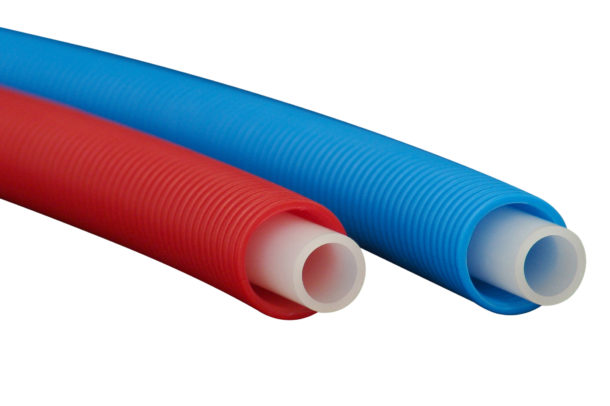

Running pre-sleeved Uponor AquaPEX® in the slab or under the slab can save you significant time and money on your installs. Pre-sleeved PEX pipe does not require insulation, eliminating the added time and costs of insulating a piping system. Additionally, going in or under the slab completely eliminates the need for any hangers or supports Read more

Product Spotlight

Running pre-sleeved Uponor AquaPEX® in the slab or under the slab can save you significant time and money on your installs. Pre-sleeved PEX pipe does not require insulation, eliminating the added time and costs of insulating a piping system. Additionally, going in or under the slab completely eliminates the need for any hangers or supports. And because pre-sleeved Uponor AquaPEX is available in long, flexible coils, it can eliminate underground connections to make installs faster and easier while also further reducing material usage.

Installing plumbing lines in or under the slab provides better performance for the end-user as well. In-slab or under-slab plumbing systems require shorter pipe runs for less water volume in the system. This results in less water waste, less energy usage to heat the water, and better hot-water delivery times.

When it comes to end-user safety, pre-sleeved Uponor AquaPEX is also a best-in-class solution. Because in-slab systems use shorter runs of pipe, it reduces the time water in the pipe spends in the optimal bacterial grow zone of 95°F to 115°F. Additionally, the shorter pipe runs provide better pressure to the fixtures for higher velocity to minimize biofilm attachment and growth, especially compared to metallic piping systems.

San Francisco, 2018 install with in-slab, pre-sleeved PEX

Best of all, you get the confidence that comes with every Uponor AquaPEX plumbing system, including resistance to corrosion, pitting, and scale buildup, flexibility for greater freeze resistance, and the strongest, most reliable connection with the ProPEX® expansion system — all backed by a 25-year transferable limited warranty.

See how Uponor can move your projects forward at uponor-usa.com.

Responding to demand from the trade, NeutraSafe Corporation has begun offering their NSP-50 condensate pump base as a stand-alone product. The patent-pending base, which includes a tray and see-through lid containing NeutraSafe’s proprietary neutralization media sack, is an integral part of the NeutraSafe NSP-50 condensate neutralizing pump. This unit provides condensate neutralization and disposal for Read more

Responding to demand from the trade, NeutraSafe Corporation has begun offering their NSP-50 condensate pump base as a stand-alone product.

Responding to demand from the trade, NeutraSafe Corporation has begun offering their NSP-50 condensate pump base as a stand-alone product.

The patent-pending base, which includes a tray and see-through lid containing NeutraSafe’s proprietary neutralization media sack, is an integral part of the NeutraSafe NSP-50 condensate neutralizing pump. This unit provides condensate neutralization and disposal for condensing appliances with capacities up to 500,000 BTU/h. By selling the base separately, installers can use it in conjunction with any Little Giant VCMA series pump.

The NSP-50 base comes with a neutralization media in a fabric sack, and snaps easily in place on a VCMA series pump. The NSP-50 Base provides a fast, easy way to recharge neutralization media for condensing appliances, with simple visual inspection and industry-leading neutralization.

Taco Comfort Solutions® has expanded their family of easy-to-use, ECM high-efficiency circulators with the addition of the 0034e™ and 0034ePlus™ models. With a maximum of 34 feet of head and 50 gpm, the new circulators offer up to 85% energy savings over a conventional circulator. These circulators are available with cast iron or NSF/ANSI 61 Read more

Taco Comfort Solutions® has expanded their family of easy-to-use, ECM high-efficiency circulators with the addition of the 0034e™ and 0034ePlus™ models. With a maximum of 34 feet of head and 50 gpm, the new circulators offer up to 85% energy savings over a conventional circulator.

Taco Comfort Solutions® has expanded their family of easy-to-use, ECM high-efficiency circulators with the addition of the 0034e™ and 0034ePlus™ models. With a maximum of 34 feet of head and 50 gpm, the new circulators offer up to 85% energy savings over a conventional circulator.

These circulators are available with cast iron or NSF/ANSI 61 & 372 certified stainless steel volutes, so they are ideal for closed-loop heating systems as well as domestic hot water recirculation systems. Both circulators also offer a convenient, rotatable control box cover for a professional look, no matter the orientation of the installed circulator.

The 0034e features an easy-to-use dial with five operating modes, including constant pressure, fixed speed, Taco’s exclusive activeADAPT™ self-adjusting proportional pressure, and 0-10V capability. The 0034ePlus adds proportional pressure and more constant pressure settings as well as a digital display with real-time feedback, including watts, GPM, feet of head, and RPM. Both circulators are dual-voltage 115V/230V.

Both new circulators come with exclusive features that make Taco’s ECM high-efficiency circulators so easy to use, including SureStart® automatic unblocking and air purging, BIO Barrier® black iron oxide protection, dual electrical knockouts, six-inch stranded leads, recessed flange nut-grabbers and double insulation so no ground wire is needed.

For more information, visit www.TacoComfort.com

Caleffi North America, a leader in the manufacture of innovative plumbing and hydronic products, has expanded its commercial digital mixing valve offering with the LEGIOMIX® Station. The Station features a 6000 Series LEGIOMIX electronic mixing valve to provide high performance temperature control for commercial domestic hot water (DHW) systems. A unique self-cleaning function features daily exercising of the Read more

Caleffi North America, a leader in the manufacture of innovative plumbing and hydronic products, has expanded its commercial digital mixing valve offering with the LEGIOMIX® Station. The Station features a 6000 Series LEGIOMIX electronic mixing valve to provide high performance temperature control for commercial domestic hot water (DHW) systems. A unique self-cleaning function features daily exercising of the internal ball valve mechanism to prevent scale build-up and ensure smooth operation.

LEGIOMIX is the only digital mixing valve on the market with automatic scheduling of thermal disinfection to control Legionella bacteria – a globally proven approach to maintaining safe and sanitary DHW. LEGIOMIX also is rated highest in the market for flow capacity. The valve is certified by ICC-ES for compliance with NSF/ANSI 372, ASSE 1017, CSA B125.3 and CSA Z317.1 standards and IPC, IRC, NPC and UPC codes for use in accordance with U.S. and Canadian plumbing codes.

The Stations are pre-built for ease of installation and include a 6000 Series digital mixing valve with union connections, serviceable stainless steel check valves, purge test ports, isolation valves and a LEGIOMIX controller, all pre-mounted on a powder-coated painted steel strut frame. The controller is pre-wired to a 115/24 VAC plug-in transformer. The Stations are available in five sizes from 1” to 2½” copper pipe connections.

“Installing and piping a commercial digital mixing valve properly takes a lot of planning and thought and, unfortunately, mistakes are common. The LEGIOMIX Stations simplify all that because the pipe connections are all pre-labeled and all the components are in the right place. Just hang it on the wall, connect the inlets and outlets and plug in the controller,” said Kevin Freidt, director of product management and technical support.

Taco Comfort Solutions® offers the 4900 Series magnetic dirt separator to provide dual-action dirt separation for closed loop hydronic heating systems. Both hydronic component lifecycle and efficiency are improved with the use of an effective dirt separation system. Taco’s 4900 Series magnetic dirt separator utilizes a powerful, 13,000 gauss magnet in addition to patented PALL Read more

Taco Comfort Solutions® offers the 4900 Series magnetic dirt separator to provide dual-action dirt separation for closed loop hydronic heating systems.

Taco Comfort Solutions® offers the 4900 Series magnetic dirt separator to provide dual-action dirt separation for closed loop hydronic heating systems.

Both hydronic component lifecycle and efficiency are improved with the use of an effective dirt separation system. Taco’s 4900 Series magnetic dirt separator utilizes a powerful, 13,000 gauss magnet in addition to patented PALL ring technology.

The 4900 Series magnetic dirt separator efficiently separates microscopic particles including dirt and magnetite from hydronic fluid with minimal pressure loss. The unit is easily blown down (cleaned) by opening a valve at the bottom of the vessel.

Available sizes range from ¾” to 2” NPT and from ¾” to 1-1/2” sweat. The unit’s maximum operating temperature is 250°F and maximum pressure is 145 PSI.

For more information, visit www.TacoComfort.com.