the overall efficiency of this arrangement is lower than using a single air-to-water heat pump for both space heating and domestic hot water (DHW). I think that this is important because many builders, architects, energy planners, energy auditors, etc. don’t necessarily understand this concept. They assume that two heat pumps—one for space heating, and the other for DHW—are better than one.”

Siegenthaler stresses that the “ideal” scenario for a HPWH is to put it in a space where there’s “surplus heat.” “Don’t rob Peter to pay Paul,” says Siegenthaler.

There are plenty of such spaces, suggests Siegenthaler, especially in commercial buildings—manufacturing, heat from vending equipment or refrigeration equipment, cooking, laundry, computers, solar gain, attics that remain above 35ºF year-round, even mechanical rooms with lots of uninsulated piping, boilers, electrical transformers, greenhouses, cannabis grow houses, etc.

“Paraphrasing Patrick Henry, ‘Give me air, or give me death,'” says Klein.

The Caleffi Green was introduced to North America at the recently held AHR Expo in Chicago. The global initative defines a path forward with a multi-faceted plan of action for sustainability. An executive leadership team from the company’s Italian headquarters attended AHR to launch the initiative. Federica Beretta, Brand and Content Marketing Manager from Caleffi S.p.A Read more

The Caleffi Green was introduced to North America at the recently held AHR Expo in Chicago. The global initative defines a path forward with a multi-faceted plan of action for sustainability.

An executive leadership team from the company’s Italian headquarters attended AHR to launch the initiative. Federica Beretta, Brand and Content Marketing Manager from Caleffi S.p.A. stated, “We have launched a project called The Caleffi Green and we have been spreading it out all over the world. Sustainability is not only about processes and products, it is also about people. Every action is important.”

Caleffi’s global commitment to sustainability and resiliency is not new. Manufacturing is accomplished in an energy conscious manner, while prioritizing a healthy work environment for employees. For example, air pollutant emissions during the brass forging process are maintained 33% below the maximum particulate matter regulations in effect in Italy. More specifics can be found in the recently published Caleffi Group Sustainability Report.

As a reflection of Caleffi’s dedication to reducing its carbon footprint, a North America facility expansion will incorporate photovoltaic panels set to provide over 80% of the building’s electricity demands. In addition, over 90% of the building’s materials and labor will be regionally sourced.

Additionally, the North American group will expand the Caleffi Cares program to include a Volunteer Time Off (VTO) policy. Each member of the team has enormous potential to make an impact in their community. Milwaukee-based and remote employees have paid time to volunteer with the charities and organizations that make a positive impact in their families and communities. At the end of the year, Caleffi will hold a company-wide Lunch and Learn where employees can report on how they spent their time and share success stories.

Count on Caleffi to continue to support the industry with non-proprietary educational resources in our commitment to Excellence in Education. To design, install and service the best-case, energy efficient and water conscious systems there is no room for gaps in stakeholder training. It is in the collaboration of ideas and technologies from design to installation. We are committed to help all stakeholders achieve these lofty goals with resources such as the semi-annual idronics™ journal and Coffee with Caleffi™ webinar series.

Heating oil doesn’t have the market share of some of the other fuels, but it’s used in about 4.5 million homes in U.S. Most of these homes are concentrated in the Northeast, but heating oil is in use to some degree in almost every state in the country. And the heating oil’s market share has Read more

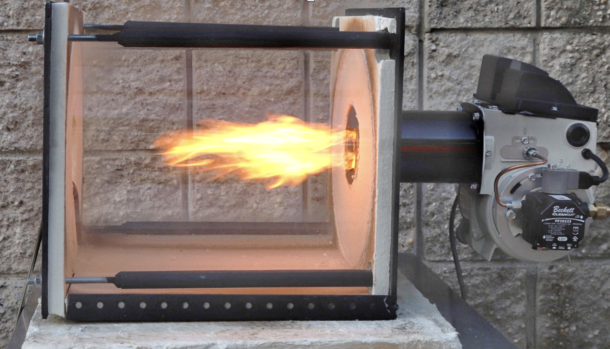

Heating oil doesn’t have the market share of some of the other fuels, but it’s used in about 4.5 million homes in U.S. Most of these homes are concentrated in the Northeast, but heating oil is in use to some degree in almost every state in the country. And the heating oil’s market share has been shrinking over time in the face of climate change and a growing global awareness of environmental issues. The home heating oil industry is undergoing a remarkable transformation.

A quiet renaissance is taking place in the industry as communities, companies and individuals turn to a cleaner and more sustainable alternative to keep their homes warm during the cold winter months, while reducing their carbon output. That alternative is renewable liquid fuels. Electrification is often touted as the only decarbonization solution when there are many viable options, including renewable liquid fuels. Utilizing all options is the prudent approach to a worldwide problem of such immense scope.

The Need for Change: From Fossil Fuels to Renewable Liquid Fuels

For decades, homeowners have relied on traditional heating oil derived from fossil fuels to combat the chill of winter and provide abundant domestic hot water. However, with the environmental impact of these fuels becoming increasingly apparent, and with government mandates for carbon reduction, the need for a greener alternative has never been more pressing. Enter both biodiesel and renewable diesel—renewable energy sources that offer a solution to reduce carbon emissions and create a more sustainable future rapidly and economically.

The Rise of Renewable Liquid Fuels

Biodiesel, made from organic materials such as plant oils, animal fats or recycled cooking oil, is emerging as a game-changer in the heating industry. Unlike traditional heating oil, biodiesel produces up to 90% less greenhouse gas emissions, making it a cleaner and more environmentally friendly option. The shift toward biodiesel aligns with the global push for renewable energy sources and a reduction in dependence on fossil fuels.

Renewable diesel is derived from the same biomass feedstocks as biodiesel but undergoes a different production process. Renewable diesel is gaining popularity as a low-carbon alternative to traditional heating fuels. Unlike conventional fuel, which is derived from crude oil, renewable diesel significantly reduces greenhouse gas emissions and promotes a more sustainable energy future. Renewable diesel is in wide use in Europe for space and domestic water heating, particularly in the UK where renewable diesel incentives and mandates are upcoming.

During the transitional phase, renewal liquid fuels are commonly blended with each other and conventional petroleum. These blends are referred to as BXX, the XX representing the portion of renewable fuel. For example, B20 would be 20% biodiesel and 80% petroleum. Blends of biodiesel and petroleum are often referred to as Bioheat®.

Initiatives Leading the Way

Manufacturers, as well as national and state associations, are taking the lead in this transition. Forward-thinking fuel dealers and individuals are driving change from the ground up. These initiatives focus on producing new burners, appliances and accessories that are rated for renewable liquid fuels, education, outreach, and the development of infrastructure to support the adoption of renewable liquid fuels for home heating.

In many cases, these initiatives are not only reducing the carbon footprint of communities but also contributing to local economic development. Renewable liquid fuel production often involves repurposing waste materials, creating new jobs, and supporting local businesses engaged in the sustainable energy sector. Utilizing waste products from agricultural production helps both the American farmer and the economy.

How to Transition?

Most fuel dealers and homeowners don’t jump immediately from heating oil to 100% biodiesel, they slowly transition the blend level upwards over time. This slow transition makes it a non-event; the homeowner and technician observe no noticeable differences and no changes in equipment are needed. As filters, gaskets and other components are replaced over time, they should be upgraded to versions rated for use with biofuels.

The same holds true for appliances—when they reach the end of their lifespan or are upgraded for efficiency purposes, renewable fuel rated boilers and furnaces should be installed. The Inflation Reduction Act (IRA) recognizes the advantages of renewable fuels and authorizes a $600 tax credit for a new liquid fuel furnace or boiler rated for at least B20.

Success Stories: Homes Heated by Biodiesel

There are more than 300,000 companies and consumers that have already made the switch to B20 or higher blends, and are experiencing firsthand the positive impact on both the environment and their wallets. Jacqueline Hart, Executive VP of Hart Home Energy in Oakdale N.Y., remarked, “Our family began injection blending biofuel more than 20 years ago because we felt it was the right thing to do to decrease our dependency on foreign oil sources and to make the environment cleaner for future generations.

Since that time, we have increased our blends, participated in every local field study conducted in our area, and have used B100 in our own homes and business. We have seen a large reduction in service calls. The Hart Family remains committed to providing the cleanest and most sustainable carbonless fuel of choice for our customers and neighbors.”

These benefits require little to no upfront capital investment unlike many other decarbonization options and provide immediate carbon reduction, not at some future time as other solutions promise.

Challenges and Future Prospects

While the transition to renewable liquid fuels presents numerous benefits, it is not without some minor challenges. Infrastructure updates, technician education and public awareness are hurdles that the industry must overcome. However, as technology advances and support grow, these challenges are becoming increasingly manageable. Technician education will play a vital role in this transition. Just as some were resistant to PEX and PVC replacing copper and cast-iron pipe or press technology replacing sweat, there will be those opposed to this future fuel.

Looking ahead, the future of the home heating oil industry seems destined for a renewable rebirth. Governments, businesses and individuals are recognizing the urgency of addressing climate change, and the home heating sector is a crucial battleground in this environmental struggle. In the pursuit of a greener warmth, the transition to renewable liquid fuels is not just an industry shift, it’s a collective effort to preserve the planet for generations to come.

As communities unite in this endeavor, the home heating oil industry, soon to be renewable liquid fuel industry, is proving that sustainable choices can keep us warm and comfortable while protecting the world we call home.

Robert O’Brien is Director of Education, National Oilheat Research Alliance (NORA).

Our good friend Mike Prencavage Jr., owner of The Family Plumber, Los Alamitos, Calif., and president of PHCC CA-ORSB, and some of his California PHCC constituents, recently took a tour of SoCalGas’s [H2] Innovation Experience and new model net zero home. “We were fortunate to visit the SoCalGas facility in Downey, Calif., more specifically a Read more

Our good friend Mike Prencavage Jr., owner of The Family Plumber, Los Alamitos, Calif., and president of PHCC CA-ORSB, and some of his California PHCC constituents, recently took a tour of SoCalGas’s [H2] Innovation Experience and new model net zero home.

![sustainability, hydrogen fuel technology, renewable energy, SoCalGas’s [H2] Innovation Experience, SoCalGas, heating, cooling, HVAC, plumbing](https://hydronicshub.com/wp-content/uploads/sites/2/2023/08/PHCC-Socal-Tour-78-610x407.jpg)

“We were fortunate to visit the SoCalGas facility in Downey, Calif., more specifically a mockup home that runs off a mix of hydrogen and natural gas. The system is a H2 microgrid; it’s a regenerative system that can operate solely based off a small amount of water input from either a city source or from a desalinized source, or ocean water,” says Prencavage Jr.

![sustainability, hydrogen fuel technology, renewable energy, SoCalGas’s [H2] Innovation Experience, SoCalGas, heating, cooling, HVAC, plumbing](https://hydronicshub.com/wp-content/uploads/sites/2/2023/08/PHCC-Socal-Tour-7-610x407.jpg)

The Innovation Experience is North America’s first-ever clean hydrogen powered microgrid and home. This project demonstrates how carbon-free gas made from renewable electricity can be used in pure form or as a blend to fuel energy systems and communities of the future.

Part of the Experience features clean hydrogen production and storage along with a nearly 2,000 square-foot home that can draw power from solar panels and convert excess renewable energy into clean hydrogen. “Simply put, the net zero home is using solar energy through PV panels, which is then stored in batteries—that’s for the electricity to actually power the home. Then, through an electrolysis method, running the electricity from the battery through water, they are creating hydrogen, which gets stored in a tank which then gets used to mix with the natural gas in the home so that it reduces your natural gas intake from the city by 20 percent,” says Prencavage Jr.

![sustainability, hydrogen fuel technology, renewable energy, SoCalGas’s [H2] Innovation Experience, SoCalGas, heating, cooling, HVAC, plumbing](https://hydronicshub.com/wp-content/uploads/sites/2/2023/08/PHCC-Socal-Tour-18-610x407.jpg)

SoCalGas has made a considerable, multi-million-dollar investment in what they believe is the future of clean renewable energy. “It is truly amazing how technology has gotten to this point for renewables. As the argument has always been we’re switching to electricity—here is California, it has been a huge push—most Californians understand, we just don’t have the infrastructure for this … so this visit opened a lot of minds to an alternative-type fuel source when it comes to a blended mix of hydrogen and natural gas,” says Prencavage Jr.

Listen to more on the SoCalGas visit by listening to the Appetite for Construction podcast here:

Uponor North America (Uponor) announced Anna Picchetti as the new Vice President of Marketing & Strategy, effective May 8, 2023. In her role, Anna will oversee Channel Marketing, Portfolio, Analytics, Sustainability, Segment, Engagement, Brand, and Communications. She will report to Uponor North America President Andres Caballero and be a key member of the company’s Senior Management Committee. Anna joins Read more

Uponor North America (Uponor) announced Anna Picchetti as the new Vice President of Marketing & Strategy, effective May 8, 2023. In her role, Anna will oversee Channel Marketing, Portfolio, Analytics, Sustainability, Segment, Engagement, Brand, and Communications. She will report to Uponor North America President Andres Caballero and be a key member of the company’s Senior Management Committee.

Anna joins Uponor with 20 years of experience in Marketing and Operations across industrial, technology, and medical device industries. She brings a wealth of experience developing forward-thinking strategies with a strong track record of execution at industry-leading brands such as Tennant, SPS Commerce, and Honeywell. She has worked at the forefront of innovations like autonomous vehicles and renewable energy, managed high-growth SaaS products and positioning, and transformed customer experiences.

“To help us move our business and aggressive growth goals forward, it was important we found a senior leader who can lead market disruption and drive innovation and segment growth initiatives all while guiding channel development, portfolio management, and go-to-market strategies,” says Caballero. “I’m confident Anna’s approachable leadership style will be a good cultural fit, as she has a proven track record of engaging teams by intentionally listening, learning, and setting clear expectations and outcomes.”

Anna earned a Master of Business Administration degree from the Carlson School of Management at the University of Minnesota. She is a member of the Women United Committee for the Greater Twin Cities United Way chapter and is also a member of Chief, a network for women in the C-Suite as well as senior executives and vice presidents. In addition, she is a USA Hockey-certified coach with a local youth hockey program.

For information about Uponor products, systems, services, and solutions, visit uponor.com.