Complex hydronic systems are so 2008, at least according to Mechanical-Hub ProStaffer Andy Mickelson, who owns Mickelson Plumbing and Heating in Missoula, Mont. His three-man shop does plenty of high-end residential work, and even here—no—especially here, their recipe for success, serviceability and efficiency includes a heavy dose of “keep it simple.” On a custom home Read more

Taco

Complex hydronic systems are so 2008, at least according to Mechanical-Hub ProStaffer Andy Mickelson, who owns Mickelson Plumbing and Heating in Missoula, Mont. His three-man shop does plenty of high-end residential work, and even here—no—especially here, their recipe for success, serviceability and efficiency includes a heavy dose of “keep it simple.”

On a custom home, where some contractors may be tempted to stack the material list high and deep, Andy does the opposite. He takes a step back from the blueprints and figures out how to use the fewest components needed without any compromise. Numerous zones, DHW production, multiple supply temperatures and snowmelt loops can and are all handled without making things more complicated.

“There are a number of things you can do to keep systems simple,” said Mickelson. “I make sure to avoid ‘inadvertent’ redundancy: that is, two products that accomplish the same task.

Proper sizing of radiation, pipe, pumps and boilers accurately is obviously important, too. Picking a control system that accomplishes what you need and nothing more is helpful.

Another thing we began doing a few years ago—and have noticed an improvement since – is sizing and grouping our zones to the capacity of a specific pump, instead for creating a zone with no real parameters, and trying to find a pump that fits the zone or zone group.”

Like a round peg in a round hole, selecting your circulator first can save a lot of trouble, as well as the issues that come with over- or under-pumping a system.

Starting in late October of last year, Mickelson was hired for a job that would test his ability to “keep it simple.”

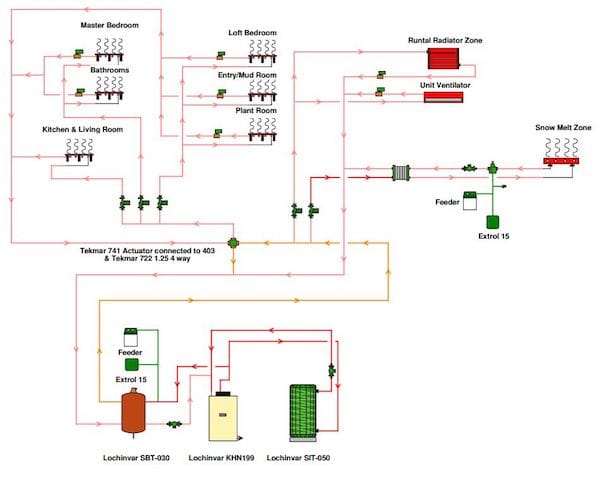

Mickelson’s work included installation of a mod-con boiler, seven zones of in-floor radiant, a hydronic unit ventilator, high-temp baseboard and 400 sq.-ft. of snowmelt.

Just out of town, the customer had purchased a nice lot with an older, 800-sq.-ft. home. The house was leveled and the basement foundation was re-used. The plan was to build a new 5,000-sq.-ft., two-story home on top of and around the original foundation.

Pick the pump first

“Like we do on all our jobs, I interviewed the homeowner long before we started the work, in order to really understand what they wanted,” said Mickelson. “Comfort was paramount, and budget not as much. So a thin concrete slab covers all radiant tubing, which is set at nine-inch centers.”

Before Mickelson started his loop layouts, he chose the Taco VT2218 variable speed circulator to serve all of the zones, with a total of six pumps. Additionally, Taco 007e single-speed ECM circulators are used on the 200 MBH fire-tube boiler and the indirect water heater.

“I like a Delta-T pump on a job like this, but another reason I used the VT2218 is for its broad pump curve, and we made use of it,” explained Mickelson. “It’s also very easy to program. Each radiant pump serves a group of zones. The zones are paired up according to the pump’s capacity, in terms of both head loss and flow rate. That way there aren’t any extra, underutilized circulators.”

Once the pump has been selected and the heat loss has been completed, the zones can be designed to fit the home. A common misconception about radiant circuits is that they must be as close to 300 feet long as possible, this just isn’t true. By dropping the length of each circuit, the head loss can be comfortably managed. The downfall to this is that the zone may require more circuits, but honestly the difference between five circuits and seven is minimal. It’s the same amount of tubing, no real noticeable increase in labor, just a larger manifold and a manageable head loss.

Low temp

Through zone valves, each pump supplies the appropriate amount of water and heat to a Watts Radiant stainless steel manifold, located remotely. Half-inch Watts RadiantPERT tubing was laid out before the gypcrete was poured.

“We chose the PERT instead of PEX because the radiant work was done throughout the winter. With spells of sub-zero weather, the increased flexibility of PERT was a huge benefit, especially considering our tight tube spacing.”

Because of the hydronic radiators, unit ventilator and snowmelt, the boiler maintains the buffer tank at 140°F at an outdoor design condition of -15°F. To make low temp water for the radiant zones, a Watts 4-way mixing valve with a tekmar 741 actuating motor was used. The 741 communicates with a tekmar 402 House Control in order to supply the exact radiant temperature need based on the outdoor temperature.

“The mixing valve sets the final delivery temp to all the low-temp zones,” said Mickleson. “It’s one of three elements at play here that really allow us to provide the exact temperature and flow rate to the radiant zones, so we’re really capitalizing on the primary/secondary piping, and squeezing every last ounce of comfort and efficiency out of the system. The other two elements are the outdoor reset on the higher temp boiler zones, and the variable-speed, Delta-T pumps. They all work hand in hand.”

The home has several areas with structural elements which made installing some of the tubing a challenging. Because of this, Mickelson had no choice but to run PEX supply and return piping through exterior walls. As a guard against the challenge of Montana winters, he wanted to run a glycol solution in the system. He installed a Neutra-Safe system feeder, which is an all-in-one reservoir, pump and control.

The home has several areas with structural elements which made installing some of the tubing a challenging. Because of this, Mickelson had no choice but to run PEX supply and return piping through exterior walls. As a guard against the challenge of Montana winters, he wanted to run a glycol solution in the system. He installed a Neutra-Safe system feeder, which is an all-in-one reservoir, pump and control.

High temp

The fourth and fifth VT2218 circulators serve the home’s three high-temp zones directly out of the buffer tank. In the basement, where the existing, uninsulated slab is still in place, Runtal baseboard was used in lieu of radiant tubing. Mickelson had considered ceiling radiant, but there wasn’t enough height to allow it. The circulator used for the baseboard zone also supplies water to the 12,000 BTU Smith Environmental unit ventilator in the garage attic.

The last variable-speed circulator serves as the snow melt system pump on the loop side of the brazed-plate heat exchanger. Mickelson uses a tekmar 654 Snowmelt Control to manage automatic operation and maintain a 25°F Delta-T across the 400 square-foot zone. This control features a snow and ice sensor that’s set in concrete when poured. The snowmelt loops also utilize a second Neutra-Safe System Feeder.

“Because of the components used and a thoughtful design, we’re covering five different loads with one boiler while installing it in a relatively tight space, all without being overly complicated,” said Mickelson.

Each pump supplies the appropriate amount of water and heat to a Watts Radiant stainless steel manifold.

“In the case of an emergency, I only have to deal with a single control system or one replacement pump,” he added. And with all that said, I can’t think of a quieter, more comfortable, or higher efficiency heating system.”

Mickelson is now going over a punch list, and looking forward to the feedback from the customer. He’s expecting rave reviews about the comfort level, and complete satisfaction when the owner receives their first propane bill.

Keith and Jenessa Frey’s dream took form in a 3,000-sq.-ft., three bedroom log home—located in Lancaster, Pa.—with space for two additional bedrooms. Jenessa’s kitchen occupies one end of the large open area on the main floor, blending easily into the great room with a tall stone fireplace. Heating and cooling equipment were much smaller than Read more

Keith and Jenessa Frey’s dream took form in a 3,000-sq.-ft., three bedroom log home—located in Lancaster, Pa.—with space for two additional bedrooms. Jenessa’s kitchen occupies one end of the large open area on the main floor, blending easily into the great room with a tall stone fireplace.

Heating and cooling equipment were much smaller than the Freys expected because of their insistence on heavy insulation. “That meant less cost to buy the HVAC gear and also a lot less energy to operate the equipment,” said Keith Frey. “I grew up in a drafty ol’ farmhouse; we learned that a dollar spent on insulation goes a long way.”

Piped dream

“Our mechanical contractor was impressed by the volume of equipment and material we could source through a single company purchased through wholesalers near here,” he added. So he and Kurt Shreiner, co-owner of Lancaster County-based Mountain View Heating & Cooling, LLC, chosen by the Freys to do most of the mechanical system installations, tapped Watts for a wide range of material and equipment.

Mountain View technicians installed 1,900 lineal feet of ½-inch Watts PEX radiant heat tubing in the lower concrete slab and 3,160 feet of 3/8-inch Onix synthetic rubber tubing for the under-floor areas in a five-zone system that would warm most of the home’s floors. They also hung three, prefabricated, pre-engineered Watts Hydronex panels to manage hydronic system flow.

Mountain View technicians installed 1,900 lineal feet of ½-inch Watts PEX radiant heat tubing in the lower concrete slab and 3,160 feet of 3/8-inch Onix synthetic rubber tubing for the under-floor areas in a five-zone system that would warm most of the home’s floors. They also hung three, prefabricated, pre-engineered Watts Hydronex panels to manage hydronic system flow.

Meanwhile, the Frey’s excavator trenched the geoexchange field behind the house. Four, 300-foot long trenches were dug to a depth of 10 feet and were piped as they were completed—each line feeding into a large manifold pit.

Mechanical systems, connected

Within a single day, as the excavator completed trenching, Keith Frey and Shreiner fused the geo-exchanged pipe.

Kevin Hul, Mountain View technician, made many of the connections inside the home, completing fluid circuits to and from the five-ton, water-to-air geothermal unit.

According to Shreiner, the heat pump was a perfect match for the tekmar controls chosen to integrate management of the home’s forced air geothermal heating and cooling equipment, and the five-zone radiant heat system.

According to Shreiner, the heat pump was a perfect match for the tekmar controls chosen to integrate management of the home’s forced air geothermal heating and cooling equipment, and the five-zone radiant heat system.

“The geo system allowed easy integration to the tekmar 557 thermostats and controls,” said Roger Prevost, hydronics general manager for Millersville, MD-based ROI Marketing, a manufacturer’s rep firm. “The controls included two 557 t-stats; five 552 t-stats and a setpoint and wiring center.”

“The tekmar controls are key components of the Hydronex panels,” said Watts Eastern Regional Manager Rich McNally. “Installers simply hang ‘em, make connections, add power and water.” The preassembled, pre-engineered panels are factory wired and tested. The three modular Hydronex panels, ready for off-the-shelf delivery, were ordered by Mountain View a few weeks before they arrived.

The first, primary panel moves hot water from the boiler-fed buffer tank; it includes outdoor sensors and interior thermostats. Injection panels two and three parcel-out heated supply to feed the home’s different-temp radiant heat zones. Taco zone controls govern a bevy of Taco pumps, mounted at a 45-degree angle on the panels to control flow within the mile-long network radiant tubing.

All the comforts of home

Shreiner chose a 125 MBH, wall-hung Laars LX mod-con boiler as the main source of heat for the home. “I especially like the system for its high efficiency [95% AFUE] and that the New Hampshire company makes the boiler here in the US, even their own stainless steel heat exchangers. It’s got an advanced control system and outdoor reset, a condensate trap, zero clearance installation and allows venting up to 150 feet,” said Shreiner. “And it’s so danged quiet.”

He added that the boiler is paired with two 120-gallon Bradford White tanks, one of which had a large stainless steel coil inside. “We chose these for their very low standby loss,” added Shreiner. “One of them is a buffer tank for the hydronic system. The hydronic panels pull from this large volume of water to meet the home’s space heating needs. The other tank is an indirect water heater with a large stainless steel coil inside to heat domestic water.

He added that the boiler is paired with two 120-gallon Bradford White tanks, one of which had a large stainless steel coil inside. “We chose these for their very low standby loss,” added Shreiner. “One of them is a buffer tank for the hydronic system. The hydronic panels pull from this large volume of water to meet the home’s space heating needs. The other tank is an indirect water heater with a large stainless steel coil inside to heat domestic water.

“The buffer tank is kept at temperatures between 110 and 140 [°F] is the first task met by the boiler; temperatures in the tank vary according to ambient temps as monitored by the outdoor reset control,” Shreiner continued. “The hydronic panels pull from this large volume of water to meet the home’s heat needs. The other tank is an indirect water heater in the truest sense, for domestic water.”

Populating the Hydronex control panels and managing flow for all of the home’s five radiant heat zones are Taco 0015, 3-speed circulators. The circs also control flow to and from both of the indirect water heaters. A Taco 4900 air separator posts quality control guard duty for the entire hydronic system. Taco zone controls interface easily with the tekmar components.

“We’ve installed Taco circs, pumps, zone valves and zone controls for years,” added Shreiner. “With a system as robust as this one, there was no way we’d use anything but the products we’ve come to trust.”

“We’ve installed Taco circs, pumps, zone valves and zone controls for years,” added Shreiner. “With a system as robust as this one, there was no way we’d use anything but the products we’ve come to trust.”

The Freys also installed a small HeatWeave electric radiant mat below the tile in their guest bathroom—complete with its own programmable thermostat. “I didn’t want my guests to experience cold feet here. It was a very small splurge,” said Jenessa Frey.

Water quality, assured

The Freys have a good, on-site well. But – common to many agricultural areas – coliform bacteria and nitrates are present. After testing for water-borne minerals, sediment and other contaminants, it was clear to the Freys they’d need water treatment systems.

Well water now passes through a sediment filter; it then flows through a Watts ultraviolet unit to kill bacteria. Water then moves through a Watts Pure Water non-chemical iron removal system. Domestic water then makes its way through a Watts OneFlow scale prevention system to control water hardness; the system’s scale media operates catalytically without salt or chemicals, and doesn’t produce wastewater.

Well water now passes through a sediment filter; it then flows through a Watts ultraviolet unit to kill bacteria. Water then moves through a Watts Pure Water non-chemical iron removal system. Domestic water then makes its way through a Watts OneFlow scale prevention system to control water hardness; the system’s scale media operates catalytically without salt or chemicals, and doesn’t produce wastewater.

“It doesn’t even require electricity,” said an amazed Matt Woodcraft, president of Lifeflow Plumbing, who installed the water treatment, filtration and plumbing systems.

“The scale prevention is effective at preventing over 98 percent of the scale produced by the hard water,” said Woodcraft. “The only maintenance required on the system is a simple media replacement after three years of service.”

The final water treatment happens in Jenessa’s kitchen where Woodcraft installed an under-sink reverse osmosis system by Watts.

“You might say the Freys took on a challenge or two in solving the problems they encountered with the groundwater,” added Woodcraft. “But we learned quickly that there’s a solution for every variety of need.”

A Taco hot water recirculation system and dedicated return line were installed to continuously circulate hot water to showers and fixtures.

Delayed gratification

Within a few months, the Frey’s excavated trenches were invisible, covered by a robust crop of soybeans. The field now serves two purposes with equal vigor: farmland, and geothermal exchange. Fall came and the soybeans were harvested and sold. The geothermal system switched between cooling to heating modes effortlessly while harvesting subterranean BTUs.

“Being my own GC added substantial time to complete the home,” said Keith Frey. “But, we saved a bundle, most of which allowed us to improve the home’s carbon footprint.

“Being my own GC added substantial time to complete the home,” said Keith Frey. “But, we saved a bundle, most of which allowed us to improve the home’s carbon footprint.

“The geothermal, radiant heat systems and water quality equipment are facets of the home we’re most proud of,” he added.

Check out what we’ve got coming up in the next episode of the Mechanical Hub Onsite Video Series: Montana https://youtu.be/jdQg8uIx73U Read more

Check out what we’ve got coming up in the next episode of the Mechanical Hub Onsite Video Series: Montana

Taco Comfort Solutions is proud to announce Robert Bean as the 2017 recipient of the Dan Holohan Lifetime Contribution to Comfort Award. The award was presented on Monday, January 30 at the AHR 2017 Show in Las Vegas. The Dan Holohan Lifetime Contribution to Comfort Award is given annually to an HVAC professional or company Read more

Taco Comfort Solutions is proud to announce Robert Bean as the 2017 recipient of the Dan Holohan Lifetime Contribution to Comfort Award. The award was presented on Monday, January 30 at the AHR 2017 Show in Las Vegas.

The Dan Holohan Lifetime Contribution to Comfort Award is given annually to an HVAC professional or company that has made a substantial contribution to comfort technology, advancement, or training while displaying the exceptional good humor and love of people exhibited by Dan Holohan throughout his career. Without a doubt, Robert displays these characteristics and is a steadfast advocate of the industry.

Robert Bean (r), accepts the Dan Holohan Lifetime Contribution to Comfort Award from Taco CEO Wil VandeWiel (l) and Taco Chairman of the Board, John White, Jr.

“This award is for someone who Taco has found to be influential in our industry,” said Taco’s Executive Chairman of the Board, John Hazen White, Jr. “Robert Bean is tremendously committed to forwarding the hydronic business.”

Robert has been a leading voice in residential and commercial comfort and efficiency for nearly 40 years. He is the director of Indoor Climate Consultants, Inc., based in Calgary, Alberta. He also manages HealthyHeating.com, a volunteer-based, not for profit, on-line educational resource – serving as a technical interpreter and consolidator of academic research done within the building and health sciences.

Through his writing and speaking about the need to design comfort systems for people – not buildings – Robert has led the way to change how industry experts view the concept of comfort, and this has helped to improve comfort technology. A proponent of hydronic heating and cooling, the stated purpose of his website, HealthyHeating.com, is “to offer a research-based site for self-study on topics bridging the health and building sciences; and to promote the benefits of radiant-based HVAC systems with dedicated outdoor air systems as energy efficient solutions to indoor environmental quality challenges.”

Robert is a graduate of the Building Construction Engineering Technology program from the Northern Alberta Institute of Technology, a Registered Engineering Technologist holding membership with the Association of Science and Engineering Technology Professionals of Alberta, and a Professional Licensee in Mechanical Engineering holding membership with the Association of Professional Engineers, Geologists and Geophysicists of Alberta. In addition to his training and professional practice in building construction engineering technology and HVAC engineering, he is a graduate of the Alberta School of Drafting (AutoCad) and The University of Calgary, Business Owner Transition Program.

That’s not the name of a southern rock band, but it could be. It would also make a great name for a project that Kelleher Heating and Cooling took on recently, just outside of Richmond, Va. Dating back to the 1700s, the historic Brook Hill estate has been home to dozens of Virginia dignitaries, and Read more

That’s not the name of a southern rock band, but it could be.

It would also make a great name for a project that Kelleher Heating and Cooling took on recently, just outside of Richmond, Va.

Dating back to the 1700s, the historic Brook Hill estate has been home to dozens of Virginia dignitaries, and has always been under the careful watch of a family descendant.

The 11,000-sq.-ft. plantation home, built in 1850, served as a Confederate field hospital. The basement was the final resting place of several slaves, and Route 1 used to run directly through the property.

It sounds a bit spooky, and looks the part, too. But despite the gothic mansion’s towering profile and dark colors, its sole inhabitant swears that the only frightening occurrence in recent years has been the arrival of the oil bill.

In heating season, the drafty old mansion generally consumed 1,000 gallons of fuel oil each month. Rated at 5 GPH each, two old boilers heat the home. One of the boilers had just recently sprung a leak, too.

From l to r: Cory Sandlin, apprentice plumber, Dennis Shiflett, master plumber, Lonnie Herman, master plumber, Peter Grainger, plumbing sales (master plumber), Tom Crampton, master plumber, Chuck Greenberg, plumbing, A/C and electrical supervisor.

While the drivers at Kelleher Heating and Cooling were happy to deliver the #2, Pete Grainger, estimator at the 40-person company, had suggested for years to retrofit with a natural gas system. After two rough winters in a row, the estate took him up on it in 2015.

System design began in the spring. The plan was to change the living space as little as possible; just add new T-stats. A dozen or more fireplaces were the original source of heat. Sometime in the past half-century, hydronic wall registers, fin-tube baseboard and a little cast iron had been added to create two big zones.

Trading high mass for low mass

The Kelleher crew went into demolition mode in late August. Lonnie Herman, who’s been with Kelleher for 20 of its 50 years, was lead installer on the job. He was joined by Dennis Shiflett, Tom Crampton, Chuck Greenberg and Cory Sandlin.

The oil tanks were hauled out and the two massive boilers were broken apart. One of the big units had recently developed a leak. At the same time, RE Michel delivered the two new, 95 percent efficient Burnham Alpine 399 boilers. The utility ran a gas line several hundred yards to the mansion, at which point Kelleher took over and continued for another 40 feet.

“The install was pretty straightforward,” continued Greenberg. “We piped and wired the boilers in a lead-lag configuration so that we have a 10-to-one turndown. The system can provide anywhere from 80,000 to nearly 800,000 BTUs. That’s a major asset here.”

But there was another big advantage to pairing condensing boilers with the old hydronic system: the two giant zones made for big temperature differentials and long condensing cycles. Generally, the downside to a big Delta T on a fin-tube system is a slight temperature variation across the different rooms on any given zone. But most of the mansion is uninhabited, so slight temperature variance is of little concern.

But there was another big advantage to pairing condensing boilers with the old hydronic system: the two giant zones made for big temperature differentials and long condensing cycles. Generally, the downside to a big Delta T on a fin-tube system is a slight temperature variation across the different rooms on any given zone. But most of the mansion is uninhabited, so slight temperature variance is of little concern.

Given then old piping and radiation throughout the house, three Y-strainers were included on the new piping. The only real challenge was venting. The Kelleher techs ran pipe 35 feet to reach a suitable area. The thick stone and brick foundation took a while to break, though. The job wrapped up about two weeks after it began.

Lots of improvements

“This was only the second time I’ve installed an Alpine,” said Greenberg. “We’ve used Burnham’s cast-iron boilers for decades, and I really wanted to try the Alpine in a dual-boiler setup. The controls are friendlier than what we’re used to on a condensing boiler, and the support was fantastic.”

Throughout the project, Kelleher worked with Ron Beck at US Boiler Company, RE Michel Company, and Cindy Lau at ROI Marketing if a question came up.

With all that new stainless steel in the basement, it would’ve been a shame not to get rid of the old LP-fired, 80-gallon water heater. Kelleher installed a 50-gallon Burnham Alliance indirect tank as a third zone off the main loop.

“Most folks have no concept of what it takes to keep a place like this this intact,” said the anonymous caretaker with a smile in her voice. “With the new heating system, it’ll be a little bit easier.”

Components:

Two Alpine 399

Alliance 50-gallon

Taco Zone Controller

Taco 0014-30 Circulators

2″ Spirovent Air Separator

Two 1 1/2″ Strainers, One 2″ Strainer (Legend)

Amtrol SX-90 Expansion

Amtrol ST12 Potable Expansion

Maxitrol Regulators with Vent Limitera

4″ CPVC Vent Pipe

Zoned with 0014 Circulators and Check Valves

Standard Outdoor Reset