In the dynamic world of heating and cooling, hydronic systems have established themselves as unsung heroes. By using water or other liquids as heat carriers, these systems offer an energy-efficient, eco-friendly solution for temperature regulation. Their brilliance, however, isn’t solely in their design; it’s in their heart—filtration. Proper filtration ensures a clean, debris-free flow, acting Read more

Featured Articles

In the dynamic world of heating and cooling, hydronic systems have established themselves as unsung heroes. By using water or other liquids as heat carriers, these systems offer an energy-efficient, eco-friendly solution for temperature regulation. Their brilliance, however, isn’t solely in their design; it’s in their heart—filtration. Proper filtration ensures a clean, debris-free flow, acting as the guardian of efficiency and the protector against wear and tear. By ensuring that water circulates free of contaminants, filtration ensures that the entire system remains efficient, robust, and long-lasting, ultimately offering unparalleled performance day in and day out.

Classifications of Hydronic Systems

The intricacies of hydronic systems are often deeply rooted in their design variations. Each classification serves specific purposes, with unique advantages tailored to diverse applications. Grasping the diversity of hydronic systems not only provides clarity during installation but also ensures optimization of maintenance efforts for each specific design.

- Open Piping Systems: Characterized by a direct connection to the atmosphere, usually through an expansion tank.

- Direct Return Piping Systems: A straightforward design with water returning directly from the terminal to the boiler.

- Reverse Return Piping Systems: More balanced than direct returns, as the water travels the same distance, regardless of where it starts or ends.

- Closed Piping Systems: Isolated from the atmosphere, these systems reduce the risk of contamination.

- Direct Reserve Combination Return Systems: A blend of direct and reverse returns, offering flexibility.

- One Pipe Systems: A simple setup where a single pipe serves both the supply and return.

- Two Pipe Systems: Features separate pipes for the supply and return, providing more precise temperature control.

- Three Pipe Systems: Incorporates an extra pipe to boost heating or cooling capabilities, often used in more complex applications.

- Four Pipe Systems: Offers ultimate flexibility with separate pipes for heating and cooling, allowing simultaneous operation of both functions.

- Radiant Panel Systems: Leveraging radiant heat transfer, they warm or cool surfaces rather than air.

The Imperative of Regular Filtration Maintenance

Maintaining a hydronic system’s efficiency isn’t just about periodic check-ups; it’s fundamentally rooted in robust filtration maintenance. Every component of a hydronic system relies on the purity and consistency of the liquid it circulates. Without diligent filtration maintenance, impurities can accumulate, leading to blockages, reduced efficiency, and long-term system damage. Beyond the health of the machinery, when systems aren’t optimized, they can consume more energy, raising operational costs substantially.

The U.S. Department of Energy’s Energy Saver Guide underscores the significance of regular maintenance for heating and cooling equipment, stating that it’s vital for ensuring efficiency. Diligent care ensures potential issues are detected early, keeping systems running smoothly and reducing unforeseen expenditures. With regular attention to filtration, operators can guarantee that hydronic systems deliver peak performance while making a significant impact on their bottom line.

Inspections Are Key

While regular maintenance sets the stage for optimal system functioning, it’s through rigorous inspections that the true health of a hydronic system is gauged. By methodically examining each component, operators can pinpoint minor issues before they escalate into costly problems. Inspections provide a comprehensive overview, from the cleanliness of the filters to the efficiency of the pumps.

During these assessments, technicians often encounter subtle signs of wear or potential failure points that might go unnoticed during regular operation. Armed with the insights from these inspections, operators can implement proactive measures, ensuring longevity and consistent performance. For a hydronic system to thrive, a meticulous inspection regimen is non-negotiable. It’s the bridge between everyday operations and the assurance of system durability.

Choosing the Right Filter System

Selecting the proper filter system for your hydronic setup isn’t just a technical task; it’s foundational to the longevity and efficiency of the entire operation. There are a few key factors that you need to consider when selecting the system that is the right fit:

- Consider the specific demands of your hydronic system. Is it a commercial setup with high volume needs or a more modest residential system?

- Take stock of the kind of contaminants you’re primarily dealing with. Different locales and water sources might introduce varied impurities, from mineral deposits to organic matter. Understanding these variables will guide you to the right filtration granularity and type. Remember, over-filtration can be as detrimental as under-filtration, leading to undue pressure on the system and increased energy costs.

- Think about future scalability. Systems grow, demands shift, and an ideal filter system can adapt without necessitating an overhaul. Aligning your choice with not only your current needs but also future projections ensures that your hydronic system operates at peak efficiency today and well into the future. Making the right choice in the beginning can save you significant time and money down the line.

Maintenance Tracking: Don’t Leave It to Memory

In the bustling world of hydronics, where efficiency meets innovation, it’s crucial to keep a meticulous record of every maintenance activity. But let’s face it, relying on memory or scattered notes is a path laden with oversights. With the high-tech nature of modern hydronic systems, maintenance isn’t just about swapping out parts; it’s about understanding trends, foreseeing potential issues, and optimizing operations.

Using dedicated tracking tools or software can be a game-changer. Not only do these tools ensure that no maintenance milestone is missed, but they also provide invaluable data over time. This data can be used to understand the system’s behavior, predict when parts might wear out, and even optimize the entire operation for better efficiency. In the event of unforeseen malfunctions, having a comprehensive maintenance log can expedite troubleshooting, getting your system back up and running in no time.

Guest Author: Mark Ligon is the Marketing Manager at Commercial Filtration Supply, a provider of industrial filtration products at discount prices. Mark enjoys writing about various liquid filtration applications, and he believes educating customers on liquid filtration best-practices ensures they have the best experience possible with the product they decide on.

Guest Author: Mark Ligon is the Marketing Manager at Commercial Filtration Supply, a provider of industrial filtration products at discount prices. Mark enjoys writing about various liquid filtration applications, and he believes educating customers on liquid filtration best-practices ensures they have the best experience possible with the product they decide on.

According to Forbes, the occupancy rate among US multi-family housing units rose to 96.9 percent in mid-2021, and the trend has continued post-pandemic. With real-estate prices increasing sharply and rent costs reaching all-time highs, there’s more incentive than ever to renovate, update and repurpose commercial and light commercial facilities, whether properties include multi-tenant housing, mixed Read more

According to Forbes, the occupancy rate among US multi-family housing units rose to 96.9 percent in mid-2021, and the trend has continued post-pandemic.

With real-estate prices increasing sharply and rent costs reaching all-time highs, there’s more incentive than ever to renovate, update and repurpose commercial and light commercial facilities, whether properties include multi-tenant housing, mixed office space, retail locations, etc.

Brandon Content, at Plumbing Systems Inc., establishes a connection between several boilers and the tekmar control system that serves the large vacation home.

Compared to new construction, however, this leaves property owners, managers and mechanical contractors at a disadvantage: older but serviceable mechanical equipment can be difficult to integrate with a smart and connected control platform.

This may be especially true in northern climates, where hydronic systems have been the default source of space heat due to boiler efficiency, comfort, longevity and the ability to provide ample domestic hot water.

Staging and remotely monitoring boiler plants without a BAS installed has become easier than ever with next-generation control modules.

Older boiler plants generally lack connectivity in the 50,000-square-foot and under market, where installing a building automation system (BAS) may not be worth the expense.

James Dice, PE, CEM, CMVP, founder of Nexus Labs, recently wrote a white paper titled “The Untapped 87%: Simplifying Controls Technology for Small Buildings.” In it, the author explains that a 20,500 square foot building was retrofitted with a BAS by the United States Department of Energy’s Pacific Northwest Laboratory (PNNL) in 2010. Within the first two years, this lead to a 22% energy savings, 25% return on investment and a “dramatic decline” in occupant comfort complaints.

The white paper goes on to explain that buildings smaller than 50,000 square feet represent 94% of commercial buildings in the US, 44% of electricity use, and 44% of total energy use. Yet, only 13% of these buildings are equipped with a BAS.

High-end vacation homes benefit from remote boiler system access, as well as most commercial systems.

The reason? BAS systems are either too complex or not cost effective enough for the average building owner. BAS frequently cost $50k to $100k, which exceeds the fiscal budgets of many building owners. In addition, they require an expensive annual service plan.

Because of this, there is massive opportunity to reduce energy consumption and simplify maintenance with the use of new, connected HVAC system controls without installing a BAS.

Aging boiler plants

Many commercial boiler plants feature multiple boilers for staged input or redundancy. Over the years, as various boilers were replaced, it’s not uncommon to have multiple different boiler models serving the same system.

For example, a system that was originally served by three conventional boilers of the same model might have been retrofitted with a single condensing boiler to replace two of the originals, while the third existing boiler remained in place for supplemental heat on design days.

In new construction applications or in systems where every boiler in the system is replaced, the boiler manufacturer’s onboard cascading controls are often used for lead-lag cycling of the units, though establishing remote access can still be a frustration.

Three oil-fired boilers now serve a hydro-air system at a recreation building, using smart boiler controls to control all three units and provide remote access.

Fleet management is a major problem for facility managers. The heating system equipment is usually different in every building. This is due to the buildings being built and updated at different times, and buildings being acquired and sold by the management company.

So facility managers, property owners and mechanical contractors involved with light commercial systems too small to warrant the installation of a BAS are left asking how to control and remotely monitor their systems. If multiple properties are involved, the challenge is multiplied.

Evolving needs

“We’ve been building multi-stage boiler controls for over 30 years,” said Jay Vath, life cycle engineer at tekmar Control Systems. “There are a number of other control manufacturers with similar products, and for everyone in this market sector, the initial goal was to provide outdoor temperature reset for boilers that didn’t offer it.”

The demand for features in a boiler control package evolved along with the boilers themselves, along with the need for greater efficiency and control. Boiler manufacturers began offering outdoor reset and onboard staging across multiple, identical units. So the focus shifted to remote access, existing boiler plants, and the installation of hybrid condensing and non-condensing boilers plants.

Firing a multi-boiler system

Control manufacturers introduced modules that offered some degree of remote monitoring capability for boiler plants, but one large issue remained: Many existing boiler plants included disparate models, often with decades separating them. There was no way to aggregate different brands and models onto a single, web-enabled control platform short of installing a BAS.

Long-sought solution

The primary drawbacks to installing a BAS solely for boiler plant control in a facility that otherwise doesn’t need it are the initial and maintenance cost, but equally important is the level of responsiveness on the part of the controls contractor. A BAS system creates an additional hurdle between the system and the service contractor. If an alert is generated by the boiler plant, the controls contractor – who may or may not be responsive in a reasonable amount of time – notifies the service contractor.

Eliminating the controls contractor and creating a direct conduit from the boiler plant to the service contractor reduces expense and expedites the service response.

A service tech uses the boiler control to check system operation.

“This is a key consideration for any connected boiler control,” said Vath. “It puts power in the hands of the service contractor, while providing remote monitoring capability for systems that may feature a number of different boiler makes models.”

Tekmar’s Smart Boiler Control 294 is an internet connected control that can be accessed via any web-enabled device for remote boiler plant monitoring and control. A boiler wizard provides integration with thousands of boiler models, and various levels of control and permission can be set for specific individuals, such as the service contractor, a facility manager and the building owner.

Compound savings

“Installing a smart and connected boiler plant control system provides real potential to save money on energy and maintenance,” said Vath. “Compared to a fixed operating setpoint system, outdoor reset alone can save upwards of 30 percent in fuel expenses.”

But there are many other savings advantages, some not as easy to quantify. Automatic boiler and pump shutoff reduces energy use when the system isn’t needed. Short-cycling is reduced or eliminated. Rotating boilers balances runtime hours, providing maintenance and longevity advantages. Staging boilers correctly helps accurately match the heating input to the load. Conventional and condensing boilers in the same plant can be grouped together and staged independently, keeping the least efficient appliance offline until needed. Some savings though, take place outside the mechanical room.

“With the notifications and insight that web-enabled boiler controls provide, the service technician knows what’s needed in the event of an alert, which they receive via email, text or push notification,” said Vath. “For example, a pressure input could indicate that the expansion tank’s diaphragm is flooded, so the technician would know in advance to put a replacement in the truck. With remote monitoring, dispatching occurs quickly. Alternatively, if the control generates an alert on an issue that can wait until the next scheduled service interval, an unnecessary trip is eliminated. This kind of information reduces unnecessary expense and allows service professionals to be proactive. The Watts OnSite app provides notifications when boilers and pumps are due for servicing based on run time hours. This allows for the creation of scheduled maintenance plans.”

“With the notifications and insight that web-enabled boiler controls provide, the service technician knows what’s needed in the event of an alert, which they receive via email, text or push notification,” said Vath. “For example, a pressure input could indicate that the expansion tank’s diaphragm is flooded, so the technician would know in advance to put a replacement in the truck. With remote monitoring, dispatching occurs quickly. Alternatively, if the control generates an alert on an issue that can wait until the next scheduled service interval, an unnecessary trip is eliminated. This kind of information reduces unnecessary expense and allows service professionals to be proactive. The Watts OnSite app provides notifications when boilers and pumps are due for servicing based on run time hours. This allows for the creation of scheduled maintenance plans.”

Using a flexible boiler plant control also offers cost saving options in the event of a retrofit. If the ability to connect an old boiler to a new control system is the only factor prohibiting a facility from leaving existing capacity online while retrofitting a portion of the mechanical system, that’s no longer a concern. New boilers can be paired with old boilers for backup heat, ultimately reducing the amount of new firing capacity needed.

Forward-backward compatibility

“For systems that already include tekmar boiler controls, updating the system with the 294 is simple,” said Vath. “All the equipment applications we’ve had in the past are covered by the 294.”

Similarly, the 294 can be quickly updated as new apps or other improvements are introduced. Updates and new features are sent to existing units as they’re developed. This is a big advantage for code compliance.

“In the future, if certain codes are accepted that require specific monitoring parameters, the 294 is designed to be updated to provide reporting as required.”

New hydronic system control packages are changing the way large residential and light commercial boiler plants are monitored and maintained.

This flexibility allows the owner to remain current, not just to become current now. It’s a matter of being proactive, not reactive.

For example, 30 U.S. municipalities across the US are currently phasing in higher standards for commercial real estate emission reductions and energy consumption. A long-known problem is that systems become less efficient over time due to poor maintenance. Remote monitoring is a key method to keep the boiler system operating at the designed efficiency.

Customized control

Web-enabled boiler controls offer a “BAS Lite” solution. With that comes substantial customization.

“The fact that dissimilar boiler technology is being controlled by a single system, tailored to the needs of an individual customer and property means that the control platform has to be extremely versatile,” said Vath. “For that reason, the 294 can be configured for many combinations.”

Staging and remotely monitoring boiler plants without a BAS installed has become easier than ever with next-generation control modules.

For example, a fixed “lead” boiler can be established, in the event that a draft is needed for one of the boilers in the system. A fixed “last” can also be established in the event that a conventional boiler is used only under design conditions, allowing condensing units to fire first.

Control can be established for firing rates or water temperatures, and the system can switch between the two depending on the call for heat. A DHW call may create a water temperature setpoint while a call for space heat may dictate boiler firing rate, and so on.

Security and ownership

Much of the remote access in buildings from the past 20 or 30 years was closed-loop, like key card room access, fire alarms, auto-dialers, etc. To provide full-featured remote access to a variety of team members, an internet connection is needed for a cloud-based platform.

“Fundamentally, where we’ve changed gears from what was done in the past is connectivity,” said Vath. “Once the 294 is connected via Wi-Fi or Ethernet, we use the Watts Onsite app or browser interface to remotely access the device with the ability to adjust every setting in the control. This has a great deal of value for property management groups that have a fleet of buildings, seeking control consistency across properties and boiler plants.”

Security is built into the control and into the Microsoft Azure platform that it operates on. Access is end-to-end encrypted, just like a banking app. Login information is specific to each individual on the team and does not need to be shared among members. The physical control also includes a passcode to prevent unauthorized access.

The program and information resident on the physical controller is a digital twin of the control on the remote device. The virtual device can be modified in real-time, immediately updating the physical device. This reduces trips to the property and allows every member of the team to access the system. Team members who have access to the digital twin can be added and removed, and different levels of access can be established for each.

The new control offers as many advantages to the owner as it does to the service professional. Ownership can be transferred in the event of property sale. Transfer of responsibility is quick and simple, if the service contract changes hands.

The property owner can also monitor and review the responsiveness of the contractor. An acknowledgement is logged when the service professional reviews the alarm. This allows the owner to see if they’re receiving the service they’re paying for.

Ultimate flexibility

Creating remote access for existing light commercial boiler plants requires a great deal of flexibility. Varying loads, miss-matched boiler models and different building codes to conform to all require a control package to be extremely flexible. Looking ahead, the potential addition of air-to-water heat pumps is something that a modern boiler plant control system has to be able to facilitate.

“The only constant is change,” said Vath. “Building owners change, technology changes, service contracts change, codes change. A modern boiler control package must adapt to these transitions.”

This piece was contributed by Eric Balt, technical sales manager for tekmar Control Systems and Mercedeh Fallahkhair, senior product manager for tekmar Control Systems

References:

Dice, J. “The Untapped 87%: Simplifying Controls Technology for Small Buildings”, Accessed June 2023

Cole, R. (2021, November 8). These are the Multifamily Trends Experts Are Predicting for 2022. Forbes.https://www.forbes.com/sites/reginacole/2021/11/08/multifamily-trends-in-2022/?sh=523a0e4b82bb Accessed June 2023

Sadovi, M. W. (2022, November 29). Five US cities target building energy use, emissions with fines. CFO Dive. https://www.cfodive.com/news/five-us-cities-target-building-energy-use-emissions-fines/637538/, Accessed June 2023

Our good friend Mike Prencavage Jr., owner of The Family Plumber, Los Alamitos, Calif., and president of PHCC CA-ORSB, and some of his California PHCC constituents, recently took a tour of SoCalGas’s [H2] Innovation Experience and new model net zero home. “We were fortunate to visit the SoCalGas facility in Downey, Calif., more specifically a Read more

Our good friend Mike Prencavage Jr., owner of The Family Plumber, Los Alamitos, Calif., and president of PHCC CA-ORSB, and some of his California PHCC constituents, recently took a tour of SoCalGas’s [H2] Innovation Experience and new model net zero home.

![sustainability, hydrogen fuel technology, renewable energy, SoCalGas’s [H2] Innovation Experience, SoCalGas, heating, cooling, HVAC, plumbing](https://hydronicshub.com/wp-content/uploads/sites/2/2023/08/PHCC-Socal-Tour-78-610x407.jpg)

“We were fortunate to visit the SoCalGas facility in Downey, Calif., more specifically a mockup home that runs off a mix of hydrogen and natural gas. The system is a H2 microgrid; it’s a regenerative system that can operate solely based off a small amount of water input from either a city source or from a desalinized source, or ocean water,” says Prencavage Jr.

![sustainability, hydrogen fuel technology, renewable energy, SoCalGas’s [H2] Innovation Experience, SoCalGas, heating, cooling, HVAC, plumbing](https://hydronicshub.com/wp-content/uploads/sites/2/2023/08/PHCC-Socal-Tour-7-610x407.jpg)

The Innovation Experience is North America’s first-ever clean hydrogen powered microgrid and home. This project demonstrates how carbon-free gas made from renewable electricity can be used in pure form or as a blend to fuel energy systems and communities of the future.

Part of the Experience features clean hydrogen production and storage along with a nearly 2,000 square-foot home that can draw power from solar panels and convert excess renewable energy into clean hydrogen. “Simply put, the net zero home is using solar energy through PV panels, which is then stored in batteries—that’s for the electricity to actually power the home. Then, through an electrolysis method, running the electricity from the battery through water, they are creating hydrogen, which gets stored in a tank which then gets used to mix with the natural gas in the home so that it reduces your natural gas intake from the city by 20 percent,” says Prencavage Jr.

![sustainability, hydrogen fuel technology, renewable energy, SoCalGas’s [H2] Innovation Experience, SoCalGas, heating, cooling, HVAC, plumbing](https://hydronicshub.com/wp-content/uploads/sites/2/2023/08/PHCC-Socal-Tour-18-610x407.jpg)

SoCalGas has made a considerable, multi-million-dollar investment in what they believe is the future of clean renewable energy. “It is truly amazing how technology has gotten to this point for renewables. As the argument has always been we’re switching to electricity—here is California, it has been a huge push—most Californians understand, we just don’t have the infrastructure for this … so this visit opened a lot of minds to an alternative-type fuel source when it comes to a blended mix of hydrogen and natural gas,” says Prencavage Jr.

Listen to more on the SoCalGas visit by listening to the Appetite for Construction podcast here:

Greetings everyone out there in Radio-land, and welcome to our show, Everything You Always Wanted to Know About Air-To-Water Heat Pumps* (*but were afraid to ask). Our hosts John Barba, Director, Sales Training NA, Taco, and Dave Holdorf, Product & Application Instructor – East, Taco, both of whom have a face for radio, are here Read more

Greetings everyone out there in Radio-land, and welcome to our show, Everything You Always Wanted to Know About Air-To-Water Heat Pumps* (*but were afraid to ask).

Our hosts John Barba, Director, Sales Training NA, Taco, and Dave Holdorf, Product & Application Instructor – East, Taco, both of whom have a face for radio, are here to take your questions and, if a miracle occurs, provide you with coherent answers.

And now, here are your hosts, direct via satellite from Cranston, Rhode Island – John and Dave!

John: Thank you everybody, and welcome to our show. I’m John and on the other microphone is Dave. Say hello, Dave.

Dave: Hello Dave.

John: Yep, those 11 semesters at the Connecticut School of Broadcasting are really paying off, aren’t they? Let’s get right to your calls and tackle some questions on Air to Water Heat Pumps. Dave, who’s our first caller?

Dave: First up JB, we have Elliot from Kansas City. Elliot, you’re up. What’s your question?

Caller: Hi, this is Elliot from Kansas City. Am I on?

John: Hi Elliot, you’re live, coast to coast. There are literally tens of people waiting on your question.

Caller: Wow. Tens, huh?

Dave: Okay, maybe dozens. So . . . what’s cookin’ Elliot?

Caller: Well, it’s pretty basic, but – how many BTU’s? What size house can I do with an air to water heat pump?

John: That’s a great question, Elliot. We get more calls about that than anything else. First, understand that any air-based heat pump extracts heat from the air using a refrigeration cycle. And it stands to reason that the colder it gets outside, the less heat there is in the air to, you know, extract.

Dave: That’s correct, JB. So as it gets colder out, the actual output of an air-to-air or an air-to-water heat pump goes down. So when you need more heat, the heat pump is actually producing less heat.

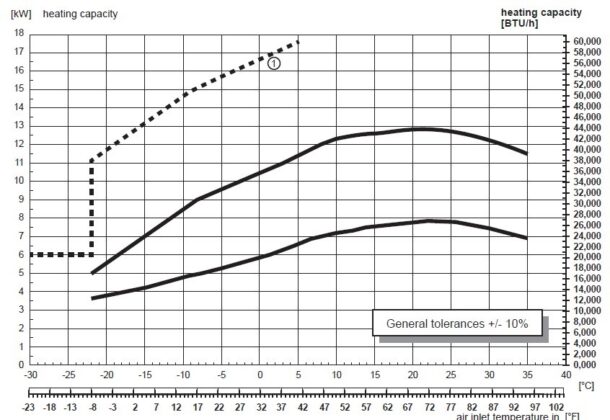

System M output chart:

Taco System M, air to water heat pump, heat pumps, heat pump technology, electrification, heating and cooling, plumbing HVAC

John: As you can see from this output chart for the Taco System M, as the outdoor temperature drops, so does the heat pump’s ability to produce BTUs for heating…

Dave: Uhhh, boss . . .

John: It drops off pretty sharply, as you can clearly see from this chart I’m showing you. When you hit 0o F, the output of the heat pump unit itself is about 21,000 BTUH . . .

Dave: Boss . . .

John: And when it hits its low limit of -7o F, its output is only around 17,000. It’s right there, plain as day.

Dave: Boss . . .

John: WHAT?!

Dave: It’s radio, they can’t see the chart.

John: Oh, right. Sorry. Anyway, that’s the case with any air-source heat pump. That’s why System M also includes a 6kW immersion heater in the buffer tank in its companion indoor unit, the HydroBox. That heater adds another 20,478 worth of potential output to the unit, for a total of just under 38,000 at -7o F.

And don’t fret about the immersion heater coming on willy-nilly. It’s intelligently controlled.

Dave: Willy-nilly?

John: It’s an industry term. Who’s our next caller?

Dave: We have Kyle on the line from the alliterative metropolis of Saskatoon, Saskatchewan.

Caller: Greetings, eh? It can get pretty frosty up here in Saskatoon. Can we hook up some backup heat for when it hits 40 below?

John: Gotta tell ya, my favorite Guess Who song ever is “Runnin’ Back to Saskatoon.” I love how it mentions all those great Saskatchewan towns, like Red Deer, Hanna and Medicine Hat.

John Barba

Caller: Uh, those towns’re in Alberta. Maybe I could talk to Dave instead?

Dave: I got ya, Kyle. It’s very easy to incorporate a backup or auxiliary heat source with an air-to-water heat pump. If the heat produced by the 37,000-plus BTUH System M at -7o F isn’t enough to heat the home, you can have the auxiliary heat come on at -8. Or, let’s say the heat pump/immersion heater combo comfortably heats a home at 10oF above with a total output of 46,000 BTUH, but it can’t take care of the load once it gets colder than 10oF. Then you can set up an auxiliary heat source – like a gas-fired mod-con – or, if the area isn’t allowing any new fossil fuel burning equipment, an electric boiler could meet that need. It’s actually a simple, single pole-double throw switch activated by outdoor temperature. It turns the heat pump off and turns the boiler on.

John: Great answer Dave. That’s exactly what I was going to say.

Dave: Yeah, but you were still runnin’ back to Saskatoon like the McKenzie Brothers. Let’s go to our next caller, Eric in Minnesota. Go ahead Eric:

Caller: (silence)

John: Eric, what’s your question?

Caller: (silence)

Dave: Welp, Eric’s not here. Let’s move on to Pete from Colorado. What’s up, Pete?

Caller: Hi guys. Long time listener, first time caller. Simple question: how does an air-to-water heat pump switch from heating to cooling?

John: Excellent question Pete. There are lots of ways to do it, ranging from a manual switch combined with turning a bunch of valves on and off, to a simpler, control-based solution.

Dave: That’s right, Boss. An integrated control, like the one with the Taco’s System M, uses an outdoor sensor. Based on the type of home, the climate and the level of insulation in the house, you can program an outdoor temperature at which the system goes into heating mode. Let’s say it’s 53 degrees. You can also program in the temperature at which the system goes into cooling mode. Let’s say that’s 63 degrees.

John: Remember gang, these are just examples. But Dave, if you go into heating mode at 53 oF and cooling mode at 63 oF, wouldn’t that leave a sizable dead band between the two?

Dave: Right you are, Sunshine. In that dead band, System M doesn’t do anything except maybe make domestic hot water if you need it to. If you need cooling and it’s 62 or 63 degrees, you can cool with the reserve of chilled water in the buffer tank. By the same token, if you need heating when it’s 54 or 55 degrees, you’ll have heated water in the buffer tank.

And if you have a houseful of people over for a spring holiday and you’re in the dead band, you can go into a forced cooling mode if you want to.

John: Awesomeness! We have two callers on the line now Dave, and both have the same question. Drake from Idaho and Tom from New Hampshire both want to know how an air-to-water heat pump can make domestic hot water when the heat pump itself is in cooling mode.

Caller: Yeah, this is Drake. I’m with that Tom guy. It doesn’t make sense that an air-to-water heat pump can make heated water for the indirect hot water tank and chilled water for cooling at the same time.

Caller: Yeah, this is Drake. I’m with that Tom guy. It doesn’t make sense that an air-to-water heat pump can make heated water for the indirect hot water tank and chilled water for cooling at the same time.

Dave: Great observations guys, and you’re correct. An air-to-water heat pump can’t make heated and chilled water at the same time.

Caller: Yeah, this is Tom. That Drake fellah is wicked smaht to ask that question. How can you make the watah hawtt when the freakin’ heat pump is making cold?

Dave: That’s where a buffer tank becomes really important. Let’s say the heat pump is in cooling made. With System M you’ll have a 30 gallon buffer tank filled with chilled water. When the indirect domestic water heater calls to make more hot water, the heat pump immediately jumps into heating mode.

Since you want to make hot water as quickly as you can, you can’t really wait for the 30 gallons of chilled water to be used up. And we don’t want the heat pump to turn all that chilled water into hot water. It would take forever and it’s not exactly what you’d call “green.”

John: Right you are, Dave. That’s where the piping in the System M indoor unit – what we lovingly refer to as the “HydroBox” – comes in. The piping arrangement in the HydroBox is called – are you ready? – a dual differential pressureless manifold. Its job is to hydraulically separate the heating and cooling piping circuits from the buffer tank-heat pump piping circuits. In addition, it also isolates the indirect DHW tank piping from both the heating and cooling circuits.

Dave: Exactamundo, my man. So when the indirect calls to make DHW, the heat pump itself goes right into heating mode, and the hot water from the heat pump bypasses the buffer tank altogether and goes direct to the indirect. The cooling circuit, meanwhile, can still run using the 30 gallons of chilled water that’s still in the buffer tank.

Caller: But won’t that water heat up quickly?

John: It’ll heat up over time, which means two things. First, the best applications for air-to-water heat pumps are very well insulated homes (think steroidal insulation) that don’t heat up or cool down quickly. That buys you time.

Dave: Additionally, you can program the unit to regenerate the hot water tank at specific times. Maybe the best time to do it during cooling season is at night when you’re asleep. You’ll be less likely to notice any temperature creep.

John: Wow, will you look at that. The old clock on the wall says time is up for this week’s edition of Everything You Always Wanted to Know About Heat Pumps* (*But Were Afraid to Ask). Thanks for being with us.

Dave: And if you enjoyed this show, make sure to join John and myself online during the spring and summer on Taco After Dark, our weekly nighttime program dedicated to all things hydronic, plumbing and heat pumps.

The fun starts once the sun goes down!

In today’s fast-paced world, leveraging the power of online resources is essential for the success of any plumbing contractor. Ferguson.com is that resource. As a busy service contractor, time is of the essence. When I plan out my busy week schedule, resource efficiencies are at a premium, and that includes stocking my truck adequately. Moreover Read more

In today’s fast-paced world, leveraging the power of online resources is essential for the success of any plumbing contractor. Ferguson.com is that resource.

As a busy service contractor, time is of the essence. When I plan out my busy week schedule, resource efficiencies are at a premium, and that includes stocking my truck adequately. Moreover, running a successful plumbing business requires access to quality products, reliable suppliers, and expert advice. In today’s digital age, having a robust online platform can significantly streamline your operations and contribute to your business’s growth.

In today’s post-COVID world, especially dealing with disruptive supply chain issues, it almost goes without saying; you can never have too much inventory on the truck or back at the shop. That’s why I rely on Ferguson.com, a comprehensive website that has plumbing contractor-specific resources available, all of which are literally just a click away. And that click provides real-time stock and pricing of more than 200,000 HVAC and plumbing products; I can see what’s in stock and my contract pricing.

My plumbing business relies on my wholesaler to carry a vast range of top-quality products from leading brands, and I trust Ferguson to provide those trusted, reliable, and durable solutions. Whether I’m looking for pipes, fittings, valves, fixtures, boiler parts or specialty items, I look to Ferguson.com.

Some really helpful features include “My Lists.” I am able to customize the order process with just a few clicks, instead of individually searching for the products I purchase regularly and organizing lists of the products I want. This ultimately has saved me time and has helped to streamline my ordering process. Ferguson.com even gives me the ability to share those lists I’ve created and keeps products I purchase under the “Bought Often” tab, which is automatically updated monthly.

The Quick Tools feature is a shortcut that makes it easy for trade professionals to quickly access other popular site features. It gives me the quick ability to order, reorder, find an order, or turn existing quotes into orders, all in one place. In some cases, I can even order online and have the order ready in an hour with Pro Pick-Up 1 Hour (at locations where Pro Pick-Up 1 Hour is available).

While traditional brick-and-mortar purchasing is still a viable wholesale solution, with Ferguson.com, I can gain access to a seamless and convenient online ordering system. This allows me to browse through products, check availability, compare prices, and place orders anytime, from anywhere. By simplifying the procurement process, Ferguson.com saves valuable time and effort, enabling me to focus on serving my customers better.

Furthermore, as a plumbing contractor, staying up to date with the latest industry trends and techniques is crucial. Ferguson.com offers a wealth of resources and expert advice to help me stay ahead of the curve. From informative articles and how-to guides to videos and product demonstrations, the website serves as a knowledge hub for plumbing professionals. Leveraging this wealth of information can enhance one’s expertise, expand a skill set, and ultimately elevate one’s business.

Furthermore, as a plumbing contractor, staying up to date with the latest industry trends and techniques is crucial. Ferguson.com offers a wealth of resources and expert advice to help me stay ahead of the curve. From informative articles and how-to guides to videos and product demonstrations, the website serves as a knowledge hub for plumbing professionals. Leveraging this wealth of information can enhance one’s expertise, expand a skill set, and ultimately elevate one’s business.

Sometimes I need to know what was on an order or the last time I bought a certain product. I’m able to find all of that online and end any confusion about my orders. If I need to see the status of an order, I can see it on my Ferguson Dashboard or Orders, and even get the proof of delivery. (Proof of delivery may not be available depending on how the order shipped or if it was signed for.)

Forward Thinking

Ferguson understands the importance of competitive pricing for plumbing contractors. By signing up for a Ferguson.com account, one can unlock access to exclusive contractor pricing on a wide range of products. This ensures that I can offer my customers competitive rates while maintaining healthy profit margins for my business. The savings one can achieve through Ferguson.com can significantly impact your bottom line and give you a competitive edge in the market.

It’s pretty simple, really. Creating an account on Ferguson.com provides plumbing contractors with a range of powerful tools to manage their business efficiently. By logging in, one can track his or her order history, access invoices, and manage one’s account settings, all in one centralized location. This streamlined account management feature eliminates the need for tedious paperwork and enables one to stay organized and in control.

What’s also cool about the site is that I can enroll for the free PRO Plus™ program. After I enrolled in this program, I now earn one point for every dollar I spent online. I can then redeem those points for cool prizes and earn Bonus Points faster by purchasing featured products. PRO Plus™ customers are also eligible for discounts with select businesses.

Ferguson.com boasts an extensive inventory of plumbing products, tools, and supplies, as well as expert advice and efficient account management, making it a one-stop solution for all of my business needs. By utilizing the features and capabilities of Ferguson.com, I can streamline my operations, relieve operational stress, and propel my business toward greater success. Sign up today and unlock a world of opportunities for your plumbing contracting business with Ferguson.com.