… what is the level of scale in your water? Hard to say, I’d imagine. But, over time, believe me, you’ll know. Scale, also known as limescale, refers to mineral buildup—primarily magnesium and calcium—that creates a white, chalky-like substance that can accumulate on the plumbing system’s internal components, including water heaters, pipes, and fixtures, says Read more

tankless

… what is the level of scale in your water? Hard to say, I’d imagine. But, over time, believe me, you’ll know. Scale, also known as limescale, refers to mineral buildup—primarily magnesium and calcium—that creates a white, chalky-like substance that can accumulate on the plumbing system’s internal components, including water heaters, pipes, and fixtures, says Randall Oshiro, Lead Engineer, Noritz America.

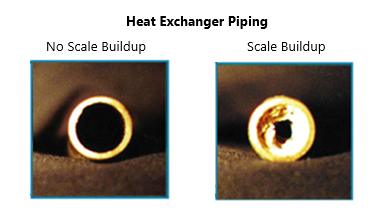

In other words, “Common in household water, especially in areas with hard water, scale is essentially the crusty stuff you sometimes see on old pipes or the heating element of an old kettle,” says Ben Tate, National Sales Manager—Water Treatment, Navien, Inc. “When water is heated, these minerals crystallize and stick to surfaces such as the interiors of pipes, boilers, and heaters, forming a hard, insulating layer. It’s a natural process, but not exactly a welcome one, as it hampers the efficiency of any appliance it settles in.”

Scale’s Geography

Scale’s prevalence comes down to the geological makeup of the land through which your water travels. Water is a universal solvent, and as it moves through soil and rock, it picks up minerals like calcium and magnesium. In areas rich in limestone and other calcareous rocks, which are composed mainly of calcium carbonate, water tends to carry a higher load of these minerals. Consequently, regions with such geological features—think of areas like Texas and Florida—often struggle more with hard water and, by extension, scale.

Calcium and magnesium are naturally occurring minerals, says Oshiro. Depending on where the water is drawn from, water flowing through ground sources that contain high concentrations of these minerals will absorb some of the minerals. For example, water drawn from an aquifer with a high concentration of limestone will inevitably have a high concentration of lime (calcium). Like the previous example, areas where water is drawn from underground are often where the highest concentration of hard water exists.

A Water Heater’s Nemesis

Yet the “damage” scale can bring can’t be overstated, says Dan Giosia, Assistant Product Manager, Bradford White Corporation, “The accumulation of scale in a water heating system diminishes the overall performance, efficiency, and lifespan of the water heater unless preventative maintenance measures are implemented.”

Scale poses a triple threat to water heating systems, says Tate. First, it’s an insulator. In a domain where efficient heat transfer is key, scale is a formidable barrier that keeps heat from doing its job effectively, which can drive up energy costs as your system struggles to keep up. Second, scale buildup increases the pressure in water lines and heating chambers, which can lead to leaks or mechanical failures. Lastly, the more energy and repairs a system requires, the more its lifespan diminishes. That’s why preventing scale isn’t just about maintaining water flow; it’s about saving money and extending the life of your equipment.

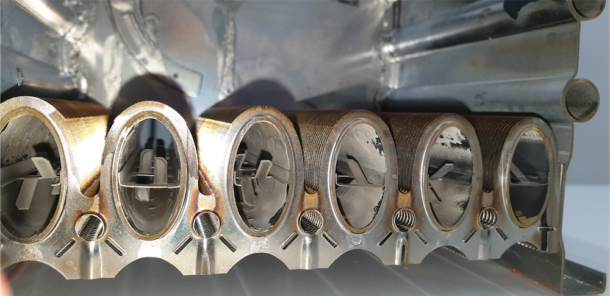

According to Oshiro, the primary danger of this scale formation is that it can accumulate inside the water heater (on the heat exchanger of tankless water heaters, along electrical heating elements, or along the internal flue of gas storage water heaters). This scale formation acts as an insulator in large amounts, preventing the proper heat exchange between the water and the heating source. “When this happens, the temperature will increase—as heat is not being drawn away at the designed rate—leading to increased thermal stress and decreased longevity of the internal components. Additionally, this buildup can reduce the surface area of piping, which can reduce the flow performance of the fixtures as well,” says Oshiro.

Tankless Magnified

Scale impacts both tank-type and tankless water heaters, though it manifests differently in each system, says Tate. In tank-type heaters, scale settles at the bottom of the tank, reducing heat transfer efficiency and leading to increased energy consumption and potential corrosion. Over time, this can significantly shorten the lifespan of the heater. Conversely, tankless models, which heat water directly, experience scale buildup directly on their heat exchangers. This can decrease heating efficiency and disrupt water flow, though it does not necessarily indicate a greater susceptibility to scale than tank-type heaters.

Regardless of the system type, the key to mitigating scale effects lies in regular maintenance. Both tank-type and tankless water heaters benefit from routine descaling and the proactive use of water treatment solutions like water softeners or scale inhibitors. Properly maintained, both systems can handle scale effectively, ensuring efficient operation and extending the lifespan of the heater. Thus, neither system is disadvantaged by scale when properly cared for, allowing users to choose based on their specific needs and preferences.

The reality is the mechanism/issue is about the same for both types of technology. “However, it will present itself much sooner/more apparently with a tankless type water heater than a tank-type water heater. The reason for this is basically that the pipes are smaller. Imagine a ¾” pipe and 24” round storage vessel. The smaller pipe, with a ¼” of scale buildup, loses significantly more of its surface area in comparison. This means that issues like reduced flow will become more apparent sooner,” says Oshiro.

However, it should be noted, continues Oshiro, that this same amount of scale will have the same actual effect on the systems (reduced efficiency, higher thermal stress). As a result, a tankless water heater may show signs of decreased performance sooner; however, this also allows the customer to preemptively conduct maintenance to ensure that the product will last many times longer than a storage tank-type water heater.

The storage tank-type water heater often continues to build up this scale over time, resulting in lower efficiencies (meaning higher operating costs) and eventual failure sooner. This scale formation is one of the primary mechanisms by which water heaters will fail. 1

According to Bradford White’s Giosia, scale does pose a greater issue for tankless water heaters compared to tank-type water heaters due to their compact heat exchanger design. With a limited surface area and brief heating period, tankless heaters must rapidly elevate water temperatures, requiring high temperatures within the heat exchanger. As a result, scale tends to accumulate on this surface. If scale buildup becomes excessive, it can restrict water flow through the heat exchanger to the point of causing component or unit failure so it’s important for homeowners to contact their plumbing professional for regular maintenance.

In comparison to gas tank-type water heaters, electric tank-type heaters are generally more susceptible to scale buildup. This is primarily due to the very hot surfaces of electric heating elements, which have a small area and are prone to accumulating limescale within the tank. However, the impact of scale buildup is limited by the fact that electric heating elements are relatively inexpensive to replace, especially when compared to the cost of replacing a tankless gas heat exchanger or complete unit.

Gas tank-type water heaters may vary in susceptibility to scale buildup depending on their design. Units with a burner located outside the tank are typically less affected by scale compared to those with an internal heat exchanger where scale can accumulate.

Action Plan

What can contractors/homeowners do to “combat” scale? “The first step is to know your water supply,” says Oshiro. “Almost every municipal water supply company will annually publish a water quality report that will include data about the hardness of your water supply. This rating will often be rated on a scale of grains per gallon (gpg), parts per million (ppm), or milligrams per liter (mg/L). These ratings tell the density of mineral hardness (calcium) present in the water supply. The USGS[1] has a relative hardness indicator, where 61-120 mg/L (3.6-6 gpg) would be considered somewhat hard water.”

The best way to reduce scale is to treat the cause. This means using water treatment devices to prevent the calcium from building up in your water heater and piping. However, this isn’t always possible, so maintenance can be conducted by a descale flush: running a deliming agent (ex., vinegar or a specialized deliming agent) solution through piping the water heater to neutralize the calcium. As calcium is a basic material (pH >7), the acidic deliming agent will neutralize the calcium and remove buildup.

It’s also essential to adhere to the manufacturer’s recommendations for preventative maintenance, including specific procedures and frequency, for their product, advises Giosia.

Regular descaling of the water heater is often recommended to minimize scale buildup on the heat exchanger of a tankless water heater. The frequency of preventative maintenance typically depends on the characteristics of the water supply in your area, such as whether it is heating hard or soft water.

Installing a water softener can help reduce the hardness of the incoming water into both tankless and tank-type water heaters. However, it’s important to consult with a plumbing professional to ensure compatibility and to follow their recommendations.

Navien’s Tate says contractors and homeowners in these regions should adopt a proactive approach to water treatment. Installing a water softener is one effective strategy; it replaces hardness ions like calcium and magnesium with sodium or potassium, preventing them from forming scale. Additionally, I’d recommend considering scale prevention systems, which are designed to transform hardness minerals into harmless crystals that won’t stick to surfaces. Regular maintenance checks are also vital—they help ensure that any potential scale buildup is managed before it becomes a serious issue.

If you know that your water source is hard water, Oshiro suggests that you can take action to alleviate the risks.

- Develop a routine maintenance plan: This can be done by “descaling,” or flushing, your water heater regularly, depending on usage and quality. Asking your water heater manufacturer or installer for recommendations on frequency is a great first step.

- Treat the water: There are ways to eliminate (sequester or remove) hard-water minerals from the water source. These include items like water softeners, which use an ion-exchange process to physically remove free calcium from the water, or products that use a polyphosphate media to sequester the calcium to prevent it from coming out of the solution when heated.

Technology Tips

Is there newer technology that could make the equipment more scale-resistant? “Indeed,” says Tate. “One of the latest advancements in this area is Template Assisted Crystallization (TAC), which is a highly effective technology for preventing scale without the use of chemicals or salt. TAC systems work by transforming the calcium and magnesium minerals in hard water into stable, harmless crystal particles. These particles then flow through the system without sticking to surfaces, effectively preventing scale buildup. This technology is particularly useful for protecting high-efficiency tankless water heaters from scale, ensuring they operate at optimal efficiency while extending their lifespan.”

To some degree, says Oshiro, the selection of materials, design of the heat transfer surface, and the temperature in which the system operates, all have roles to play in controlling the amount of scale formation.

- Materials with less surface roughness provide less chance for scale particles to attach.

- Systems with lower temperature rises can also slightly reduce the formation rate of scale.

There is constant research into reducing the harmful effects of scale formation in water heating products, but at its core, it is a challenging situation to avoid entirely.

According to Giosia, some tankless water heater models incorporate technology aimed at enhancing scale resistance, such as scale reduction technology and replacement filtration cartridges. Moreover, water softeners can serve a similar purpose in mitigating scale buildup.

However, despite these advancements, maintenance remains essential for all tankless water heaters to prevent excessive scale accumulation. Regular upkeep is necessary to ensure optimal performance and longevity of the unit.

In conclusion, the timeline for significant damage can vary widely depending on the water’s hardness and the frequency of system maintenance. In regions with very hard water and minimal preventive measures, says Tate, significant scale buildup can occur within just a few months, leading to efficiency losses and potential system failures. Conversely, with proper management and regular maintenance, scale-related damage can often be staved off for years, preserving the efficiency and extending the life of the system.

1

https://www.usgs.gov/special-topics/water-science-school/science/hardness-water#:~:text=Measures%20of%20water%20hardness&text=General%20guidelines%20for%20classification%20of,mg%2FL%20as%20very%20hard

It’s that time of year again when people reflect on what they’re thankful for in the past year, and hope for a positive 2024. I cannot stress enough the job that Brent and Kathleen Ridley (@toolpros & @toolwife) do with Miracle Mechanical, a charitable organization dedicated to uplifting families in need, one at-no-cost-HVAC/plumbing repair at Read more

It’s that time of year again when people reflect on what they’re thankful for in the past year, and hope for a positive 2024. I cannot stress enough the job that Brent and Kathleen Ridley (@toolpros & @toolwife) do with Miracle Mechanical, a charitable organization dedicated to uplifting families in need, one at-no-cost-HVAC/plumbing repair at a time. “Honestly, it’s hard to put into words,” says Brent Ridley. “Seeing and feeling the gratitude from homeowners is an incredible feeling, and something that never gets old.”

It’s that time of year again when people reflect on what they’re thankful for in the past year, and hope for a positive 2024. I cannot stress enough the job that Brent and Kathleen Ridley (@toolpros & @toolwife) do with Miracle Mechanical, a charitable organization dedicated to uplifting families in need, one at-no-cost-HVAC/plumbing repair at a time. “Honestly, it’s hard to put into words,” says Brent Ridley. “Seeing and feeling the gratitude from homeowners is an incredible feeling, and something that never gets old.”

Tool Pros began as tool review brand, as the brand grew and relationships with tool manufacturers were made, Ridley felt a need to use his platform for more. “Free tools and trips are great but I thought to myself. ‘let’s actually do something that matters.’”

Combined with his platform and what he knew best—HVAC /plumbing—Miracle Mechanical was born. Shortly after the concept, Ridley reached out to his contacts at RIDGID to gauge interest. “Thankfully they loved the idea and wanted to sponsor the very first project. Two months later we completed our first project, and the rest is history,” says Ridley.

Officially, the primary facilitators of Miracle Mechanical consist of Brent and his wife Kathleen. They also bring in a production crew of three to four people, and their team of HVAC / plumbing contractors—usually a 4-man crew—for a project day.

Ridley says that the goal is always to complete as many projects as possible; however, they are averaging four to five projects per year. In fact, Miracle Mechanical just completed a project this past October with Sharkbite.

And they have partnered with RIDGID for the next project taking place in early 2024. In the past, Miracle has teamed up with the AHR Expo but nothing for 2024. “We look forward to partnering with AHR for their work force development program in the future,” says Ridley.

And they have partnered with RIDGID for the next project taking place in early 2024. In the past, Miracle has teamed up with the AHR Expo but nothing for 2024. “We look forward to partnering with AHR for their work force development program in the future,” says Ridley.

But between working as an HVAC contractor, content creator, Miracle Mechanical facilitator, podcaster and Lowe’s Santa, finding time to take a deep breath can be difficult. “Sure, it can feel overwhelming at times,” says Ridley. “Thankfully, I have my wife who is a full-time manager and coordinator for the Tool Pros brand and Miracle Mechanical. Her dedication to the brand allows me to focus on my HVAC/plumbing business (H & M Services, Inc.), as well as other creative outlets—without dropping any balls in the process.”

The Miracle Mechanical concept is such a good one, and one that I know Ridley hopes he can provide nationally. At this time, logistics and funding for national projects have been a huge obstacle, but one that I’m confident we’ll overcome in the next couple of years,” says Ridley.

More About Brent Ridley

Ridley started into the trades right out high school in 2004. His girlfriend’s father, at the time, owned an HVAC business, and he started the summer after senior year doing commercial duct work and hated it. It was only until he found service and repair that he fell in love with the HVAC industry. “From there, I have always strived to make it more than just a ‘Job,’ but a lifestyle. If you want to get ahead in life, you can’t clock out at 5 pm.”

In the earier days before social media, Ridley wrote long-form, trade-specific tool reviews on a site called HVACTalk.com, which no longer exists. In 2017, Ridley started his successful Tool Pros Podcast. “Not long after, the social media portion of the brand quickly outgrew the podcast, leading to many opportunities that I am very grateful for, like Miracle Mechanical,” says Ridley.

Stewart-Haas Racing’s Chase Briscoe along with Tony Stewart Racing’s Leah Pruett and Matt Hagan to Carry Rinnai Branding in 2023. Kannapolis, N.C. — Rinnai America Corporation has partnered with Tony Stewart and his racing entities in NASCAR and the NHRA to promote its line of products using his diverse motorsports portfolio. In NASCAR, fans will see the red Read more

Stewart-Haas Racing’s Chase Briscoe along with Tony Stewart Racing’s Leah Pruett and Matt Hagan to Carry Rinnai Branding in 2023.

Kannapolis, N.C. — Rinnai America Corporation has partnered with Tony Stewart and his racing entities in NASCAR and the NHRA to promote its line of products using his diverse motorsports portfolio.

In NASCAR, fans will see the red Rinnai logo in an associate position on Stewart-Haas Racing’s No. 14 Ford Mustang driven by Chase Briscoe in the NASCAR Cup Series. In the NHRA, Tony Stewart Racing drivers Leah Pruett and Matt Hagan will carry the Rinnai logo in the Camping World Drag Racing Series, with Pruett running a full Rinnai primary sponsorship on her Top Fuel dragster in two events – the NHRA Winternationals March 30-April 2 in Pomona, California, and the NHRA Carolina Nationals Sept. 22-24 in Charlotte, North Carolina. Hagan will sport a full Rinnai livery on his Funny Car in the NHRA New England Nationals June 2-4 in Epping, New Hampshire, an event the three-time champion has won four times, including in 2022.

“Our expertise in tankless water heating is unmatched, and this partnership with Tony Stewart and his NASCAR and NHRA teams allows us to tell that story in a thrilling, team-oriented environment that emulates the quality and dedication we put into our products and services,” said Frank Windsor, president, Rinnai America Corporation.

“The similarities of our business to racing are numerous especially when speed efficiency, and superior quality are keys to success. Performance is paramount, and that’s something Rinnai has always understood. It’s part of our overall commitment to our customers, and racing embodies that commitment.”

The NASCAR Cup Series encompasses a total of 39 events in its milestone 75th season, beginning with the non-points Busch Light Clash Feb. 5 at the Los Angeles Memorial Coliseum and ending with the season finale Nov. 5 at Phoenix Raceway. The NHRA Camping World Drag Racing Series includes 21 events in 2023. Its 72nd season starts with the NHRA Gatornationals March 9-12 in Gainesville, Florida, and concludes with the NHRA Finals Nov. 9-12 in Pomona.

“We’re incredibly proud to have this partnership with Rinnai because it shows the strength of our motorsports program,” Stewart said. “NASCAR and NHRA offer two very different fan experiences and combined they touch every corner of the country. Rinnai and its customers get the best of both worlds because our program allows a number of choices to promote its products and services.”

In addition to branding on racecars, Rinnai becomes the official tankless water heater of Stewart Haas Racing and Tony Stewart Racing. This designation highlights Rinnai’s brand promise of “Creating a healthier way of living®”, a mantra that is at the forefront of all the company’s efforts. By continuing to offer quality products and services to homeowners and organizations, Rinnai is aiding in providing businesses and homes with energy-efficient hot water options for cleaner and healthier living.

The announcement of the partnership comes after a series of milestone events for Rinnai America. “We opened a new manufacturing facility last year in Griffin, Georgia, that has allowed us to combat shipping delays and supply-chain challenges. In this facility, we manufacture our new RE Series™ Tankless Water Heater, the first and only non-condensing unit with a built-in pump. That product, along with our ability to manufacture in the United States, is another reason why we’ve partnered with Tony Stewart and have become the official tankless water heater of Stewart Haas Racing and Tony Stewart Racing,” Windsor said.

The Rinnai® BMS Gateway creates a unique solution for hot water management Having a way to control and monitor hot water usage creates efficiencies for business leaders and facility managers but is often critical to keeping businesses’ doors open. That’s why Rinnai has launched the Building Management System (BMS) Gateway, a new product that will provide commercial Read more

The Rinnai® BMS Gateway creates a unique solution for hot water management

Having a way to control and monitor hot water usage creates efficiencies for business leaders and facility managers but is often critical to keeping businesses’ doors open. That’s why Rinnai has launched the Building Management System (BMS) Gateway, a new product that will provide commercial and vertical markets a software system used to remotely control and monitor Rinnai Commercial Tankless Water Heaters.

“Our brand promise is Creating a Healthier Way of Living® and we are focused on providing simple, affordable solutions for businesses,” said Frank Windsor, President of Rinnai North America. “The Rinnai BMS Gateway is the next step to empowering customers to actively manage hot water and help it run seamlessly through any building.”

Whether using the optional Touch Screen User Interface that acts as an enhanced controller or working directly through the BMS Gateway, businesses can remotely turn tankless water heaters on or off, adjust water temperature, monitor flow rates, operation hours and more. The BMS Gateway and Touch Screen User Interface also allows up to 15 view-only parameters such as water flow rates, combustion cycles, operation hours and error code history.

Businesses can pair up to six Rinnai Commercial Condensing Water Heaters per BMS Gateway, with up to four gateways per network, for a maximum of 24 tankless units connected thereby enabling greater reach. Additionally, the BMS Gateway works with Rinnai CU199 and CU160 condensing tankless models and uses BACnet, Modbus or LonWorks communication protocols.

“Many commercial settings, such as school campuses, healthcare facilities, multifamily and government buildings, are often required to have BMS capabilities,” said Dale Schmitz, Rinnai Marketing Segment Manager. “We are now able to provide customers with an intuitive gateway to remotely control and monitor Rinnai Commercial Tankless Water Heaters through a customer-supplied BMS system.”

Businesses can upgrade their tankless water heaters to include the BMS Gateway or install a whole new system and save thousands in acquisition, maintenance and energy costs. Rinnai tankless units offer precise load tracking, so the amount of energy consumed is directly correlated to the amount of water heated at any given time versus having to heat and re-heat stored water with boilers and tanks.

The Rinnai Tankless Rack System comes in Wall-hanging or Freestanding configurations, includes factory assembled manifolds for gas and water that are tested and warrantied, provides built-in redundancy and can be combined with up to 24 units to provide 4.8 million Btu.

Rinnai is here to solve the needs of businesses while also providing easy, affordable turnkey solutions. With the latest and greatest addition of the BMS Gateway, Rinnai is here to keep hot water running for businesses to stay in business.

To learn more about Rinnai, visit www.rinnai.us.

The Smarter Way to Go Tankless The Infiniti™ K Series of tankless water heaters is the smarter way to go tankless. The Infiniti K uses STEADISET™ Technology to keep water temperature consistent and virtually eliminate “cold water sandwich” with NO internal buffer tank. It features SRT™ Scale Reduction Technology for better performance, longer operational life Read more

The Smarter Way to Go Tankless

The Smarter Way to Go Tankless

The Infiniti™ K Series of tankless water heaters is the smarter way to go tankless. The Infiniti K uses STEADISET™ Technology to keep water temperature consistent and virtually eliminate “cold water sandwich” with NO internal buffer tank. It features SRT™ Scale Reduction Technology for better performance, longer operational life, and lower maintenance costs versus conventional tankless. The series delivers efficiency up to .96 UEF, which helps maximize the financial benefits of choosing tankless.

Features include:

- Exceptional Temperature Stability.STEADISET™ Technology keeps the temperature consistent with NO internal buffer tank.

- Best-In-Class Venting Lengths. Vent with either 2” or 3” PVC or polypropylene.

- Best-In-Class Scale Reduction. SRT™ Scale Reduction Technology delivers improved performance, longer life and lower maintenance costs.

- Best-In-Class Modulation. 22:1 turndown.

- Best-In-Class Warranty.15 years (heat exchanger).

- Efficient Performance – Even at Low Flow Rates. Activates at just 0.45gpm.

- Easy Installation. Top connections and built-in flush ports reduce time and cost of installation. No combustion analyzer needed.

- Contractor-Friendly Design for Easy Field Maintenance – Built for the contractor to give you room to work.

https://youtu.be/aOrKiM5VhfE

For more information visit Bradford White Infiniti™ K Series.