U.S. Boiler Company recently hosted a Hops & Heat learning event at Trillium Brewing Company in Canton, MA. This is the second event of its kind U.S. Boiler Company has hosted in New England. Heating contractors attended the event to learn about high efficiency heating equipment, including the Ambient Air-to-Water Heat Pump, Citadel commercial condensing Read more

U.S. Boiler Company

U.S. Boiler Company recently hosted a Hops & Heat learning event at Trillium Brewing Company in Canton, MA. This is the second event of its kind U.S. Boiler Company has hosted in New England.

Heating contractors attended the event to learn about high efficiency heating equipment, including the Ambient Air-to-Water Heat Pump, Citadel commercial condensing boiler, Alta self-adaptive boiler, and the Ambient electric boiler.

More than 70 contractors attended. Raffle prizes were given away and attendees played a variety of games for an opportunity to win Carhartt tool bags, van wrap packages and a smokeless firepit from Solo Stoves.

“I attended the event because I have a passion for learning about products,” said George Narváez, owner of Littleman Heating in Framingham, MA. “It builds my knowledge and confidence when speaking to customers, doing installations or servicing.”

“I enjoyed getting an up-close look at an Alta boiler that was opened for display,” he continued. “The team was fantastic and happy to answer all my questions.”

U.S. Boiler Company will hold more Hops to Heat events in 2025. For more information or training opportunities, visit www.usboiler.net to learn more.

In 1971, Chicago native James Guercio, a musician and producer, purchased a 2,000-acre ranch in Nederland, CO, with plans to turn the property into a recording studio and rural escape for the biggest names in the music business. He modified the property’s old barn into a recording studio. In ‘72, Joe Walsh recorded “Rocky Mountain Read more

In 1971, Chicago native James Guercio, a musician and producer, purchased a 2,000-acre ranch in Nederland, CO, with plans to turn the property into a recording studio and rural escape for the biggest names in the music business.

He modified the property’s old barn into a recording studio. In ‘72, Joe Walsh recorded “Rocky Mountain Way” while the barn still had a dirt floor. This was the first of many hits that would be produced at Caribou Ranch, as Guercio called the estate. Other stars followed, including Elton John, Stevie Wonder, Chicago, John Lennon, Michael Jackson and hundreds more.

The 3,300 square foot home was a guest residence for musicians recording at the Caribou Ranch Studio.

On a parcel adjacent to the ranch sits a 3,300 square foot home built in 1973, where many of the travelling artists took up residence while writing and recording music. Fast forward to 2022: the home – and the piece of music history it represents – was sold.

The new owner found one of the old boilers leaking and called Peak to Peak Plumbing & Heating.

“We’re one of only a few shops that regularly travel up the Peak to Peak Highway to serve rural customers,” said Joe Ryan, 33 years old and owner of the company.

Ryan found that neither the old cast iron boiler nor the electric boiler was leaking. Instead, the water came from a foundation leak. To address that issue, Ryan called a general contractor he works with on a regular basis, Tom Akins, who owns AP Construction.

After some deliberation, the owner decided to renovate the entire home.

Joe Ryan, owner of Peak to Peak Plumbing.

Ground-source or air-source

Plans were drawn to update the house as well as the dual-fuel hydronic system installed years earlier. The owner’s two requirements were that heat pumps be used and radiant heating be installed throughout.

“Our first conversation about the heating retrofit took place two years ago,” said Ryan. “Both the homeowner and I were torn between installing geothermal units or an air-to-water heat pump system. Whenever I have questions like that, I reach out to Tommy Carroll at Boulder Winnelson.”

“Tommy’s about my age, casual and humble, which can be misleading, because he’s an hydronic mastermind,” he continued. “He’s an engineer by training and he designs hydronic systems in his sleep.”

Nearby Boulder is one of the greenest towns in the country, so it’s no surprise that local supply houses might have someone on staff to design high-efficiency, high-comfort hydronic systems.

“We compared air-to-water heat pumps with a geothermal system,” said Carroll. “In the end, it wasn’t a hard decision.”

Using an outdoor design temperature of -2°F, the home required 81,000 BTU/H. Given the ground temperature at 8,700 feet above sea level, a geothermal system would have required five, 500-foot boreholes. That expense alone made air-to-water heat pumps more attractive.

(left to right) Tommy Carroll and Joe Ryan connect thermostat wires.

BTU Wrangler

“Air-to-water systems have come far enough along that they’re somewhat comparable in capacity and COP to geothermal heat pumps,” said Carroll. “In the long run, air-to-water just made more sense. Air-to-water adds some cost to the plumbing side of the project, but the overall cost is significantly less.”

Customers go to Boulder Winnelson with tricky hydronic projects. Carroll’s business card reads “BTU Wrangler” for good reason.

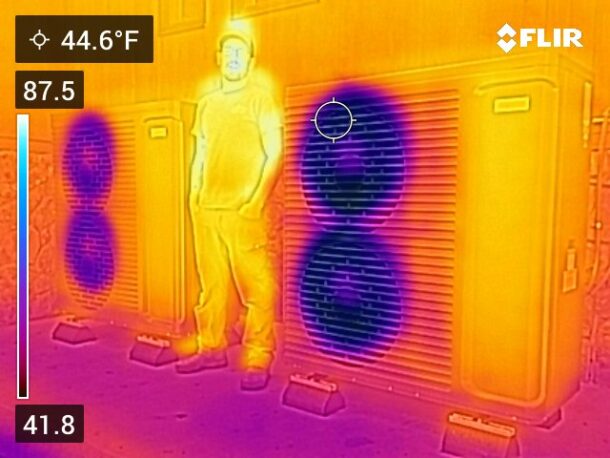

Installer Joe Ryan stands between the Ambient Heat Pumps.

Carroll conducted the heat-loss analysis based on the improvements that AP Construction was making to the building envelope, designed the heat pump system and put together a plan for the controls, allowing Ryan to install two air-to-water heat pumps with a condensing boiler for backup.

“Joe and I have worked together on a few projects in the past,” said Carroll. “He counts on us for experience and expertise, but he’s so competent that he doesn’t need help often.”

Quick pivot

Typical of old, custom homes, the renovation work proceeded slowly, thanks to surprises that kept coming up during construction. Ryan and Carroll had their system design finished in 2023 but were waiting until they could fully implement it. Not much changed until early 2024, when U.S. Boiler Company’s Dave Hansen called on Boulder Winnelson.

“Dave showed me their new Ambient air-to-water heat pump, and the specs on it matched what we needed perfectly,” said Carroll. “So, we changed the design. We’ve had a relationship with U.S. Boiler Company for decades. We knew we could count on them if we needed help.”

Almost a year before the release of the Ambient heat pump, Peak to Peak Plumbing & Heating had already piped many of the indoor components, including a 155 MBH condensing boiler, 70-gallon buffer tank, circulators, sidearm tank, HBX heat pump controller, and more. For this reason, Ryan didn’t need the complete Ambient heat pump package. He just needed the outdoor units.

Two, five-ton Ambient air-to-water heat pumps are used to heat the 3,300 square foot home, which was built in 1973.

“There was an old electric boiler here before I arrived, so the heat pumps didn’t require an electrical service upgrade,” said Ryan. “We just poured a slab outside and core-drilled through the wall to run water lines to the mechanical room.”

Akins, the builder, was mildly concerned that noise or vibration from the heat pumps would transfer through the slab and into the home, but only time would tell.

On the inside

The entire system is freeze-protected by a 35 percent Enviro-Frost glycol mixture. Supply and return lines run from the outdoor units to the large buffer in the mechanical room. This tank has an electrical element but plans to hook it up were discarded when the Ambient heat pumps were selected.

“The Ambient heat pumps are five tons in capacity each,” said Ryan. “They’re capable of supplying up to 140°F water and continue operating down to an outdoor temperature of -13°F. We designed the radiant system to require only 121°F supply water on a design day, and there’s a gas boiler piped to the buffer tank in the unlikely event the home needs supplementary heat.”

When operating at full capacity, 15.3 GPM is pumped through each Ambient heat pump and into the 70-gallon AltSource buffer tank, which also contains a reverse-indirect coil for DHW.

The mechanical room, designed by Ryan and Carroll, uses hot water from the heat pumps for the radiant system and to pre-heat domestic hot water.

“The buffer tank won’t cover the DHW load, simply because it sits at about 120°F on design day,” explained Carroll. “That’s great for radiant floors, but too cool to heat the DHW to final temp. Instead, the coil in the buffer tank just pre-heats the water on its way to the sidearm tank. We went with the reverse indirect coil because it is an easy way – requiring no pumps or moving parts – to use the heat pumps to cover some of the DHW load by preheating the incoming cold water on its way to the sidearm tank. The boiler will always have to raise the DHW to final temp.”

On the space heating load side of the buffer tank is a single Grundfos Alpha circulator distributing water to six zones, which are controlled by a bank of Taco zone panels and Zone Sentry valves.

The entire floorplan is heated with half-inch Uponor PEX, held in place by Legend Valve’s VersaTherm floating floor panel system.

The new mechanical room, wrapped in grey diamond plate aluminum and tongue-and-groove pine, occupies what had previously been a large closet. The 200-square foot room that used to contain the messy old mechanical system is now storage space.

“One of our big draws for making this a dual fuel system with a propane back-up boiler was that the gas boiler can be run off a battery back-up or small, cheap generator in the event of a prolonged power outage,” explained Carroll. “This makes the system more resilient than an all-electric system, which is important up in the mountains where the weather is unpredictable, and the power grid is less robust.

(left to right) – Chris Altenderfer, Tommy Carroll and Joe Ryan.

Evolution

Chris Altenderfer, manager of electric heating development at Burnham Holdings Engineering Company, joined Hansen, Ryan, Carroll and Akins onsite for system start-up. Watching through a Flir infrared device, they waited only a minute to see the heat pumps’ discharge fans turn purple, and the inch-and-a-quarter supply water lines turn red.

“I saw immediately that my concern about noise was unfounded,” said Akins.

“Even running at full speed, the Ambient units are quieter than any mini-split I’ve seen,” he added. “But this was completely new to me. This is the future of hydronics, and most of the homes we build have radiant systems. Peak to Peak Plumbing & Heating is on the cutting edge of the heating industry. Boulder is slowly forcing residents away from fossil-fuel appliances, so I’m excited that Joe is on the front end of the electric hydronic evolution.”

The homeowner is excited, too.

“As we undertook a big renovation, we knew that we wanted to plan for the future,” said the homeowner. “We went with this system for a combination of energy efficiency and the comfort of radiant heat. It helped that we have a great team, led by Joe Ryan and Tom Akins, who are both excited about the system. We couldn’t be happier.”

Anyone with a military background will recall the U.S. Government’s penchant for acronyms. MREs, BDUs, MRAPs, the list goes on. Unfortunately, this dynamic is also present when discussing the efficiency enhancing feature known as outdoor reset. ODT, SWT, LWT, etc. It’s enough to cause a BM in your BVDs! Well, U.S. Boiler Company has once Read more

Anyone with a military background will recall the U.S. Government’s penchant for acronyms. MREs, BDUs, MRAPs, the list goes on. Unfortunately, this dynamic is also present when discussing the efficiency enhancing feature known as outdoor reset. ODT, SWT, LWT, etc. It’s enough to cause a BM in your BVDs! Well, U.S. Boiler Company has once again developed a solution to make all this NBD.

First a few simple facts.

1. Flue gas will condense when temps are at or around 130° or less.

2. When vapor contained in flue gas condenses it releases a significant amount of heat.

3. Without question, optimal efficiency is achieved by heating a home using the lowest possible water temperature that will maintain the desired indoor target temperature, usually the thermostat set-point.

4. Using a Mod-Con, or high efficiency, gas boiler like the ALTA can take full advantage of the condensing action allowed by low water/flue temps.

Outdoor reset sensors do a wonderful thing. They enhance efficiency by matching water temperature to varying conditions. For example, one would want to maintain indoor design temp, normally 70°, during outdoor design temps (in CT normally 7-10 degrees.) Assume a 7° ODDT, and required SWT of 180. This means the boiler must deliver 180° supply water consistently at a 7° outdoor design temperature to maintain the desired indoor temp (IDT). This all simply means we need the hottest water when it’s coldest outside. Good so far?

As Paul Harvey used to say, “And now-The rest of the Story!” We now all understand (hopefully) what happens in our heating systems on the coldest day of the year. What about the rest of the time? Sure, that 180° water will heat the house just fine on a 50 degree day. But what about all the energy used to unnecessarily heat the water way past what would be required to keep the home comfortable? This is a net negative on many fronts, but most significant is the increased wear and tear on the heating unit.

So, your now asking “Tom, how low can my water temp be?” The answer will likely surprise you. Standard fin tube radiation works ok down to 130° water temps in most applications. Same with cast iron radiators. For the fin tube baseboard system in my house the minimum boiler water temp on my ALTAC-136 is 125 degrees. Hydro-air (hydronic coils added to or contained within hot air furnaces or air handlers) can often be run around 130° as well, depending on the occupant’s expectations. Remember, these SWT’s are typically targeted when the ODT is ~70°. We don’t need to transfer much heat to maintain indoor setpoints at these conditions. How does all this magic happen? Outdoor reset. Using a thermistor mounted outside, typically out of the sun on the north facing wall we monitor ODT and adjust SWT temp accordingly. So my personal curve used to be 180° SWT @ 7° ODT, and 125°SWT@70° ODT, but no more. My ALTA figures this out automatically without an outdoor reset sensor.

While outdoor reset simply monitors outdoor temperatures, rate-based reset works by looking at boiler run time, firing rate, and other parameters and adjusting accordingly. Here’s a few examples. Say it’s a beautiful spring day. Nice and sunny with a gentle breeze and 50° outdoor temperatures. The boiler run times are likely short, and the firing rate is likely low. The boiler knows from these conditions the heat loss from the house is minimal, and adjusts, incrementally dropping the boiler water temp until the minimum setpoint is reached, or our algorithm (the “secret sauce”) calculates that based on run time and firing rate the water temp will deliver enough heat to match the rate of heat loss and maintain indoor temp setpoints at the lowest possible SWT. As night rolls in and the temperature drops, average run times and firing rates increase, and once again, rate-based reset will adjust (increase) SWT’s to maintain indoor comfort and optimal efficiency. “Brilliant!” you say. I agree. But wait-there’s more!

Conventional ODR has limitations. Say the calculated water temp for a 45 degree day is 142°. It’s a moderately windy day. Consider two different houses, both 2,500 ft. The first has a well-sealed envelope, double pane windows, and effective insulation. The second has old single pane windows, minimal (or no) insulation, and is as drafty as old fence. The boiler doesn’t know what the indoor conditions are, just that it must target 142 degrees. That 142° SWT might be fine for the first, but far too low for the second. Now to be fair, all U.S. Boiler products with outdoor reset offer a “boost” feature that will automatically bump the temperature up every “X” (boost time value) minutes, default being 20. This means every 20 minutes with an uninterrupted call, the SWT will rise 10 degrees until the max setpoint is reached. The benefit of rate-based reset is we are always looking at indoor conditions and adjusting accordingly. Rate-based reset always uses the lowest possible water temp that will maintain the desired indoor temp, and then has the boost feature if an increase above the calculated target temp is required. Like a samurai sword: simple, elegant, and effective!

There are other benefits as well. Remember the test I mentioned? Here it is. What factors showcase the benefits of rate-based reset? See the answers below. Correct your test answers accordingly…

1. No sensor to install. Rate-based wins!

A) No sensor for landscape professionals to damage.

B) No sensor for contractor to install (or throw away!)

C) No wire required from boiler to sensor.

D) No worries about where the contractor will mount the sensor, if it will be impacted by the sun, or heat migration from the interior affecting the sensor calibration.

E) Enabled from the factory. No worries for homeowner regarding whether the contractor enabled ODR. The Alta boiler is set up for maximum comfort and efficiency right out of the box!

2. No Lemon Faces! Rate-based wins!

A) Always monitoring indoor temp. Onboard algorithms are constantly at work to meet heating demands while maintaining maximum efficiency. Tens of thousands of units installed with zero complaints about indoor temperature. When not writing informative and engaging articles such as this, I am a member of the renowned U.S. Boiler tech support team. I’ve honestly never received one complaint regarding rate-based reset. If you have, please contact me.

B) Not reliant on a technician with advanced, comprehensive knowledge of ODR curves. Works fine out of the box with no programming in most applications, and, where required, only minimal adjustments for almost all applications, including low temp radiant.

C) If the homeowner is made aware that during mild temperatures the radiators will not be the same temperature as the skin of the space shuttle during re-entry, and that these cooler temperatures mean more money in their pocket for candy/wine/shuffleboard, they will instead have smiles every time they touch the radiator. Or better yet, they will abandon the practice entirely…

3. Takes full advantage of condensing aspect of mod con boilers. Again, rate-based wins!

Regardless of ODT, rate-based reset always targets the lowest possible temp, thereby maximizing the potential for the boiler to run cool enough to operate in a range where flue gas condensation occurs.

I can almost feel grizzled old contractors firing up HP 386’s and waiting for the comforting squawk of their dial up modems connecting. I imagine most of the responses will begin with:

“Dear factory stooge/shill. Your article may fool the unwashed masses, but not me. My mom’s uncle’s grandmother has a hunting cabin with 1 radiator and 600 feet of ¾” pipe to connect the boiler to the house (it’s in the barn where we milk the squirrels). How does your new-fangled boiler work in my application? Hah!!! Gotcha!!!”

It will be this, or something substantially similar. There’s always at least one. For the rest of the world (and fortunately, most of the squirrels) these anomalies are rare. There is no magic solution for a poorly designed or installed system. But when a competent, capable, and progressive contractor is installing a new or replacement system, the advantage of rate-based reset over conventional sensor-based reset is clear. Reduced (or no!) programming required, no wires to pull, and no exposed exterior sensor susceptible to damage. Save time, money and aggravation. Go ahead and skip a step with ALTA.

For more information on the Alta boiler, visit our Alta Product Page.

GUEST BLOGGER: Tom Secondino is a Technical Sales Support Specialist for U.S. Boiler Company, a manufacturer of residential and commercial heating products, including condensing, non-condensing and electric boilers.

GUEST BLOGGER: Tom Secondino is a Technical Sales Support Specialist for U.S. Boiler Company, a manufacturer of residential and commercial heating products, including condensing, non-condensing and electric boilers.

U.S. Boiler Company introduces the all-new Citadel and Citadel XL condensing boilers and volume water heaters. The Citadel is available in five capacities (399 – 1000 MBH) and the Citadel XL is available in 1250 and 1500 MBH capacities. AHRI certified and rated up to 97% thermal efficiency (98% for water heater), the Citadel is Read more

U.S. Boiler Company introduces the all-new Citadel and Citadel XL condensing boilers and volume water heaters. The Citadel is available in five capacities (399 – 1000 MBH) and the Citadel XL is available in 1250 and 1500 MBH capacities. AHRI certified and rated up to 97% thermal efficiency (98% for water heater), the Citadel is available in either a natural gas or propane configuration.

The new boilers save time, space and simplify design and installation. The Citadel can be stacked two-high without the need for accessory racking systems, while the Citadel XL can be stacked with a rack system. Zero side and top clearance optimizes the amount of BTUs that can offer per square foot.

Because the Citadel is designed for the widest variety of applications, it’s sold complete out of the box. Included at no additional cost are the low water cutoff and high and low gas pressure switch making the boilers CSD-1 compliant. A standard, reinforced 3-in-1 vent connector facilitates the use of polypropylene, CPVC or stainless steel venting on the Citadel. Venting of up to 300 equivalent feet (combined) of vent in AL29-4C, polypropylene or CPVC is acceptable. Modbus communication also comes standard.

In addition to standard 10:1 turndown and impressive 300 GPM maximum flow rate, an outdoor model is also available for all but the largest models at no additional charge. Citadel XL models are available with 208/60hz/1ph and 230/60hz/1ph electrical options.

For more information, please visit www.usboiler.net

The past few years have been good for contracting businesses, barring component availability and skilled labor woes. For anyone in the trades, operating a plumbing and mechanical company profitably looks different today than it did 20 years ago, but there are still plenty of similarities. Joe Tull, 36, founded Straight Plumbing, LLC seven years ago Read more

The past few years have been good for contracting businesses, barring component availability and skilled labor woes. For anyone in the trades, operating a plumbing and mechanical company profitably looks different today than it did 20 years ago, but there are still plenty of similarities.

Joe Tull, 36, founded Straight Plumbing, LLC seven years ago, and feels as though he’s settled into a sweet spot. Right now, that includes running two trucks and focusing on Maryland’s Hartford County and northern Baltimore County. The company used to be bigger, but not necessarily better, according to Tull.

Roughly 30 percent of Straight Plumbing & Heating’s work is hydronic heat. The rest is residential and commercial plumbing service.

“I’ve always preferred quality over quantity,” he explained. “When I had more employees, I spent a lot of time going behind them and fixing their mistakes or shortcuts. Right now I have a fantastic apprentice, Robert Howard, who’s been with me four years. He’s always respected me and done things my way, which simply means not cutting corners. I’d hire 20 like him, if I could find them.”

Joe grew up working for his father’s plumbing company, but after a while, the two Tulls couldn’t see eye to eye. So Joe left and spent several years on the plumbing service crew for a large company before hanging out his own shingle in Jarrettsville, Md.

Specialization

“Specialization gives the people . . . the opportunity to go further in any direction of study than any other human has gone before.” – Ryan North

“Service is what I knew best, and what I could build a reputation on most rapidly,” said Tull. “Service work also provides the greatest opportunity to solve people’s problems. The new construction side of the business is more volatile. So I specialized in plumbing service, and as soon as I was up and running, I dug into hydronics to expand our offering.”

Joe Tull founded Straight Plumbing, LLC in 2016, after working for his family’s company and several other plumbing firms in the area.

Today, 30 percent of Straight P&H’s work is hydronic heat. The rest is plumbing service, both residential and commercial. Due to the rural nature of his territory and the presence of hard and harsh water, many of their service calls involve well pumps and water conditioning. A deep understanding of water quality has infinity improved Tull’s hydronic and plumbing work.

Forging relationships

“Technology does not run an enterprise, relationships do.” – Patricia Fripp

Tull learned early in his career that relationships are critical to the success of a business. In addition to learning from his father, he had mentors at supply houses, rep firms and within his social circle.

“I had a lot to learn when I first started installing boilers” said Tull. “Jim Bull, at Thomas Somerville became a mentor. He has a wide range of heating knowledge and was always generous with that information. He’d even stop at my jobs in the evening and set me straight if I was in a bind.”

Relationships are as important to Tull today as they were then, when he was still building his portfolio of experience.

“I try to be an information sponge and do my best to become an asset to the people who add value to my life,” said Tull. “Over the past three years, I’ve worked closely with the reps at ROI Marketing, specifically Dan Byrne, district manager, and Dave Raabe, sales manager. Those guys are never more than a phone call away.”

“I try to be an information sponge and do my best to become an asset to the people who add value to my life,” said Tull. “Over the past three years, I’ve worked closely with the reps at ROI Marketing, specifically Dan Byrne, district manager, and Dave Raabe, sales manager. Those guys are never more than a phone call away.”

Byrne has known Tull for more than 20 years, but has only been his hydronic rep for about three years, after helping Straight P&H sort out some technical issues on a particularly challenging project. Tull installs their line of U.S. Boiler Company condensing and cast iron boilers, ComfortPro PEX, State water heaters and Webstone valves. Some of that equipment comes through Jordan Mitchell, at Northeastern Supply, while some is sourced at other supply houses throughout the area.

Straight Plumbing & Heating used to be a larger company, but Tull intentionally reduced it to two trucks for the sake of quality and consistently.

“Dave and Dan rock,” said Tull. “Their support, and the help I’ve received from the factory tech support at U.S. Boiler has been outstanding. I’ve used other boiler brands with less success and non-existent customer service.”

Byrne and Raabe visit Tull’s jobsites a dozen times or so each year, often on the front end, to provide sizing assistance, system concepts, etc.

“What I observed when I first met Joe was a young guy that wanted to install stuff properly,” said Raabe. “He’s very talented and his work is extremely professional, yet he’s humble and not afraid to ask for help.”

“I wish all our customers were like Joe,” added Byrne. “He takes real pride in his work.”

Referral marketing

“Courteous treatment will make a customer a walking advertisement.”

– James Cash Penney

“I left my previous job because I saw customers being taken advantage of,” Tull said. “I don’t hard-sell anyone. I present their options along with fair pricing and let them decide what they prefer. I want customers for life. If I’m fair and I do the job to the best of my ability, my customers become my salesforce.”

Tull doesn’t just talk the talk. His 38 five-star reviews on Facebook are proof enough. One review states, “Joe came to my house and fixed me up. After I got estimates from other plumbers that were way too expensive, Joe fixed my old water treatment system without pushing me to buy a new one. He simply stated ‘Please think of me when you decide to upgrade.’ And you bet your butt I will.”

Create value

“You don’t get paid for the hour. You get paid for the value you bring to the hour.” – Jim Rohn

Straight Plumbing and Heating creates value as well as anyone in the business. Homeowner Steve Shelley learned this when he first hired Tull to solve some minor plumbing issues. Years later, when it came time to replace the home’s oil-fired boiler, Joe was his first and only call.

“Joe is very responsive, knowledgeable and thorough,” said Shelley. “He doesn’t try to oversell, he’s happy to answer questions, and he’s never in a rush to get things done. I didn’t have to think twice about hiring him to convert our home from oil to propane, which we did mainly for the energy savings.”

The combi boiler system Tull installed heats the home through a hydronic air handler, while also providing more hot water than the homeowner had ever had in the past.

The home is heated by hot water fan coils, and the existing boiler used to provide DHW through a 40-gallon indirect tank. Shelley estimates that the unit burned 800 gallons of oil each year, or roughly $3,200.

Tull buried a large propane tank in the yard, replaced the existing unit with a 200 MBH Alta Combi boiler, and sidewall vented the new unit.

The retrofit took place in June last year, giving Shelley nearly a year to calculate the energy savings that Straight Plumbing and Heating had provided.

“We used 400 gallons of propane over the winter, and I’m sure we’ve consumed a little more through the fall and spring for hot water,” he Shelley. “With LP at $2.00 per gallon, we’re saving somewhere around $2,000 per year.”

Tull replaced an oil-fired boiler with a new Alta condensing combi boiler for an annual savings of $2,000.

Shelley also noted that the family used to run out of DHW quickly. Now they can shower as long as they want and run multiple taps.

“We have all the hot water we need,” Shelley explained. “We can’t smell oil in the basement anymore, and we don’t hear the boiler start up like we used to.”

“We have about a dozen Alta boilers in the field,” said Tull. “They work very well on LP. Most of the installations in Hartford County are on propane. The Alta is also easy to clean, and access is fantastic because the side panels are removable.”

There’s another reason that Tull installs the Alta. Much like other models in the U.S. Boiler Company lineup, the Alta is available at a variety of local supply houses, including Northeastern Supply, Thomas Somerville and R.E. Michel.

“When it’s cold and a customer needs heat, I can’t come up empty-handed on parts and product,” said Tull. “Having equipment that’s readily available is extremely important.”

Overcoming challenges

“A challenge only becomes an obstacle when you bow to it.” – Ray Davis.

Last heating season, Straight Plumbing and Heating installed 35 boilers. This year, only 20. He suspects the economy has something to do with that, but he’s certain there’s another reason.

According to Tull, many big HVAC companies are pushing homeowners toward inexpensive heat pumps. There are lots of “house flippers” in his territory, as well. Typically, flippers install the cheapest heat pump on the market.

Straight Plumbing & Heating has a dozen Alta boilers in the field, and he’s found them to be reliable and very easy to work.

“I’m not talking about high-efficiency, low-ambient temperature systems,” he said. “I mean the cheap, undersized unitary systems. I’ve had homeowners call me after buying a house with a new heat pump, asking if I can install ‘a real heating system.’ Once winter hits, they’re uncomfortable and their electric bill spikes because the units constantly run on emergency heat.”

It’s hard to sell a premium system against a budget option when the customer doesn’t know the difference before signing the contract.

“I know it will all come full circle,” said Tull. “You only make that mistake once. If I was trying to grow rapidly, I’d be concerned about it, but I’m happy with where the company is. It’ll grow gradually. We’ll continue solving harsh water problems and creating extremely comfortable heating systems. If we do that and remain transparent with our customers, the company will continue to do well.”