Demineralizing water will prevent corrosion from occurring in a hydronic system, right? Wrong By demineralizing, we mean removing the ions from the water until it is purified and has zero conductivity. In theory, this sounds ideal for the system however, where there’s oxygen; there’s corrosion! Regardless of how purified the water is, oxidation of the Read more

ShopTalk

Demineralizing water will prevent corrosion from occurring in a hydronic system, right?

Wrong

By demineralizing, we mean removing the ions from the water until it is purified and has zero conductivity. In theory, this sounds ideal for the system however, where there’s oxygen; there’s corrosion!

Regardless of how purified the water is, oxidation of the water will start the process of corrosion. Keeping water purified requires 0.1 PPM or less of oxygen in it, which is A. pretty much impossible, even in a closed loop system, and B. is hard to measure.

How does oxygen enter a closed loop hydronic system?

Oxygen can enter a system, old or new, in multitude of ways. Membranes, rubbers, joints, and faulty AAV’s can suck oxygen into the water. Not forgetting that most boilers now have auto-fill valves, and as soon as new water is introduced to a new system, so is oxygen.

All new components are exposed to oxygen and other contaminants during the manufacturing, transportation, and storage process. Fluxes can build up on the inside of components such as pipework during installation, and air pockets are very common when filling a new system. All of these factors lead to an introduction of oxygen in the system, and that’s when the process of corrosion begins. Remember – corrosion is a natural process that cannot be completely stopped, but it can be prevented in new systems and significantly slowed down in existing systems.

How does oxygen in a system cause corrosion, and what affect can it have on the system?

As oxygen enters a system and mixes with the dissimilar metals and the water, it oxidizes which leads to an increase in iron levels. Oxygen can also bring ions into the water, therefore increasing conductivity, causing further corrosion.

This process can also lead to magnetite build up, which is insoluble iron and is the number one cause of hydronic heating system issues such as faulty thermostats and controls, fouled EMCs, worn pump seals, heat exchanger failures, pipework pin-holes, and system blockages.

So, if purifying the water isn’t the solution, what is?

The ideal solution is to test, clean, protect and maintain the system. This controls pH, the oxygen, and the alkalinity of the water, preventing reactions and corrosion to occur.

Test

The first step to diagnosing the root cause of systems issues or preventing any damage/failures from occurring in new systems is to test the quality of the water. ADEY’s corrosion, pH, and inhibitor will identify whether corrosion has built up, or is building in the system, and provides recommendations on how to restore/treat the system water.

Will a TDS test not identify this?

Testing for TDS (total dissolved solids) tests for everything dissolved in the water which includes iron, copper, chlorides, nitrates, and sulfates. Even cleaner residues, flux residues, and the addition of inhibitor can increase TDS and conductivity, so the answer is no, testing for TDS should not be used to test for corrosion in a system. Testing for TDS should also not be used to identify water hardness. Calcium and magnesium salts cause hardness, but TDS is for all dissolved solids rather than just calcium and magnesium salts specifically, so this is not a true indication of hardness levels in a system. A specific hardness test should be used to test for hard or soft water.

Clean

On any system, it is key to have an air eliminator. An air and dirt separator should be installed on the supply side of the system to aid air removal. On an existing system, first try bleeding any radiators, upgrade failing parts, fix any leaks, and fully cleanse the system a cleaner such as ADEY’s MC3+® cleaner. The cleaner will lift and hold any existing magnetite, scale, and sediment in suspension, ready for it to be flushed out of the system. Similar to cleaning dishes with washing up liquid, adding heat will also aid the clean, so circulating the cleaner around the system while the system is on will increase the effectiveness of the clean.

Protect

For protection, a combination of a magnetic filter such as the MagnaClean® should be installed, and inhibitor such as ADEY’s MC1+® protector should be dosed into the system. Magnetic filters should be installed on the return just before the heat exchanger or boiler to prevent any magnetite from entering this most expensive component. It is also key to choose a filter with a larger magnet directly in the flow of water to aid capture, and of course, one that is easy-to-service.

This 3-step solution is the only way to truly prevent the buildup of magnetite and the costly problems it can cause.

Building information modeling (BIM) helps improve accuracy, efficiencies, job-site safety, productivity, and even profitability potential on commercial projects. With the use of BIM expanding, many contracting firms are now outsourcing work due to resource constraints. However, before partnering with a BIM services provider, it’s important to do your research. Because BIM is a relatively new Read more

Building information modeling (BIM) helps improve accuracy, efficiencies, job-site safety, productivity, and even profitability potential on commercial projects. With the use of BIM expanding, many contracting firms are now outsourcing work due to resource constraints.

However, before partnering with a BIM services provider, it’s important to do your research. Because BIM is a relatively new concept to the construction industry, experience is in short supply. Here are three points to consider along with an informative webinar series to provide guidance when considering a partnership with a BIM services provider.

Location

One of the most important points to consider when choosing a BIM services provider is their location. Some companies are located overseas, which can make live interactions or collaboration challenging. Be sure to choose a provider located in your region, or at least in your

country, so collaboration can happen in real time.

To find out how BIM services providers can benefit your business, watch this Introduction to Uponor BIM Services webinar.

Experience

Ensure the team you’re considering has the necessary knowledge and experience with codes and standards in your jurisdiction as well as specific construction practices in your area. For example, certain commercial projects, such as hospitals, may have certain construction methods that must be adhered to for code. It’s vital the BIM services team you’re partnering with knows these important details.

For information about what BIM services providers can offer, check out this Benefits of Partnering with Uponor BIM Services webinar.

Industry Affiliations

Be sure to partner with a team that has affiliations with industry organizations, such as the American Society of Plumbing Engineers (ASPE), the American Society of Heating, Refrigeration, and Air-Conditioning Engineers (ASHRAE), and the Mechanical Contractors Association of America (MCAA). This will ensure they’re up to date on all the important industry trends and application practices your project may require.

Not all BIM services providers are the same. Discover the Differentiation of Partnering with Uponor BIM Services with this final webinar in the series.

To learn more or to get started on your next project, visit uponor.com/bimservices.

From risers to mains to in-suite piping, PEX is gaining popularity in multifamily construction as contractors are seeing the benefits to their crews’ productivity and their businesses’ bottom line. With sizes up to 3″, PEX is the flexible, durable, cost-effective solution for both domestic water and hydronic heating and cooling systems. It does not pit Read more

From risers to mains to in-suite piping, PEX is gaining popularity in multifamily construction as contractors are seeing the benefits to their crews’ productivity and their businesses’ bottom line.

With sizes up to 3″, PEX is the flexible, durable, cost-effective solution for both domestic water and hydronic heating and cooling systems. It does not pit, scale, or corrode, it offers more stable pricing for greater confidence when bidding a project, and it has no scrap value like copper, so there’s no concern about theft on the job site.

PEX is lighter in weight, which makes it easier for installers to move and adds to job-site safety. It also eliminates the need for heavy-lifting machinery or equipment, which can be costly and cumbersome.

The product is available in long, continuous coils, so installers can complete jobs faster and easier by just bending the pipe instead of stopping to make a connection with each change in direction. And for tight bends, there are bend supports available that simply snap onto the pipe to hold it firmly in place.

The flexible nature of PEX also makes it ideal for renovation, remodel, or re-pipe applications because it’s much easier to squeeze into tight areas and minimizes the need to alter the existing structure.

For connections, there are several options available. However, most professionals use the ASTM F1960 expansion method. This is because it provides a larger-ID fitting that does not restrict flow, and it can never be dry fit, adding peace of mind to installs.

PEX is a great alternative to traditional metallic systems for horizontal main piping. Using a steel support channel along with clamps and fixed points can help reduce linear expansion and contraction and can extend support hangers to be similar to that of metal piping.

PEX is also ideal for running below grade or in a slab. (Always follow local code as some jurisdictions require additional sleeving and protection.) For those types of applications, pre-sleeved PEX is available with color-coded red or blue HDPE sleeving for domestic-water systems.

Learn more about how PEX can benefit your multifamily installs with greater productivity and profitability potential.

When Colorado-based Olson Plumbing & Heating was awarded the plumbing, variable refrigerant flow (VRF) system, and refrigerant lines in the $60 million, 185,000-square-foot Centennial High School project in Pueblo, they needed additional BIM resources to manage their expanding project load. Being committed to BIM as a business model, with only a three-person CAD department and Read more

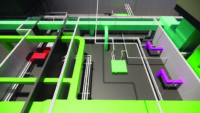

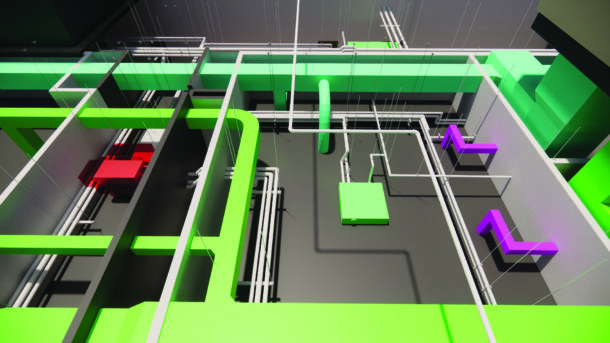

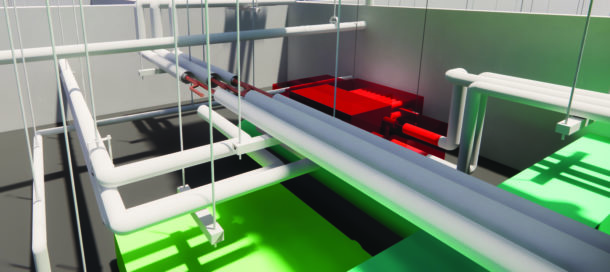

When Colorado-based Olson Plumbing & Heating was awarded the plumbing, variable refrigerant flow (VRF) system, and refrigerant lines in the $60 million, 185,000-square-foot Centennial High School project in Pueblo, they needed additional BIM resources to manage their expanding project load.

Being committed to BIM as a business model, with only a three-person CAD department and this type of skilled labor being extremely hard to find, they found it difficult to develop their in-house capabilities. Having many successful projects with Uponor Construction Services for estimation and design on projects in the past, Olson turned to Uponor BIM Services to help manage the workload on the new high school project.

Using a digital model provided by project architect MOA Architecture, Uponor BIM Services populated it with all the pipe, fittings, equipment, and other products specified. They then moved into the coordination phase to identify potential clashes with other trades on the project.

“With Uponor, we had a professional third party who could take their modeling and drawing to full, fabrication-level detailing,” explains Lana Marsh, project manager, Olson Plumbing & Heating.

Uponor BIM Services provided full plumbing modeling and coordination, full VRF system modeling and coordination, spool and install drawings, and hangers with points for field layout along with representation during multi-trade coordination with the general contractor.

When it came to installation time, this benefitted the Olson team with less rework, reduced job-site waste, and higher workforce productivity. In fact, one project change to raise an underground plumbing drainage line several feet spared Olson from having to dig a deeper trench, which saved significant labor as well as earth-moving equipment rental costs.

“Using Uponor’s resources has enabled us to grow our company without having to create a whole office floor of CAD specialists,” Marsh professes. “We are definitely planning to use them for future projects.”

Learn more about Uponor BIM Services.

Highest Performance Flow Curve in a Compact and Lightweight Design Zurn Industries, LLC announces the release of the new Zurn Wilkins 500XL3 Pressure Reducing Valve. The new Zurn Wilkins 500XL3 Pressure Reducing Valve (PRV) has a patented integral venturi enabling the valve to have best-in-class flow performance. It also has the shortest lay length and Read more

Highest Performance Flow Curve in a Compact and Lightweight Design

Zurn Industries, LLC announces the release of the new Zurn Wilkins 500XL3 Pressure Reducing Valve.

The new Zurn Wilkins 500XL3 Pressure Reducing Valve (PRV) has a patented integral venturi enabling the valve to have best-in-class flow performance. It also has the shortest lay length and is the most compact PRV on the market for increased design versatility and easier drop-in installation.

“The new Zurn Wilkins 500XL3 has industry-leading performance with the flattest flow curve on the market today,” said John Mankins, Zurn Product Manager, Water Safety & Control. “The 3” 500XL3 has a 13 PSI pressure advantage when compared to the leading competitor at the typical 8-foot per second velocity plumbing design limit.”

The new valve’s all-bronze body, stainless-steel stem, and corrosion-resistant cartridge internals withstand heavy wear and harsh environments. The Zurn Wilkins 500XL3 is available in six sizes from 1 inch to 3 inches and with multiple universal connection options, including single union, double union, female thread, and flanged.

The Zurn Wilkins 500XL3 meets lead-free environmental requirements and meets the requirements of NSF/ANSI 61 and is ASSE listed 1003, IAPMO listed, and CSA certified.

Learn more about the new Zurn Wilkins 500XL3 and Zurn’s complete line of pressure reducing valves at Zurn.com.