I know it’s the start of summer and you’re thinking, “who is thinking snow and cold temps?” But it could be the best time to ramp up your snowmelt game for the upcoming winter season. Once upon a time, commercial snowmelt systems lived independently, with little concern about the larger mechanical environment they were often a Read more

Featured Articles

I know it’s the start of summer and you’re thinking, “who is thinking snow and cold temps?” But it could be the best time to ramp up your snowmelt game for the upcoming winter season. Once upon a time, commercial snowmelt systems lived independently, with little concern about the larger mechanical environment they were often a part of. Typically, a boiler provided heat and a smart tubing layout, properly circulated, offered thermal distribution.

Voila! As if by magic, tropical warmth gently melted away midwinter precipitation from parking lots, walkways, ramps and driveways.

All good things change, and occasionally for the better. As for modern snowmelt systems, their renaissance has come in the way of—you probably guessed it— improved and more sophisticated controls. Now, snowmelt systems can integrate with BAS (building automation systems).

It only makes sense that snowmelt systems would eventually cross that bridge. Getting there, however, wasn’t without challenge.

BAS networks, by design, are largely “inclusive.” That is, their purpose in life is to integrate, control and monitor as many of a building’s key functions as possible, including heating, cooling, ventilation, lighting and other important operations.

Yet, because snowmelt systems operate outside a building, and are exposed to ambient conditions outside the envelope—with conditions that change quickly, often requiring far more than simple on/off function—BAS systems are challenged by their limitations. The key frustration expressed by design engineers, installers and building owners alike is that the ever-changing nature of outside, ambient conditions defies the constraints of most automated controls.

For this reason, anyone attempting to tie commercial snowmelt function with a BAS confronted a giant hurdle.

Fortunately, those impediments may now be things of the past.

The nature of the beast

For the longest time, achieving proper connection to and communication between snowmelt controls and a BAS was the seemingly impossible task. The two key parts of that puzzle were a.) sensors didn’t want to communicate digitally with the BAS, and b.) controls were mostly incapable of anything more than on-off operation. Maintaining idle operation, controlling gradual increases in temperature, or especially measured deactivation—these became the key challenges.

After all, if snowmelt system deactivation happens too soon, winter accumulations may pile up, or snow may melt prematurely, turning into treacherous ice. Or, if a system demands too much heat, or stays on too long, it punishes the building owner with unexpected operational costs.

For many years, there were many reverse-engineered attempts to connect snow and ice sensors with building automation systems. However, more recently, new technology has been developed to meet this challenge.

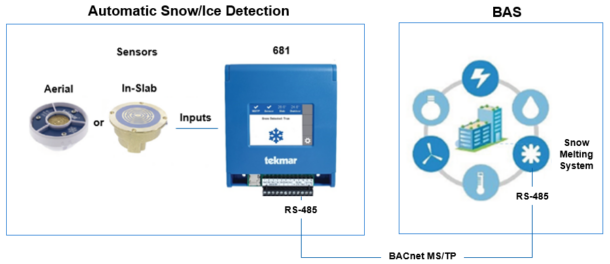

This new technology helps connect these two previously disconnected functions by receiving input data and sending information from sophisticated sensors directly to the building automation system, which ultimately tells the snow melting system to turn on or off.

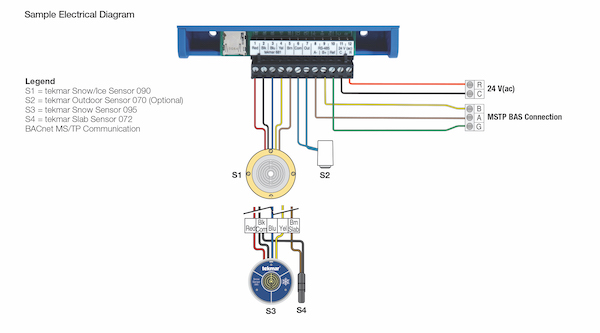

A snow and ice sensor interface communicates directly with a BAS controller through BACnet MS/TP protocol, letting the BAS know to engage the on and off function of a snowmelt system when the outside sensors detect snow or ice. This unique piece of technology has quickly turned a traditionally inefficient process into a smart and truly automated system.

Having the ability to interface snow and ice sensors directly with any BACnet controller is not only creating more efficient snow melting systems for facility and building owners, it’s making it easier for contractors to have a simple, standard solution that can be easily applied to any snowmelt job—without custom coding or complex installation.

Having the ability to interface snow and ice sensors directly with any BACnet controller is not only creating more efficient snow melting systems for facility and building owners, it’s making it easier for contractors to have a simple, standard solution that can be easily applied to any snowmelt job—without custom coding or complex installation.

Despite its simplicity, connecting a snow and ice sensor interface to a BAS should incorporate many functions, also known as objects (see bullets below). The device itself is designed to be installed in a mechanical room, or at any remote location on site—perhaps in a service room closer to the snow melting area.

The list of data objects shared with the BAS controller should ideally include:

- Snow or ice has been detected

- Snow or ice has not been detected

- Outdoor air temperature

- Slab temperature

- Slab target temperature

- Snow/ice sensor sensitivity

- Warm weather shut down (WWSD)

- Cold weather cut off (CWCO)

- Error codes

As is often the case—and especially when new technology is introduced—questions arise. Here are some common questions from professionals in the field:

What happens if ambient conditions are too cold, or too warm?

Interface features such as warm weather shut down (WWSD) and cold weather cut off (CWCO) are particularly useful in ensuring the snow melting system is only running when needed. For instance, with CWCO, when outdoor air temperature is too cold (below CWCO setting), the BAS heat source is not able to increase the slab temperature to melt snow or ice. Features like this create critical efficiencies and save loads of energy.

With the right technology in place, the interface sends a signal to the BAS to turn off the snow melting system. Once the outdoor air temperature increases above the CWCO temperature setpoint, the interface will communicate to the BAS to turn on the snow melting system and resume its operation.

Of course, if conditions are too warm for the formation of snow or ice, the systems will use the opposite logic (WWSD) and tells the BAS to deactivate the system.

What types of alert functions are available to building managers?

Ideally, a snow and ice sensor interface will use error codes to signal the BAS controller if there are operational problems with the sensors.

This would allow the BAS to have feedback on the system and determine if any action needs to be taken.

Can contractors use the BACnet Sensor Interface with any snowmelt application controlled by BAS controllers?

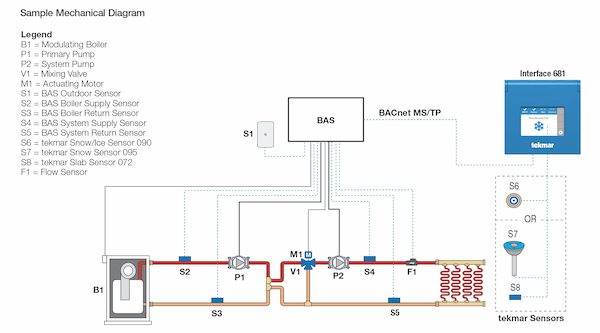

Here, too—a versatile snow and ice sensor interface should be compatible with any snowmelt system application. After all, BAS controllers use BACnet MS/TP protocol for communication. The technology should be capable across many types of installations, such as snowmelt applications with a simple dedicated boiler, or more complex multi-boiler plants with multiple zones and mixing valves. And, the right technology should be BTL certified, providing the confidence of seamless integration.

Here, too—a versatile snow and ice sensor interface should be compatible with any snowmelt system application. After all, BAS controllers use BACnet MS/TP protocol for communication. The technology should be capable across many types of installations, such as snowmelt applications with a simple dedicated boiler, or more complex multi-boiler plants with multiple zones and mixing valves. And, the right technology should be BTL certified, providing the confidence of seamless integration.

Why is it important to control the slab temperature?

Controlling slab temperature is crucial to have an efficient snowmelt system. If the slab temperature is too low, the snow will not melt off. If the temperature is too high, the slab could be damaged and will waste a lot of energy.

Information = power

So, if you’re faced with the need to install—or retrofit—a commercial snowmelt system, and BAS is in the cards, you’re now equipped with new information and ready to reenter winter warfare. But this time, better prepared.

Cleber Alves is product manager for tekmar.

Mechanical Hub continues its conversation regarding heat pumps and heat pump technology. Electrification and carbon reduction is core to the emergence of heat pump technology. We recently spoke with Mark Chaffee, VP Governmental Affairs and Commercial & Industrial Product Management, Taco Comfort Solutions. MH: What are some of the driving forces behind heat pump technology? Chaffee: The Read more

Mechanical Hub continues its conversation regarding heat pumps and heat pump technology. Electrification and carbon reduction is core to the emergence of heat pump technology. We recently spoke with Mark Chaffee, VP Governmental Affairs and Commercial & Industrial Product Management, Taco Comfort Solutions.

Mechanical Hub continues its conversation regarding heat pumps and heat pump technology. Electrification and carbon reduction is core to the emergence of heat pump technology. We recently spoke with Mark Chaffee, VP Governmental Affairs and Commercial & Industrial Product Management, Taco Comfort Solutions.

MH: What are some of the driving forces behind heat pump technology?

Chaffee: The key, driving factor is a desire for CO2 reduction by using less fossil fuel. The world’s leading cultures and political forces have chosen to pursue beneficial electrification as a key component to achieve reduction goals. So, how is it that we can most quickly, substantively reduce our dependence on fossil fuels—a key contributor to carbon emissions? Heat pump technology is the HVAC industry’s best foot forward in achieving this today.

The effort to accomplish decarbonization is broken into two primary camps: a.) at the grid (source) level, and b.) equipment (local).

At the grid level, our 50 states are all at different places in implementing this. And, for the technology that’s involved residentially, and commercially, the ability of heat pumps to deliver COP’s (coefficient of performance) of 3, 4 and 5—meaning operational efficiencies of 300, 400 and 500 percent, or more— can’t be ignored. In comparison, fossil fuel burning equipment can achieve efficiencies of maybe 92 to 98 percent at best.

The goal: clean, efficient grid energy in combination with the highest efficiency HVAC solutions possible. Then install some solar panels on your house or commercial building (distributed green energy) for another win. Heat pumps measure up effectively as viable equipment solutions to keep people comfortable year-round.

MH: What are the benefits of heat pump technology?

Chaffee: At Taco Comfort Solutions, we believe that the best, no-compromise product offering comes from air-to-water systems; we want to be sure they have a seat at the table. They offer extreme energy efficiency, and the finest heating and cooling solutions with the greatest options and flexibility for delivery of that comfort—such as low-temperature radiant heat and towel warmers, etc. And: cooling, too. Hydronic technology is the undisputed king of comfort for humans.

With so many other heat pump technologies (for instance, mini splits, VRF or split system HVAC equipment), refrigerants are the means of thermal exchange across all facets of the distribution network. Refrigerant lines may pierce roofs, and course their way through attics and walls from condensing units to air handlers or terminal units. We prefer the much improved means of using water as the primary source of distribution; it’s safer, less expensive and more efficient. We know water to be the cleanest and most efficient medium of thermal exchange. Simply, more BTUs can be transported by water than by refrigerant compounds or by forced air.

With so many other heat pump technologies (for instance, mini splits, VRF or split system HVAC equipment), refrigerants are the means of thermal exchange across all facets of the distribution network. Refrigerant lines may pierce roofs, and course their way through attics and walls from condensing units to air handlers or terminal units. We prefer the much improved means of using water as the primary source of distribution; it’s safer, less expensive and more efficient. We know water to be the cleanest and most efficient medium of thermal exchange. Simply, more BTUs can be transported by water than by refrigerant compounds or by forced air.

We aren’t comparing heat pumps with boilers here. For generating high temperature water, there’s nothing better than a sturdy boiler. On the other hand, we are comparing air-to-water heat pumps with forced air systems and traditional ground-sourced geothermal systems, the latter of which can also consistently provide efficient, decarbonized comfort, though with substantial up-front costs to accomplish geoexchange.

Air-to-water heat pumps are a viable solution and can deliver no-compromise, year-round comfort without wells, deep and grouted boreholes, trenches, or underwater heat exchangers.

Heat pumps offer extreme efficiency, with heating and colling for year-round comfort. Some of them, like ours, also provide super-efficient heating of domestic water—all from a single appliance-like device.

MH: Do you see demand for Heat pumps more on the residential side than commercial? What’s the ratio?

Chaffee: We’ve all seen the explosive growth of mini-splits in the US residential market. To a large extent, homeowners have accepted and appreciate them. In the commercial sector, VRF technology has also seen broad acceptance, but there’s a tougher battle for dominance of the market—including the hydronic technology that we at Taco have invested in heavily.

Air-to-water systems represent a small percentage of both markets—residential and commercial—though with great potential for growth. After all, their superior comfort and technology offerings is matched with the ability to decarbonize. They can also handle the domestic hot water loads as part of a singular system.

Consider, too, that a lot of refrigerant compounds have come and gone in the last couple of decades. As increased regulatory and environmental efforts removed more from the market, the long-term viability of distributed refrigerant-based systems comes into question. Why rip out and replace an existing system just because refrigerant laws change? Hydronics has always been able to adapt and upgrade to environmental, regulatory or technology changes.

I hope we see a great deal more demand for water-based systems in both the commercial and residential markets to help meet the demands for a low carbon society.

A ratio? Right now, the growth trend is affecting both markets equally, though overall—the residential market has seen faster growth initially.

MH: Can the grid support a HP transition?

Chaffee: Probably not, in its current state. But that won’t stop anyone from trying to achieve 100 percent clean energy. But, there’s a lot of work to be done to improve grid conditions before this can accomplished.

MH: Is a different skill set required for installation?

For the most part—no. Most trade professionals in the market today have everything they need—from expertise on tap, skills and tools—to accomplish proper installation of heat pumps. Those who already have a refrigerant license have a step up. Though, what little refrigerant there is within our System M is fully sealed at the factory in the outdoor unit, so no refrigerant license is needed to install the unit.

There are two types of heat pumps as defined by refrigerant technology:

- Monobloc—all refrigerant and the compressor are within the exterior unit, factory-sealed; refrigerant-to-water is the medium for thermal exchange. Only water moves to and from the exterior unit to the home or business for space conditioning.

- Split—these systems move refrigerant from the outside condensing unit to the inside of a structure in the process of air-to-refrigerant, or refrigerant-to-air thermal exchange.

MH: Life expectancy compared to boilers?

Chaffee: Nothing lasts like a boiler. Though many improvements have been made to boilers through the years, chiefly to enhance efficiency, their ability— by design—to heat water and transport it out for distribution, and then back again, is unsurpassed. In round numbers, a boiler’s lifespan is about 30 years.

Now, consider the rate new HVAC technology introductions over the past decade or so. In that same 30 years, a lot of new technology will emerge to supplant any appliance on the market today, and some will see the influence of refrigerant compounds that will be legislated-out, making them obsolete. It’s become broadly accepted that if an appliance lasts 15 to 20 years, its met its expectation.

Essentially, today’s air-to-water heat pump systems are appliances— considering their construction and durability. With proper installation and routine maintenance, they should last 15 to 20 years.

MH: Will you offer training for these products?

Chaffee: Yes. Taco provides training for all of the technology it offers to the market. We’re passionate about the support we offer to installers and system designers, the System M air-to-water heat pump will allow us to continue to educate on products and system design, especially as we look to implement high performance, energy efficient HVAC system.

MH: Other thoughts?

Chaffee: Glad you asked! We’ve heard this question on many occasions from a wide range of trade professionals: “Why does Taco want to offer this technology?”

The answer stems from our combination of expertise in hydronics, thermal distribution and comfort. These different facets meet and combine uniquely in our newest technology—the System M. It’s a single-source, air-to-water, turnkey heat pump system designed and built to meet the comfort and efficiency needs of a low-carbon society.

If we at Taco can help the trade to accomplish this, all the better. After all, that’s been an important part of our makeup dating back more than 100 years now. In the past decade or so, we’ve made a concerted effort to move from our role as a component manufacturer to that of a systems provider. With System M, we’ve combined no-compromise comfort with environmental benefits. And, considering that the technology is easy to size and install, it’s a win-win from many perspectives.

Like many others in the plumbing industry, Chase Wenger started out on the weekends helping his dad, who is co-owner (with Chase’s uncle) of C.V. Wenger Inc., Chambersburg, Pa. “When I was a kid, I hated cleaning the house so I would leap at any chance to go to work with my dad. We’d stop for Read more

Like many others in the plumbing industry, Chase Wenger started out on the weekends helping his dad, who is co-owner (with Chase’s uncle) of C.V. Wenger Inc., Chambersburg, Pa. “When I was a kid, I hated cleaning the house so I would leap at any chance to go to work with my dad. We’d stop for gas, and he’d buy me a soda and a candy bar, and we’d ride around to jobs and spend the day together,” says Wenger. “Those are some of my fondest memories,” recalls Wenger. “I put my first boiler in with my dad when I was in elementary school, and from that point on I was hooked.”

Chase owes a lot to his dad, uncle and grandfather—who started the company in 1954—who all become mentors in some fashion. “They taught me to do the best I can no matter what, to be resourceful, and to think outside the box, while always encouraging me to learn more,” says Wenger.

In addition, Dan Holohan is a huge mentor for Wenger as well, even if he doesn’t know it. “I recall telling him one time about a steam system I put in from scratch, he shook my hand and told me, ‘Congratulations, that automatically makes you 65 years older kid, great job.’”

Wenger likes to think that that every tradesman he’s ever met/worked with was a mentor, continuously trying to learn something new from everyone he meets. Although he fondly recalls shakily holding the flashlight for his dad as a young boy’s mind wandered around almost as much as the flashlight beam, searching through the truck for the 5th time for that screwdriver he’s sure he left back there. “If you want to keep a kid indisposed for a bit, just assign them a mission they can’t complete if you have that one thing they’re searching for hidden in your toolbox. LOL,” says Wenger.

Wenger likes to think that that every tradesman he’s ever met/worked with was a mentor, continuously trying to learn something new from everyone he meets. Although he fondly recalls shakily holding the flashlight for his dad as a young boy’s mind wandered around almost as much as the flashlight beam, searching through the truck for the 5th time for that screwdriver he’s sure he left back there. “If you want to keep a kid indisposed for a bit, just assign them a mission they can’t complete if you have that one thing they’re searching for hidden in your toolbox. LOL,” says Wenger.

Moving on Up

Chase made his way to washing trucks and stocking shelves, eventually moving on to help with installs. Then one especially busy day, a lead guy didn’t come to work. “I was instantly upgraded to a full-fledged tech/plumber. As I learned more, I decided I needed to get my Masters Plumber License. From that point on, I started to design my own systems in addition to installing them,” says Wenger.

And while Wenger’s official title of Supervisor/Lead Field Foreman has him lead larger projects—from commercial to residential—from both installation and service work, as well as troubleshooting and tech support roles for other technicians, one of the most rewarding things to me is helping out someone in need, whether it’s replacing a broken well pump, resolving his/her water quality problems or restoring a customer’s heat in the dead of winter. “Although, making a customer’s dirty, brown-stained, sulfur-smelling water into delicious crystal clear water is especially satisfying for me,” says Wenger.

And while Wenger’s official title of Supervisor/Lead Field Foreman has him lead larger projects—from commercial to residential—from both installation and service work, as well as troubleshooting and tech support roles for other technicians, one of the most rewarding things to me is helping out someone in need, whether it’s replacing a broken well pump, resolving his/her water quality problems or restoring a customer’s heat in the dead of winter. “Although, making a customer’s dirty, brown-stained, sulfur-smelling water into delicious crystal clear water is especially satisfying for me,” says Wenger.

Wenger also enjoys replacing old worn-out systems—wells, water systems, drainage systems, heating/air conditioner systems, etc.—with new efficient ones while cleaning them up and generally making them better all around.

Wenger’s main specialty is well pumps, water treatment, excavation, in addition to regular service/install work with anything the company offers. Oh, and by the way, Wenger is also a licensed Master Electrician, HVAC tech, and he runs a sheet metal shop.

Wenger’s main specialty is well pumps, water treatment, excavation, in addition to regular service/install work with anything the company offers. Oh, and by the way, Wenger is also a licensed Master Electrician, HVAC tech, and he runs a sheet metal shop.

But with all hard work comes some play time, right? “It’s always a tricky balance, but you just need to set specific boundaries and make time to do the things you want to do.” For Wenger, kayaking, reading, spending time with my family and friends is time well spent. A bucket list item? “Definitely kayaking over more waterfalls, or trying wing-suiting in Scandinavia.

Moving the Industry Forward

Moving forward, the industry needs to continue to eliminate the stereotype of the plumber as an unclean, uneducated worker would be a good start, says Wenger. Also, “We need to showcase how rewarding/satisfying the profession/industry is, offering education/training. A lot of people dislike working on things that they don’t completely understand, and paying them what they’re worth,” says Wenger.

Social media has helped the trades’ image problem. “It’s definitely helped me meet others in the trade, well beyond my regular service area,” says Wenger. “I’ve learned a lot from seeing how others do things and talking with them. I like to think everyone can teach you something in life—even if it’s simply what not to do.”

In the end, it’s about passing the torch. “I tend to forget that I’m not the new guy anymore, even after 15 years. I certainly hope I can be a role model for others both in the trade, and those considering joining this marvelous trade, and any other trade out there. It’s a wonderful career to have,” says Wenger.

According to a recent study by Global Market Insights, the air source heat pump market value is projected to cross $77 billion by 2028. Increasing demand from growing real estate sector along with soaring requirement of space heating applications across colder regions will encourage the product deployment. Air to water source heat pumps segment is Read more

According to a recent study by Global Market Insights, the air source heat pump market value is projected to cross $77 billion by 2028. Increasing demand from growing real estate sector along with soaring requirement of space heating applications across colder regions will encourage the product deployment.

Air to water source heat pumps segment is anticipated to witness a noteworthy growth owing to various features including simple design and easy installation, says the report. Rising global temperature and growing green building construction will provide positive drivers for product deployment. Integration with solar heating source and hence low input cost for product across temperate countries will drive the space heating systems demand in the forecast timeline.

Lochinvar’s air source heat pump water heater

The movement towards electrification—moving away from fossil fuel—seems to be the main driver of the heat pump movement. “I think consumers see an option to add PV, or join a solar garden, to become more energy independent. So having a heating, cooling and DHW option powered by your roof makes some sense. The rise in fossil fuel prices, uncertainty around supply certainly adds some motivation to look at heat pumps,” says Bob ‘Hot Rod’ Rohr, training manager, Caleffi, and former hydronic contractor of more than 30 years.

Recently, Mechanical Hub spoke with Arthur Smith, Residential Product Manager, A. O. Smith, and Jennifer Russell, Segment Development Manager, Decarbonization, Lochinvar, to get the latest on heat pump technology and heat pumps water heaters.

MH: What are some of the driving forces behind this technology?

Arthur: At A. O. Smith, we’ve seen two major driving factors behind the increasing popularity of residential heat pump water heaters. First, as consumers have begun to see wider availability of this technology, along with its carbon emissions reduction and tremendous cost savings, they’ve pushed to utilize heat pump water heaters in their own homes, further increasing demand. The second driving factor we’ve seen is the evolving regulations around decarbonization. These changes have placed an emphasis on heat pump technology as an excellent option for greenhouse gas reduction.

A. O. Smith’s CHP-120 heat pump water heater

Jennifer: On the commercial side, greenhouse gas emission reduction is the main driving force behind the increase and development of heat pump technology. However, due to the lack of availability of commercial heat pump technology, we don’t see it utilized in applications as often as the residential sector. In addition to state and local reduction goals, there are also many companies and building owners who are setting their own goals for reducing greenhouse gas emissions and they’re seeking out heat pump water heaters as a way to meet those goals.

MH: What are the benefits of heat pump technology?

Arthur: The core benefit of heat pump water heaters is the massive jump in efficiency. High efficiencies drive cost savings, which is a huge benefit to homeowners.

Jennifer: One of the main benefits of heat pump technology is that there are zero direct carbon emissions from the unit. For any commercial building looking to decrease its environmental impact footprint, this technology can play a big role in meeting those goals. In addition to the environmental benefits, heat pump technology is also incredibly efficient, providing an average annual efficiency of 200-300%.

MH: Do you see demand for heat pumps more on the residential side than commercial? What is the ratio?

Arthur: Overall, we’ve seen significant interest in both commercial and residential applications.

Jennifer: At Lochinvar, we’ve seen interest in both commercial and residential applications. Interest in ommercial applications for heat pump water heaters has grown significantly in the last couple of years, primarily due to evolving state and local environmental regulations.

Can the grid support a heat pump transition?

Arthur: The grid has been able to support the transition so far, but as heat pump technology continues to increase in popularity, developing the grid will need to be prioritized. It seems that most regulators are aware of this need to develop the grid and are building their regulations accordingly so the grid isn’t overwhelmed.

Jennifer: While the grid may be able to support a heat pump transition eventually, it can’t happen overnight. It’s going to take many years to fully develop a grid that can support a full transition to heat pump technology. In the meantime, we can develop and implement tools, such as demand-response technology, to help support the transition.

Commercial Heat Pump Water Heater

MH: Is a different skill set required for installation?

Arthur: On the residential side, there isn’t a different skill set required for installation. A. O. Smith designed our residential heat pumps so they can be installed in almost the same way as our standard electric water heaters. There are still some minor considerations, like draining non-acidic condensate produced by heat pumps and differing space requirements, but overall, the installation process is nearly the same as what most contractors are familiar with now.

Jennifer: There isn’t a different skill set required for installation, but there is unique training that can better prepare someone to install or service heat pumps. Heat pump water heaters have features that differ from traditional water heaters and these features require different training. Lochinvar offers training to help educate on the unique application features of heat pump technology.

MH: What is the life expectancy compared to boilers?

Arthur: Our heat pump water heaters are built to the same quality standards as all A. O. Smith products. We put care into developing products that perform well throughout their lifetime. We’re confident in our products and offer a standard 10-year limited warranty on every heat pump we produce.

Jennifer: You’re not going to see any loss of life expectancy with heat pump water heaters. They’re designed to hold up and perform as well as other water heating technology

MH: Do you offer training for these products?

Arthur: Since residential heat pump technology has been around for a bit longer than commercial, we’ve had time to develop training resources that focus on the installation and servicing of these units. A. O. Smith University offers digital live training at www.university.hotwater.com and there are courses available that focus specifically on heat pump technology.

Jennifer: At Lochinvar, we offer training resources to educate sales reps, engineers, contractors and technicians on heat pump technology. At the moment, our heat pump training focuses on topics such as applications for heat pumps, ensuring the correct unit size specification and understanding the technology’s benefits and features.

Hunting is a lot like many outdoor pursuits in that you can’t control the weather. Hunting guides and outfitters also know that you can’t control the animals, so they control what variables they can: the food and the lodging. Fred and Michele Eichler operate Fulldraw Outfitters in southern Colorado where they host hunters looking to Read more

Hunting is a lot like many outdoor pursuits in that you can’t control the weather. Hunting guides and outfitters also know that you can’t control the animals, so they control what variables they can: the food and the lodging.

Fred and Michele Eichler operate Fulldraw Outfitters in southern Colorado where they host hunters looking to harvest elk, deer, bear, antelope and turkey in fair-chase pursuit.

Fred, arguably one of the greatest bow hunters alive today, became the first person to harvest all 29 North American big game species with a recurve bow, completing his Super Slam. Michele, who’s also been a bow hunter since childhood, was CEO of Muzzy Products, an archery brand that all bow hunters in the country are familiar with.

(L-R) Michele Eichler, Steve Fernandez, Ty Fernandez, Federico Orozco.

The hunting on the properties where the Eichlers outfit is exceptional, and the accommodations have always been very good, but in early 2020 the family made a decision to raise the stakes. They wanted to build a new lodge to host guests, with all the amenities that a professional hunting outfit might need – 11 bedrooms, a walk-in cooler for game, vaulted ceilings for hanging trophies, entertainment space and a giant kitchen complete with two expansive hardwood islands.

Michele designed the lodge with comfort and environmental sustainability in mind. The dream materialized over the course of two years. After ordering the steel frame building, the Eichlers called Steve Fernandez, owner of Twin Peaks Plumbing & Hydronics, in Trinidad, CO. Fernandez is also a very successful big game hunting guide and has known the Eichlers for decades.

“Steve was one of the first people we called,” said Michele. “He quickly suggested using spray foam to insulate the whole building, and to install an in-floor heating system. We hired him for both the plumbing and heating work.”

Twin Peaks, a six-person company, has a fantastic reputation in the Spanish Peaks area of Colorado. Steve’s son, Ty, is the fourth generation plumber in the family.

Twin Peaks plumber Ty Fernandez prepares to head to Eichler’s lodge.

Simple radiant, outstanding comfort

Trinidad might be close to the New Mexico border, but its elevation of 6,000 feet above sea level means that the region sees serious winter conditions. Temperatures can plunge as low as -20°F.

The 6,000 square foot building – not including the offices, gym and storage space on the second story – is divided into six zones. The entire space is heated from below with half-inch MrPEX oxygen barrier tubing, with the exception of the 225 square foot walk-in cooler. This portion of the slab is isolated from the rest of the polished concrete slab with the same two-inch rigid foam used beneath the pour.

Heat is provided by a propane-fired, 96 percent efficient Aspen condensing boiler, made by U.S. Boiler Company. Fernandez prefers the firetube Aspen over other modulating boilers because it’s easy to program and even easier to service.

Steve Fernandez, owner of Twin Peaks Pluming & Hydronics programs the 270 MBH Aspen condensing boiler.

“We have 30 or more Aspen boilers in the field, all of them at high altitude,” said Fernandez. “Their design is so intuitive that my apprentices have caught onto them very quickly.”

Most of the 20 loops in the slab enter the main mechanical room, but Twin Peaks placed two, three-quarter-inch remote manifolds at either end of the 100-foot-long long building. Each zone is circulated by a Taco 007e ECM pump. With outdoor reset and a maximum supply temperature set at 130°F, the system provides a 12°F Delta-T.

“Our loops here are all between 280 and 290 feet long, so there was no need to use balancing manifolds,” said Fernandez. “The ports on balancing manifolds severely raise head pressure by constricting flow, especially with a high glycol mixture. We isolate all our loops with ball valves to help purge the system. That said, there are times I feel balancing manifolds are necessary, especially when we didn’t install the tubing and we have no idea what’s under the slab.”

Before firing the system, Fernandez injected the radiant system with Fernox F1 Protector. This helps guard system components against the low pH water and high hardness common to Colorado and other parts of the Southwest. To provide burst protection down to -20°F, Twin peaks used Fernox Alphi-11 antifreeze.

The system, which covers two diamond-plate aluminum walls, also incorporates Taco’s Near Boiler Trim Kit. This includes air separation, an expansion tank, combination backflow preventer and boiler feed valve, and the brass fittings needed to assemble the components.

Steve Fernandez connects a Taco SmartPlug domestic hot water control for the recirculation loop.

Conserving water, ensuring supply

Fernandez installed the largest of the wall-hung Aspens available, 270 MBH, mainly to handle the massive DHW load. The Aspen is also available in 320 and 399 MBH floor-mounted light commercial sizes, but with the 75-gallon indirect fired water heater installed at Eichler’s, the extra boiler capacity wasn’t needed.

The home’s domestic hot water load is comprised of five bathrooms, a large laundry, kitchen, commercial pot filler and wash-down hoses in the game processing area.

“The amount of laundry my boys create is unbelievable,” said Michele. “When the lodge is full, hunters all come back at roughly the same time, expecting hot showers, a meal, and likely game to process. I told Steve that I never wanted to run out of hot water.”

The floorplan made the use of a domestic hot water circulation system an easy decision. Twin Peaks installed a three-quarter-inch recirculation line, with a stainless steel Taco 006e3 circulator set on medium, plugged into a SmartPlug instant hot water control. Using a temperature sensor that mounts to the hot water supply pipe, the control monitors water use patterns in the home and runs accordingly; no programming, timers or aquastat required.

The large indirect water heater, set to priority, is maintained at 170°F. Water is then mixed down to 135°F before entering the recirculation loop.

“We had 20 guests here at one point and never ran out of hot water,” said Michele. “Hot water arrives immediately at any tap in the lodge. There’s no fresh water being wasted. It actually took a bit of getting used to, after years of waiting for hot water to arrive at a tap.”

The in-floor hydronic system at Eichler’s lodge features a condensing boiler, ECM circulators, a 75-gallon indirect fired water heater and a large DW recirculation loop.

Stewardship

The lodge was occupied in March of 2022 and the Eichlers hosted turkey hunters the next month.

“The heating system has been amazing,” said Michele. “The floors are warm, everything is comfortable, and this building makes a big difference for our guests, Fred, the boys and myself. We have the space to be organized, entertain, and be the best hosts we can.”

From an energy and water conservation perspective, the new lodge demonstrates Fulldraw Outfitters’ environmental responsibility.

The lodge is designed to host and entertain numerous hunting parties at a time.

“Few non-hunters know it, and anti-hunters won’t admit it, but the vast majority of conservation dollars in the United States are raised by hunters,” said Fernandez. “Whether those funds are used for research to combat wildlife sicknesses like Chronic Wasting Disease, improve and protect wildlife habitat, or re-establish wildlife populations, such as we’re seeing with Bighorn Sheep today, the work is largely funded by, and depends on volunteer manpower of, American sportsmen and sportswomen.”

“As hunters, we’re more invested in the health of wildlife populations and preservation of the places they call home than anyone else,” he added.

By reducing their carbon footprint, selecting high-efficiency products and water-saving technologies, and using as many renewable building materials as was feasible, Fred and Michele Eichler have continued to demonstrate their commitment to conservation.