Aalberts integrated piping systems (IPS), a global leader in advanced integrated piping systems for the distribution and control of liquids and gasses, is excited to announce its participation in the upcoming ASPE Convention & Expo, taking place from October 18-23, 2024 in Columbus, OH. Aalberts IPS will be exhibiting at booth #1815, where attendees can Read more

PVF

Aalberts integrated piping systems (IPS), a global leader in advanced integrated piping systems for the distribution and control of liquids and gasses, is excited to announce its participation in the upcoming ASPE Convention & Expo, taking place from October 18-23, 2024 in Columbus, OH. Aalberts IPS will be exhibiting at booth #1815, where attendees can explore the company’s latest innovations, services, and product lines, designed to deliver complete, tailored piping solutions across industries.

Aalberts IPS is renowned for its mission-critical products surrounding valve and connection technology, with a legacy spanning 96 years under its “Apollo”® Valves brand. The company offers a wide range of products, including: ball valves, butterfly valves, safety relief valves, control valves, mixing valves, backflow preventers, and more. These products are engineered domestically to meet the needs of key verticals from commercial to industrial and utility markets globally.

Aalberts IPS is renowned for its mission-critical products surrounding valve and connection technology, with a legacy spanning 96 years under its “Apollo”® Valves brand. The company offers a wide range of products, including: ball valves, butterfly valves, safety relief valves, control valves, mixing valves, backflow preventers, and more. These products are engineered domestically to meet the needs of key verticals from commercial to industrial and utility markets globally.

At the ASPE Convention & Expo, Aalberts IPS’ booth will feature key information about the company’s design and field services, as well as products like the Revit plug-in among the Shurjoint and “Apollo”® product lines. Aalberts IPS provides expert advice and support for piping applications, from the initial planning stages to the final implementation of piping systems. Their unique design service ensures that every project is optimized for efficiency and effectiveness. Additionally, Aalberts IPS offers a comprehensive range of field services to ensure that piping systems are installed correctly and operate efficiently. Their experienced team provides on-site support, from installation to maintenance, ensuring long-term system reliability with minimal downtime.

Booth visitors will be able to witness the Aalberts IPS Revit plug-in, a powerful tool designed to streamline the design process, allowing engineers and architects to easily integrate Aalberts IPS products into their projects. This plug-in enhances project accuracy and efficiency, ensuring things are done right the first time and minimizing costly extended lead times. The Shurjoint range of mechanical piping solutions, which will also be highlighted at the event, is known for its versatility and ease of installation. This product line is designed to offer reliable and extremely durable pipe connections for a variety of piping systems whereas the “Apollo” SmartPress® line of press fittings and valves offer quick and secure connections, reducing installation time and costs while ensuring long-term reliability.

Finding the perfect mix of glycol and water in a hydronic system doesn’t have to be hard. Guest presenter John Panasewicz will discuss the best ways to specify and maintain water-glycol blends in boilers, chillers and other heat transfer applications. This pre-heating-season webinar will clear up the confusing aspects of antifreeze for designers and installers Read more

Finding the perfect mix of glycol and water in a hydronic system doesn’t have to be hard. Guest presenter John Panasewicz will discuss the best ways to specify and maintain water-glycol blends in boilers, chillers and other heat transfer applications. This pre-heating-season webinar will clear up the confusing aspects of antifreeze for designers and installers.

→ How do you know what percentage of glycol is best for your project?

→ What is the best way to maintain system fluid?

→ What is the difference between freeze and burst?

→ How can recovered glycol be reused?

→ How do air and dirt separation affect system fluids?

John was a founding member of the ASTM D15.30 Subcommittee on Heat Transfer Fluids and will provide both technical and practical insights on this topic. He is the Director of Technology at G2 Solutions in Denver, Colorado.

Allen Stanley has been promoted to vice president, fittings manufacturing and distribution, and Rudy Smith to vice president, valve manufacturing. Elkhart, Ind. — NIBCO INC. has announced the promotion of Allen Stanley to vice president, fittings manufacturing and distribution, and Rudy Smith to vice president, valve manufacturing. Both Stanley and Smith will report to Ashley Read more

Allen Stanley has been promoted to vice president, fittings manufacturing and distribution, and Rudy Smith to vice president, valve manufacturing.

Elkhart, Ind. — NIBCO INC. has announced the promotion of Allen Stanley to vice president, fittings manufacturing and distribution, and Rudy Smith to vice president, valve manufacturing.

Both Stanley and Smith will report to Ashley Martin, president and COO, NIBCO.

Allen Stanley

“Allen and Rudy have long careers with NIBCO and the knowledge and expertise that they both bring to these roles will be valuable for the success of our organization,” said Martin. “Join me in congratulating them on their well-deserved promotions.”

In this new role, Stanley has responsibility for the Stuarts Draft, Virginia manufacturing operations and the Demand Planning department, along with his current responsibilities for the U.S. distribution centers, world headquarters logistics, and all plastic manufacturing facilities.

Stanley began his career in 1997 at NIBCO as administrative manager at the Atlanta Distribution Center. He held a variety of roles of increasing responsibility including operations manager at the Elkhart Distribution Center, manager, distribution and transportation, and most recently, director, plastic fittings manufacturing and distribution.

Stanley holds a bachelor’s degree in marketing from the University of West Georgia in Carrollton, Georgia. He also earned his master’s degree in marketing from Georgia State University in Atlanta, Georgia.

Rudy Smith

In his new role, Smith will have responsibility for NIBCO’s Blytheville, Arkansas, facility, along with the company’s Nacogdoches, Texas, McAllen, Texas, and Reynosa, Mexico facilities.

Smith began his career at NIBCO in 1996 in logistics at NIBCO’s world headquarters. Two years later, he was promoted and transferred as operations manager of NIBCO’s Nacogdoches facility. He held various roles from production superintendent, plant superintendent, plant manager, and most recently, senior plant manager at Reynosa, prior to his new role.

Rudy holds a bachelor’s degree in management from Rice University, in Houston, Texas.

By joining forces with Uponor, GF is set to become a global leader in sustainable water and flow solutions. To support this ambition, complementary businesses will be grouped together under one roof: the new division GF Uponor will focus on Building Technology, whereas the infrastructure and utility business will move to GF Piping Systems. Michael Read more

By joining forces with Uponor, GF is set to become a global leader in sustainable water and flow solutions. To support this ambition, complementary businesses will be grouped together under one roof: the new division GF Uponor will focus on Building Technology, whereas the infrastructure and utility business will move to GF Piping Systems. Michael Rauterkus will join GF’s Executive Committee and will lead the new division together with his Uponor leadership team.

After all conditions of the tender offer have been fulfilled, GF closes the transaction as of 13 November 2023.

To accelerate the implementation of GF Piping Systems’ Strategy 2025 and to further benefit from global megatrends, GF will start an ambitious value creation program to unleash the full potential of this acquisition. GF Piping Systems will focus on the industrial and utility business, providing its customers with sustainable leak-free piping solutions for numerous end markets such as microelectronics, water treatment, energy, chemical processing, marine, data centers or water & gas utilities. Uponor’s infrastructure business will become part of GF Piping Systems and will further strengthen the division’s portfolio to provide customers with combined solutions.

In the new division, GF Uponor, the building technology businesses will be combined to offer a complementary portfolio for safe and clean water, as well as energy efficient heating and cooling. The consolidation of complementary businesses provides an ideal platform to develop markets with high potential for both divisions. As the brand Uponor stands for high quality and innovation, it will drive growth in intelligent Building Flow Solutions.

These organizational changes will be implemented during the course of 2024 while GF will ensure operational excellence and business continuity to customers.

“We will continue to implement our strategy, and leverage powerful global trends, such as the need for safe and clean water, or more efficient energy use,” GF CEO Andreas Müller said. “On behalf of all my colleagues, I am happy to welcome Uponor employees and start this new chapter together.”

The 180,000-sq.-ft. plant in Shalersville, Ohio, will break ground in November 2023 and is expected to be operational in early 2025. Broomfield, Colo. — Viega recently announced that it will build a new manufacturing facility for its ProPress® and MegaPress® products in Shalersville, Ohio, about 40 miles southeast of Cleveland. Viega LLC President and CEO Read more

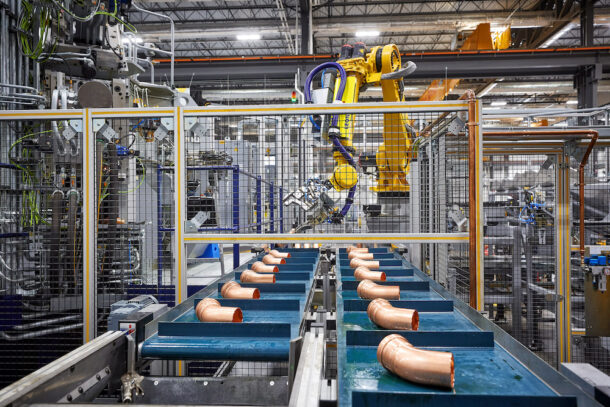

The 180,000-sq.-ft. plant in Shalersville, Ohio, will break ground in November 2023 and is expected to be operational in early 2025.

Broomfield, Colo. — Viega recently announced that it will build a new manufacturing facility for its ProPress® and MegaPress® products in Shalersville, Ohio, about 40 miles southeast of Cleveland. Viega LLC President and CEO Markus Brettschneider made the announcement.

“This is an exciting time at Viega, as our growth continues to prompt the expansion of our North American footprint,” said Markus Brettschneider, CEO and President of Viega LLC. “This new facility in Ohio, along with recent investments in our existing Kansas facility, further supports our growing demand and is part of Viega’s plan to increase North American production. We look forward to expanding our presence in this part of the country to further support our customers.”

The 80-acre parcel in Shalersville and the construction of the new plant represent an investment of approximately $200 million in Ohio. Viega’s business continues to grow in the U.S., and the additional plant will help support the increased demand for Viega products. It also aligns with the company’s sustainability goals, which include reducing the carbon emissions associated with importing products by manufacturing more items in the U.S. The new facility will be completely carbon neutral from the start, supporting the company’s long-term goal of achieving net-zero carbon emissions for all their plants by 2035.

“The expansion of our operations into Ohio shows our commitment to creating highly skilled jobs in the U.S.,” said Marki Huston, Head of Manufacturing for Viega LLC. “Our goal is to build more sustainable manufacturing processes and continue developing tomorrow’s workforce. With production scheduled to begin in early 2025, we expect to start hiring for positions as soon as January 2024, bringing more than 68 new jobs to the area over the next few years.”

Viega recently announced investments in new equipment for its McPherson, Kansas, manufacturing and distribution facility. In addition, Viega supports its customers and partners through distribution centers in Reno, Nev. and Carlisle, Penn., with more North American expansion planned for 2024 and 2025.

Viega worked with local, regional, and state organizations, including Team NEO, JobsOhio, Portage Development Board and the Shalersville-Streetsboro Joint Economic Development District on tax credit assistance and to select the 80-acre site. “We have a great manufacturing legacy, dedicated talent pool, and future-oriented industry resources to support Viega’s new operations,” said Team NEO Chief Executive Bill Koehler. “Along with JobsOhio and our local partners, we welcome Viega to the Northeast Ohio Region. We are confident they will thrive here.”