Led by Vice President Doug Fulton, this new function will seek growth opportunities through corporate acquisitions and joint ventures, as well as internal product development. To further enhance Uponor North America’s ability to deliver innovative plumbing and heating solutions to its customers, the company has announced the creation of a new business function. This new business Read more

PEX

Led by Vice President Doug Fulton, this new function will seek growth opportunities through corporate acquisitions and joint ventures, as well as internal product development.

Vice President Doug Fulton, will lead new business venture development, for Uponor North America.

To further enhance Uponor North America’s ability to deliver innovative plumbing and heating solutions to its customers, the company has announced the creation of a new business function. This new business function will be led by Vice President Doug Fulton and called New Venture Development.

Reporting directly to President Bill Gray, Fulton will lead the exploration, incubation and integration of new products into Uponor’s existing business offerings, while also forging external partnerships. The overarching goal is to expand the company’s growth opportunities in ways that align with Uponor’s business strategy and customer insights.

Fulton’s responsibilities will encompass numerous areas related to corporate growth and expansion: Business Development (M&A/Partnerships), Business Incubation, Construction Services (including Building Information Management), Codes & Standards, Government & Industry Affairs, Project/Stage-Gate Management, and Uponor Innovation LLC.

As part of his business-incubation work, Fulton will oversee the company’s recently announced partnership with Reno, Nevada-based Pestan North America (PNA) to market and sell PNA’s proprietary PP-RCT pipe and fittings. (Note: PP-RCT stands for polypropylene, random copolymer, with modified crystallinity and temperature resistance.) Currently preparing for a formal launch of the product offering, Uponor will serve as PNA’s exclusive distributor throughout the United States and Canada.

“With the creation of our New Venture Development function, Uponor is doubling down on innovation,” says Gray. “We are emphasizing more than ever our commitment to providing innovative plumbing, heating and fire safety solutions to our customers.”

“The name New Venture Development reflects the way we see the business world evolving in the month and years ahead,” Gray continues. “While Uponor will continue to aggressively pursue direct product innovation internally, we envision an equal, if not greater, role for acquisitions, strategic partnerships and joint ventures, as we broaden our scope and capabilities.”

Most recently serving as Vice President of Product Marketing at Uponor, Fulton joined the company in 2017 as senior director of Corporate Strategy and Segment Marketing. He holds an M.B.A. from Indiana University and a bachelor’s degree in Business Administration from the University of Toledo.

Before joining Uponor, Fulton worked as Director of Marketing at Andersen Corporation, a national manufacturer of windows and patio doors. Prior to that, he was Vice President, Business Development – Midwest, for the Walt Disney Company. Fulton spent the first part of his career in various marketing leadership roles in the consumer products industry.

Professionals in the commercial trades who have made the switch from copper or CPVC to PEX for plumbing or mechanical piping will tell you there are four main reasons why: speed, cost, reliability and safety. Because in today’s fast paced commercial building environment, change is rapid and inevitable, budgets and schedules are tight, competition is Read more

Professionals in the commercial trades who have made the switch from copper or CPVC to PEX for plumbing or mechanical piping will tell you there are four main reasons why: speed, cost, reliability and safety. Because in today’s fast paced commercial building environment, change is rapid and inevitable, budgets and schedules are tight, competition is fierce, and skilled labor is shrinking, so keeping valuable employees safe is paramount.

The commercial industry needs a piping solution that can meet all those very important needs, and PEX delivers on every front.

Speed

Because PEX pipe is flexible to bend with each change in direction and the connections are quick to learn and even faster and easier to make, it’s a great solution to meet the skilled-labor shortage challenge and also rapidly accommodate necessary changes in the field.

For example, a PEX piping system in an in-suite multifamily or hospitality project can reduce the number of required fittings by more than half compared to rigid copper or CPVC that require a connection with each change in direction. That can shave days or even weeks off the production schedule, depending on the project size.

Additionally, with today’s aging buildings, PEX is even more beneficial in re pipe applications where existing structures need minimal invasion for renovation (think: historical buildings).

Cost

When it comes to cost, every professional in the commercial world agrees — if the cost is attractive, but the product fails, it’s not worth it. PEX has proven to be both cost-effective and durable, a combination that makes it a win-win for engineers, building owners and installers alike.

Contractors are also finding it’s not just the material costs that are reasonable, it’s also the labor costs that PEX helps manage. Because the flexible pipe requires fewer connections (and those connections are faster and easier to make), it cuts down on labor costs in addition to the bill of material cost for the product.

With materials costing on average up to 30 percent lower than copper, and installs taking up to half the time compared to rigid systems like copper and CPVC, PEX is proving itself to be a smart solution that installers can rely on for consistent pricing, bidding and installations.

Reliability

Every contractor has experienced a leak at one time or another, so a piping material that can help minimize leaks is a huge bonus. Take a look at all the ways PEX helps minimize potential leaks:

- Because the flexible pipe can bend with each change in direction, it reduces the number of fittings and connections and, in turn, the potential for leaks.

- With the PEX cold-expansion fitting system, it is impossible dry fit a connection. The expansion method requires the pipe to first be expanded before inserting a fitting. Then, as the pipe shrinks back down, it creates a strong connection onto the fitting. Eliminating the potential for dry fits means there’s never a concern if the connection is made.

- Flexible PEX is highly resistant to freeze damage because it can expand to accommodate frozen water in the system and then contract back down after the water thaws.

- PEX resists corrosion, pitting and scaling, so there is zero chance of leaks or performance issues due to any of these factors that can plague metallic piping systems.

Safety

With worker safety becoming a bigger issue — especially with the skilled-labor shortage — PEX offers benefits due to its lighter weight. For example, a 300-foot coil of ½-inch PEX weighs about 18 pounds, whereas the same amount of copper pipe weighs around 85 pounds.

Lighter weight means easier maneuvering around the jobsite, less strain on the body and a reduced need for cranes and heavy-lifting equipment.

Also, because all the PEX connection methods (cold expansion, crimp, clamp, compression or push-to-connect) do not need chemicals or open flame, it greatly reduces risk on the job site and also eliminates the need and cost for fire watch requirements.

One last word of advice

Stick with one PEX system brand. Mixing brands for the pipe, fittings, sleeves or rings can greatly reduce (or even void) the warranty. You’ll have more confidence knowing you have the backing of one company if you ever have a service or warranty issue.

If you’re interested in learning more about PEX pipe and fitting systems, visit the Plastics Pipe Institute website at plasticpipe.org or the Plastic Pipe and Fittings Association website at ppfahome.org.

Kim Bliss is the content development manager at Uponor. She can be reached at kim.bliss@uponor.com.

Kim Bliss is the content development manager at Uponor. She can be reached at kim.bliss@uponor.com.

Residential plumbing and HVAC installers take note: you can pipe an entire home with the durability, flexibility and cost-effectiveness of PEX — for plumbing, fire sprinkler systems and radiant floor heating. Here’s how… PEX plumbing With more new homes plumbed with PEX than copper and CPVC combined, you’re probably already aware of the benefits of Read more

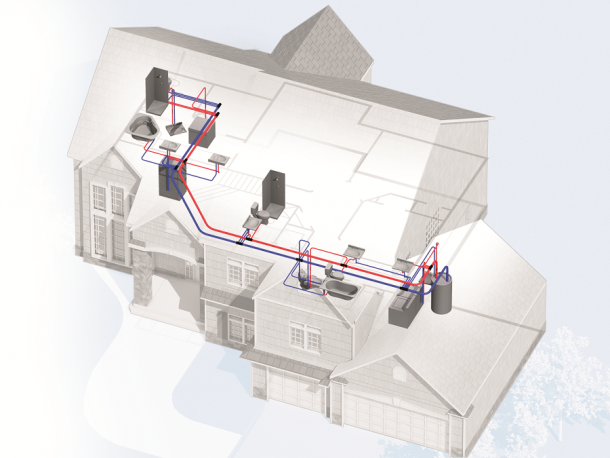

Residential plumbing and HVAC installers take note: you can pipe an entire home with the durability, flexibility and cost-effectiveness of PEX — for plumbing, fire sprinkler systems and radiant floor heating.

Here’s how…

PEX plumbing

With more new homes plumbed with PEX than copper and CPVC combined, you’re probably already aware of the benefits of plumbing with PEX. However, you may not know about a newer, smarter way to install a PEX plumbing system that goes in faster, uses less materials, requires fewer connections and minimizes your liability.

With more new homes plumbed with PEX than copper and CPVC combined, you’re probably already aware of the benefits of plumbing with PEX. However, you may not know about a newer, smarter way to install a PEX plumbing system that goes in faster, uses less materials, requires fewer connections and minimizes your liability.

This innovative design is called Logic plumbing.

The Logic approach uses the flexibility of PEX pipe to minimize connections and reduce potential leak points while also incorporating multiport tees located near fixture groupings to limit the amount of pipe and connections needed.

What’s a multiport tee, you ask? It’s essentially a bunch of tees all molded together to create one long tee with multiple outlets. This design greatly reduces the number of fittings and connections needed to plumb a home (think: reduced materials cost and labor time).

Here’s an example of how a multiport tee saves installation time and materials: a flow-through multiport tee with six outlets has eight connections (six connections for the ports, a main flow-through inlet and a main flow-through outlet). Six regular tees, on the other hand, have a whopping 18 connections. That’s an increase of more than double the connections — and double the installation time.

Here’s an example of how a multiport tee saves installation time and materials: a flow-through multiport tee with six outlets has eight connections (six connections for the ports, a main flow-through inlet and a main flow-through outlet). Six regular tees, on the other hand, have a whopping 18 connections. That’s an increase of more than double the connections — and double the installation time.

Best of all, multiport tees are not considered manifolds, so they can be installed behind walls without the need for an access panel. Double win, there!

For a Logic layout, a main line connects to a multiport tee with distribution lines going out from the multiport to provide water to all fixtures in a single or adjacent grouping. This design uses significantly less pipe than a home-run layout, with just a few more connections. Plus, it requires considerably fewer connections compared to a trunk-and-branch installation.

For example, a 2,300-square-foot, two-story home using a Logic design requires only 637 feet of pipe while a home-run system uses 1,515 feet of pipe. And, while it’s true a Logic installation uses slightly more connections than a home-run layout (59 vs. 48 in the 2,300-square-foot, two-story home example), the amount of pipe savings is significantly more beneficial with the labor and material savings you get with less pipe to install.

A Logic layout also installs much faster compared to a trunk-and-branch system due to the vast reduction in connections. With the two-story home example, a Logic layout uses a mere 16 fittings and 59 connections compared to a whopping 96 fittings and 165 connections for trunk and branch.

PEX multipurpose fire sprinkler systems

If you’re a licensed plumber who wants to add an additional service to your offering, check out PEX multipurpose fire sprinkler systems. These systems combine the fire sprinklers with a home’s cold-water plumbing. It’s genius!

If you’re a licensed plumber who wants to add an additional service to your offering, check out PEX multipurpose fire sprinkler systems. These systems combine the fire sprinklers with a home’s cold-water plumbing. It’s genius!

Installation is remarkably easy — the sprinkler is essentially just another fixture to tie into the plumbing line. For most contractors who already install PEX plumbing systems and have the tools, knowledge and, most importantly, the relationships with the home builders, this is a slam dunk.

Depending on the jurisdiction, multipurpose systems typically don’t need check valves or backflow preventers, and because they combine with the potable plumbing, they don’t use antifreeze, so all those added costs are eliminated.

To get started in most jurisdictions, licensed plumbers just need the appropriate training and a quality design that meets the NFPA 13D standard requirements for home fire sprinkler systems.

If you’re interested in learning more, email me at kim.bliss@uponor.com, and I can get you all the information you need to add this profitable new service to your business.

PEX hydronic radiant floor heating

There’s nothing like the comfort of radiant floor heating — ask anyone who has experienced it. And, homeowners will pay nicely for a quality radiant floor heating system, so there is definitely income potential if you can learn to do it right.

That said, with radiant floor heating, there’s a little more to learn. But, like fire sprinkler systems, starting with a proper design is key. If your design is wrong in the beginning, there’s not much you can do to fix the system once it’s installed.

That said, with radiant floor heating, there’s a little more to learn. But, like fire sprinkler systems, starting with a proper design is key. If your design is wrong in the beginning, there’s not much you can do to fix the system once it’s installed.

Take advantage of the radiant design services many PEX manufacturers offer to guide you through the process. There are several design factors to know, including floor R-values, heat-loss calculations, pipe sizing, loop lengths, pump sizing, manifold types and more.

Once you learn the basics of radiant design and get a few small jobs under your belt, you have the potential to take your expertise to the next level with bigger, more profitable projects. But again, be sure to get the proper design and training before you tackle a radiant project. It will be well worth it in the long run.

To get a jumpstart on all things radiant, visit the following industry websites at radiantprofessionalsalliance.org, healthyheating.com or heatinghelp.com.

Kim Bliss is the content development manager at Uponor. She can be reached at kim.bliss@uponor.com.

Two piping systems that are taking the domestic-water and hydronic heating and cooling landscape to a new level. These innovative solutions are providing the construction industry with systems that are easier to learn (to help with the skilled-labor shortage), faster to install (to meet tight construction schedules) and provide cleaner installation sites (for jobsite safety) Read more

Two piping systems that are taking the domestic-water and hydronic heating and cooling landscape to a new level. These innovative solutions are providing the construction industry with systems that are easier to learn (to help with the skilled-labor shortage), faster to install (to meet tight construction schedules) and provide cleaner installation sites (for jobsite safety).

For PEX pipe, popularity is growing for risers, distribution piping and even direct-burial applications in sizes 3″ and down. Its flexibility, fast installations and stable pricing make it appealing for contractors, and its corrosion resistance and durability in freezing conditions make it highly attractive to building owners.

For PEX pipe, popularity is growing for risers, distribution piping and even direct-burial applications in sizes 3″ and down. Its flexibility, fast installations and stable pricing make it appealing for contractors, and its corrosion resistance and durability in freezing conditions make it highly attractive to building owners.

For copper press, contractors are enjoying a safer, flameless connection system that eliminates solder, heat and flux from the job site while offering contractors a metallic system that is faster and easier to learn and quicker to install.

Now, imagine combining the best of both worlds — PEX expansion and copper press — for quicker, easier training, faster installs and safer jobsites to get the job done right in less time.

With the launch of the industry’s first ProPEX® expansion to copper press transitions, professionals now have a solution for a completely flameless piping system that eliminates the hassles, costs and hazards of soldering while also providing more efficient installs.

With the launch of the industry’s first ProPEX® expansion to copper press transitions, professionals now have a solution for a completely flameless piping system that eliminates the hassles, costs and hazards of soldering while also providing more efficient installs.

Watch how easy it is to make these transitions.

Manufactured from high-quality, lead-free brass to meet all local and national domestic-water building codes, the transitions are available in both male and female configurations with the female adapters featuring an EPDM rubber O-ring for a dependable seal.

Best of all, they feature a patented design for securely fastening the pipe and fitting together, eliminating the need for a stainless-steel ring commonly used in large-dimension copper press fittings.

Compared to soldering copper, these transitions reduce an overall project timeline by an average of 71%, helping to manage a project’s schedule and, ultimately, the bottom line. And because they are backed by a 25-year transferable limited warranty, the transitions offer additional confidence and peace of mind.

So if you’re like most construction professionals out there, feeling the crunch of the labor shortage but still want the quality of a professional piping system, look to a hybrid PEX expansion and copper press system. The end result can be money in the bank.

To learn more about the transitions, visit uponorpro.com/copperpress_us.

Kim Bliss is the content development manager at Uponor. She can be reached at kim.bliss@uponor.com.

With winter comes the inevitable rise in the number of burst pipes all plumbers will be tasked with repairing. Fortunately, John Guest has plumbers covered with John Guest’s high-tech ProLock slip connectors, which provide plumbers with a quick, simple, and easy fix for burst pipes. John Guest slip connectors come in two sizes and can Read more

With winter comes the inevitable rise in the number of burst pipes all plumbers will be tasked with repairing. Fortunately, John Guest has plumbers covered with John Guest’s high-tech ProLock slip connectors, which provide plumbers with a quick, simple, and easy fix for burst pipes. John Guest slip connectors come in two sizes and can be used to fix pipe bursts on PEX, CPVC, and copper pipes, providing an efficient solution to a litany of burst-pipe problems that any plumber is bound to face this season.

With winter comes the inevitable rise in the number of burst pipes all plumbers will be tasked with repairing. Fortunately, John Guest has plumbers covered with John Guest’s high-tech ProLock slip connectors, which provide plumbers with a quick, simple, and easy fix for burst pipes. John Guest slip connectors come in two sizes and can be used to fix pipe bursts on PEX, CPVC, and copper pipes, providing an efficient solution to a litany of burst-pipe problems that any plumber is bound to face this season.

John Guest slip connectors feature push-fit connections, making rapid installations easy and allowing plumbers to increase the number of visits they can make each day. In addition to being easy to install, John Guest pipe fittings can also solve one of the major issues with burst pipes: leakage. The push-fit fitting allows all of this to be quickly accomplished without any additional pipe work being performed by the plumber.

John Guest slip connectors are also built with versatile use in mind, and they work equally well with both hot and cold pipes, again providing coverage across the entire spectrum of possible burst-pipe issues that one of John Guest’s customers may encounter. John Guest slip connectors are made with lead-free, non-toxic, and non-flammable materials so plumbers can feel secure after installing these connectors and then allowing them to run without constant monitoring. Like all John Guest products, ProLock slip connectors are made with an advanced polymer material, assuring our customers that they are receiving only the highest-quality performance. No matter how many precautions people take to prevent winter pipe bursts, some bursts are unavoidable. For this season, John Guest slip connectors are a must-have for any plumber.

John Guest slip connectors are also built with versatile use in mind, and they work equally well with both hot and cold pipes, again providing coverage across the entire spectrum of possible burst-pipe issues that one of John Guest’s customers may encounter. John Guest slip connectors are made with lead-free, non-toxic, and non-flammable materials so plumbers can feel secure after installing these connectors and then allowing them to run without constant monitoring. Like all John Guest products, ProLock slip connectors are made with an advanced polymer material, assuring our customers that they are receiving only the highest-quality performance. No matter how many precautions people take to prevent winter pipe bursts, some bursts are unavoidable. For this season, John Guest slip connectors are a must-have for any plumber.