For a boiler to operate properly, the liquid it contains must maintain the correct pH levels. If the pH level is not regularly tested and properly maintained, minerals can build up on the inside of the components. Or the water can turn acidic and attack the boiler’s metallic components and piping from the inside out Read more

Hydronics

For a boiler to operate properly, the liquid it contains must maintain the correct pH levels. If the pH level is not regularly tested and properly maintained, minerals can build up on the inside of the components. Or the water can turn acidic and attack the boiler’s metallic components and piping from the inside out, causing rust to form.

Scale or rust buildup reduces system performance over time. Enough buildup can essentially stop the operation of the system altogether.

Understanding pH levels in hydronic heating systems

Historically denoting “potential of hydrogen,” pH is the measure of how acidic or basic the water inside a hydronic heating system is. According to usgs.gov, the universal reading for pH goes from 0-14, with 7 being neutral. Less than 7 indicates acidity; greater than 7 indicates a base.

- Examples of items that have a pH of less than 7 are black coffee (pH=5), grapefruit juice, soda, or tomato juice (2.5-3.5), and lemon juice or vinegar (2).

- Examples of items that have a pH of greater than 7 would be seawater (8), baking soda (9.5), ammonia solution (10.5-11.5), and liquid drain cleaner (14).

pH is an important indicator of water that is changing chemically. Boiler systems need to have the perfect pH level balance. If the pH goes too high or too low, it can drastically impact a system.

The correct pH level will depend on the metallic composition of the heat exchanger. Some recommended pH levels range from 8 to 8.5. We recommend checking the boiler installation and operation manual to determine the acceptable pH range. Systems with a cast iron, stainless steel or copper exchanger are resilient and usually have a wide range of acceptable levels. Aluminum is more prone to corrosion and may require a specific pH.

Performing pH testing

Do a visual reading by opening the drain valve and bleeding off some liquid. If it appears clear, proceed with a pH test. As mentioned above, the correct pH level depends on the composition of the heat exchanger.

-

How to test pH levels

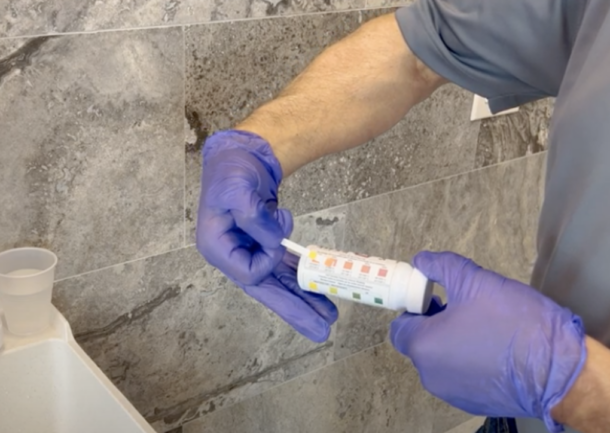

You can buy test strips that provide a color-coded readout. If you need a more precise reading for an aluminum system, use a digital pH meter.

Hercules Cryo-Tek Test Strips, available in packs of 6 to 10 color-coded and disposable test strips, can simultaneously check both the level of freeze protection (propylene glycol) and the level of corrosion protection in a system.

To conduct the test, drain some water from the boiler and then dip one of the pH test strips into the sample. Once a bit of color starts to pop up, compare the strip to the color chart to determine the pH level.

-

How often should you test pH levels?

These are closed systems, so there are usually no external signs of corrosion, making it difficult to spot an equipment leak — unless, of course, water is visibly running onto the floor. (If so, corrosive water inside the boiler is a likely cause.)

This general lack of immediate visibility is why it’s important to test hydronic systems annually. If your locale has hard water or there are conditions causing the water to be more acidic, testing should be done twice a year.

The lack of visibility is also why sampling the water for a test, as described above, is a must: It is the best way to tell if anything is wrong. If rust or sludge appears in your sample, you should test and replace the water.

-

What happens if a boiler’s pH is too high or too low?

If you find the pH levels too high, you’ll start to notice scale or limescale buildup in the boilers. Too much mineral buildup will restrict the system’s water flow. Essentially, the effectiveness of the boiler is lessened.

If the pH levels are too low, the water has turned acidic. This leads to rust and corrosion — a serious problem since boilers are typically made of copper, cast iron, and aluminum. As mentioned earlier, enough corrosion can stop system operation altogether.

-

How to balance out the pH

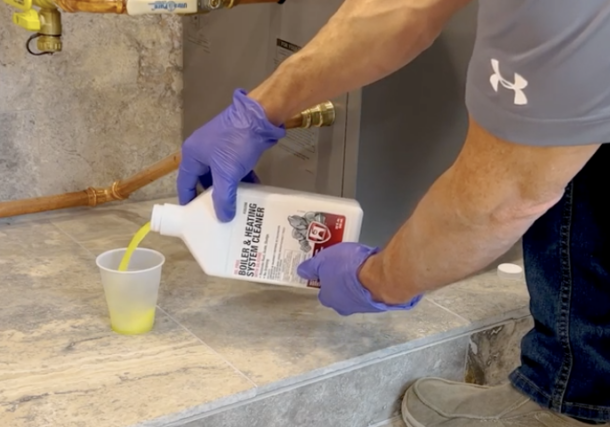

Maintenance managers or contractors can use a corrosion inhibitor to balance out the pH — a seamless fix. However, if the buildup or corrosion has been going on for several years, the system will probably not recover with this treatment. Instead, you’ll have to use a cleaner to flush the system to maximize boiler efficiency.

The Hercules® Boiler and Heating System Cleaner is formulated to clean and condition both steam and hot-water hydronic systems by removing rust, scale, and sludge. The cleaner can also free and lubricate zone valves and help stop priming and foaming with a special anti-foam agent. Ultimately, it is a liquid cleaner and corrosion-prevention treatment.

The Hercules® Sludgehammer System Restorer & Noise Reducer is another option for maintaining a boiler system. More aggressive than the system cleaner, it also cleans and reduces kettling (bubbling and banging), while restoring system efficiency. Maintenance managers or contractors can pair this product with a corrosion inhibitor for annual heating system-maintenance checks.

If the pH level is off:

- Drain about a gallon of liquid from the boiler and dispose of it.

- Fill a container with a quart of corrosion inhibitor, such as Hercules® Sludgehammer™ Universal Corrosion Inhibitor, and 3 quarts of fresh water. Pump it back into the system and allow it to circulate for about a half-an-hour.

- Test again. Usually, a single dose of inhibitor does the job, but if the reading is still too low, repeat the process

Watch the video below to learn how to remove sludge and corrosion in hydronic heating systems with Sludgehammer.

In conclusion, you must test the pH of boiler systems to maximize their efficiency, using products that can make monitoring pH levels simple and easy. If this testing uncovers damage to the system, there are also ways to alleviate and fix that damage.

But regardless of your boiler’s condition, Oatey products can offer a solution. For more information, go to Oatey.com for their heating chemicals and antifreeze products/resources.

Author’s biography: Sean Comerford is a Technical Applications Manager at Oatey Co. He is a third-generation tradesman with nearly 20 years of plumbing experience, including serving as the lead plumber for commercial/residential new-construction, service and fire protection jobs. He holds a State of Ohio Fire Protection License for Sprinkler and Standpipe.

Author’s biography: Sean Comerford is a Technical Applications Manager at Oatey Co. He is a third-generation tradesman with nearly 20 years of plumbing experience, including serving as the lead plumber for commercial/residential new-construction, service and fire protection jobs. He holds a State of Ohio Fire Protection License for Sprinkler and Standpipe.

Our complimentary educational series, Coffee with Caleffi™, is an online technical training webinar and is intended for contractors, designers and wholesalers. What’s next? Maintaining High Fluid Quality in Modern Hydronic Systems (Part 2) Thursday, April 27 12 noon – 1:00pm CDT Fluid problems can cause loss of efficiency, comfort fall-off and/or premature equipment failure. This Read more

Our complimentary educational series, Coffee with Caleffi™, is an online technical training webinar and is intended for contractors, designers and wholesalers.

What’s next?

Maintaining High Fluid Quality in Modern Hydronic Systems (Part 2)

Thursday, April 27

12 noon – 1:00pm CDT

Fluid problems can cause loss of efficiency, comfort fall-off and/or premature equipment failure. This webinar picks up where Part 1 left off (refer to: Maintaining High Fluid Quality, February 2017 in our online archive). Bob “Hot Rod” Rohr, our training and education manager, will focus on glycol systems, sediment formation and fluid quality measurement instruments. You’ll learn:

→ Is municipally treated water good enough for my system?

→ What can cause glycol to degrade over time?

→ Is using only the minimum glycol needed for freeze protection the only factor to consider?

→ Why is the TDS reading of a glycol fluid a meaningless value?

→ Does a pH value within the glycol manufacturer’s acceptable range ensure freeze protection?

→ Low hardness but high TDS. Is my fill water good?

→ My system water is slightly grey. I’m good right?

→ What are some potential mistakes in measuring pH, TDS, hardness or freeze point?

For over 30 years Hot Rod has installed plumbing, radiant heat and renewable energy jobs. As a regular contributor for several industry publications, he puts his rubber-to-the-road experiences to pen. A familiar and favorite speaker at our Coffee with Caleffi webinars, he is sure to delight with his expertise and quick wit.

A Certificate of Participation is emailed to all attendees following the webinar.

All Coffee with Caleffi webinars are free, but registration is required. After registering, you will be immediately forwarded a confirming email containing login details for attending the webinar. When training time comes, grab a coffee, tune in and learn more about Caleffi’s innovative products and how they can add value to your work.

Energy-efficient, reliable, space-saving unit features leading-edge condensing technology for residential applications Burr Ridge, Ill. – Weil-McLain® introduces the new AquaBalance™ combination boiler featuring leading-edge hydronic technology for smaller space residential applications. The state-of-the-art unit combines the warmth of high-efficiency space heating and the convenience of on-demand domestic hot water in a reliable, space-saving, easy-to-install package Read more

Energy-efficient, reliable, space-saving unit features leading-edge

condensing technology for residential applications

Burr Ridge, Ill. – Weil-McLain® introduces the new AquaBalance™ combination boiler featuring leading-edge hydronic technology for smaller space residential applications. The state-of-the-art unit combines the warmth of high-efficiency space heating and the convenience of on-demand domestic hot water in a reliable, space-saving, easy-to-install package.

With a capacity of 155,000 BTUH input, the AquaBalance combi-boiler produces a constant supply of hot water with up to four gallons per minute (GPM) at 70 degrees F. temperature rise.

Featuring 94.4% AFUE energy efficiency, and the industry’s latest stainless steel, titanium-infused heat exchanger technology, the AquaBalance is ENERGY STAR®-rated to deliver maximum operational cost savings to homeowners and provide qualification for local utility rebates, if available.

The unit is ideal for retrofits or new construction in single-family homes, apartments or condominiums.

“The AquaBalance has a wide range of advanced features to deliver energy efficient, worry-free space heat and domestic hot water in a sleek, compact design that’s small enough to fit in a closet,” said Mike Boyd, product manager with Weil-McLain. “The unit’s high-efficiency condensing technology has the power to supply hydronic heat for up to a 2,500 square-foot home and enough hot water to run two showers and a dishwasher simultaneously.”

The combination boiler features an aesthetically pleasing design and simple, user-friendly controls to make installation and operation easy for contractors and homeowners.

“The AquaBalance unit also streamlines the installation process as it eliminates the need to hook up a separate boiler and hot water tank,” said Boyd. “Fewer pipes and less connection points translate into reduced set up time and a more efficient installation.”

Other features of the AquaBalance include:

· Low NOx rated – low emissions level achieved South Coast certification

· Proven Honeywell® boiler controls with digital display

· Unique 3-in-1 vent adapter approved to accept PVC, CPVC, stainless steel or polypropylene vent materials

· Easy electrical connection points and plug in cord

· Heavy gauge insulated jacket for quiet operation

· Removable sides for easy service

· Available as natural gas or propane (LP) gas operation with conversion kit

The AquaBalance joins the Weil-McLain family of boilers that includes the industry’s widest selection of high-efficiency gas and oil-fired boilers for residential and commercial needs.

To learn more about the AquaBalance boiler, visit http://www.AquaBalanceboiler.com or contact a Weil-McLain regional sales office at www.weil-mclain.com/en/weil-mclain/about-us/locations/.

We hear the phrase that water is the universal solvent. Why? So many materials dissolve in water due to its unique molecular structure. So it does not seem like a fluid to be used in a hydronic heating system made of many different materials. Water does have many advantages as a heat transfer material. It Read more

We hear the phrase that water is the universal solvent. Why? So many materials dissolve in water due to its unique molecular structure. So it does not seem like a fluid to be used in a hydronic heating system made of many different materials. Water does have many advantages as a heat transfer material. It is cheap, safe, easily acquired, has a wide liquid temperature range, and is generally non-toxic.

With water coming from so many different sources worldwide, it can contain many different minerals. It is the wide combination of these minerals that water gathers as it flows through our aquifers that needs attention.

Many of the common minerals found in water will cause issues in hydronic systems. The hardness of the water, and minerals that fall from solution, are the most common concerns. As the minerals precipitate out, they can stick to and coat the surfaces of our boiler heat exchangers, for example. This coating forms until enough build-up reduces the heat exchange and the metal of the heat exchanger breaks down. A classic example is what you see when you drain an old tank-style water heater. Some of the material that can be found in tap water cause further concern…like chlorides.

Boiler and tank manufacturers are now listing the most harmful minerals as well as acceptable levels. Calcium, magnesium, chlorides, and sulfates are commonly listed. The ph level is also required to fall within a range, something like 6.6 and 8.5 according to one boiler specification.

Failure to maintain the proper water chemistry can cause loss of efficiency, noise, wear, premature failure, and most important to the consumer, lack of warranty.

So the industry needs to first get some training on what to look for, how to measure levels, and what to do with water that does not meet the quality required to assure warranty coverage.

Most agree that starting with good quality water is one key. It is possible that the water in your town is of sufficient quality. But if you are not testing, you are guessing. Know also that water quality in an area can vary season to season. One of the most noticeable changes in water quality can be linked to the road deicing chemicals used. Back in the day, rock salt, maybe blended with sand, was the go to deicer. Nowadays chloride blends are being used in may states. Chlorides have a wider melt range, and can be applied as a liquid. They often get applied before a snowstorm, or icing condition as a proactive measure.

Guess where these chlorides end up? In our water supplies, via lakes, rivers, and even well sources. Many water sources have been seeing a spike in chlorides. States like Wisconsin and Minnesota have been monitoring this carefully as the aquatic life in their thousands of lakes and rivers are being affected by the elevated chlorides, as well as the flora and fauna.

There is a fairly simple fix for water that is not of sufficient quality for use in hydronic systems. Both deionizing and chemical treatments are available to help bring water back to a hydronic-friendly heat transfer fluid.

Flush your systems. Consider a hydronic detergent to rid the system of oil, flux, dirt, etc. Test the water for the final fill, and treat as required, or haul quality water from another source.

You will be hearing more about boiler water quality as manufacturers of boilers, tanks, pumps, valves, etc. start reexamining warranty returns that have been compromised by fluid quality. It will be a tough conversation to have with a home or building owner if an expensive component fails prematurely due to fluid quality and the warranty is refused.

Hot Rod is currently the training and education manager for Caleffi North America. He owned his own contracting company, Show Me Radiant Heat & Solar, Rogersville, Mo., having been a plumbing and heating contractor since 1978.

Hot Rod is currently the training and education manager for Caleffi North America. He owned his own contracting company, Show Me Radiant Heat & Solar, Rogersville, Mo., having been a plumbing and heating contractor since 1978.

Lochinvar Celebrates 30yrs of Power-Fin® Commercial Product Line The pioneer product of efficient heating experiences a milestone in July 2016 Tennessee-based Lochinvar, LLC is celebrating the 30th anniversary of its industry-changing Power-Fin product line this July. “As a company, we are proud to celebrate the 30th Anniversary of the Power-Fin product line. This product line Read more

Lochinvar Celebrates 30yrs of Power-Fin® Commercial Product Line

The pioneer product of efficient heating experiences a milestone in July 2016

Tennessee-based Lochinvar, LLC is celebrating the 30th anniversary of its industry-changing Power-Fin product line this July.

“As a company, we are proud to celebrate the 30th Anniversary of the Power-Fin product line. This product line transformed the industry and elevated Lochinvar into a leadership position,” said Mike Lahti, vice president of sales, marketing and business development. “Our industry has seen a lot of change over the last 30 years, and at the time of its introduction, the Power-Fin product established a new standard of performance and design.”

Developed in 1986 from Lochinvar pioneer William Vallett Sr.’s vision for a high-efficiency water heater and boiler, the Power-Fin product was the first of its kind and remains the model of efficiency today. With four original models ranging from 250,000 to 1,000,000 Btu/hr., it hit the mark in an industry hungry for high efficiency products. The Power-Fin series was the first commercial product to offer a variety of new technologies and features including:

- Direct vent sealed combustion technology

- Self-diagnostic, removable panel

- Multiple venting options

- Copper-finned, vertical heat exchanger

- Low-mass with a small footprint

- Only boiler in its class that was able to fit through a 36-inch door

“The Power-Fin products created consumer demand and acted as a catalyst for the company’s growth in the 80’s and 90’s which prompted the move to our state-of-the-art new headquarters in 2001,” says William Vallett, Jr., chief executive officer. “Lochinvar’s leadership position in the commercial water heater and boiler business was rooted in the success of the Power-Fin product line.”

The original Power-Fin series played a role in heating water for applications such as nursing homes, restaurants, schools and more. The unique features of the product allowed for the installation of a gas appliance in an area where traditional gas appliances may not be installed due to space constraints in the building.

“Starting with the Power-Fin product line in 1986, we were able to provide something that other companies weren’t focused on, efficiency and footprint,” says Dan Sheko, national sales manager. “Now, 30 years later, we are proud to have continued that tradition and provide some of the highest efficiency products on the market.”

The Power-Fin product was the first to commercialize fan-assisted technology and to this day, still impacts the way engineers think about venting, gas pressure and volume. Lochinvar’s Power-Fin line revolutionized both Lochinvar as a company and the industry as a whole. At the time of its creation, Lochinvar had approximately 30 employees, four of whom are still with the company.

Thirty years since its creation, the Power-Fin product remains one of Lochinvar’s best-selling items. The product continues to evolve, with new “Built-in Advantages,” including expanded burner modulation and the advanced SMART SYSTEM™ operating control. Look for a new Power-Fin product line announcement coming soon.