Webstone’s new G-Series products enable users the flexibility to create a variety of connection combinations for hydronic, plumbing, hydronic, radiant, solar and geothermal applications. These lead-free, dezincification-resistant brass valves and fittings feature G-threads and G-unions, making it easy to mix and match end connections to create the perfect products for any job. More than 250 Read more

Radiant

Webstone’s new G-Series products enable users the flexibility to create a variety of connection combinations for hydronic, plumbing, hydronic, radiant, solar and geothermal applications.

These lead-free, dezincification-resistant brass valves and fittings feature G-threads and G-unions, making it easy to mix and match end connections to create the perfect products for any job. More than 250 different combinations can be created from a single G-Series valve body for a completely custom installation.

End connection fittings are available in FIP, MIP, SWT, Press, Push, F1960 PEX, or F1807 PEX, in piping sizes 1/2″ – 2″. New G-Series products include two ball valves, two Pro-Pal® Ball Drains™, two pressure gauge fittings, an isolation valve, a union fitting, and an end cap. Press transition bodies are also available on select products to save even more time, with quick, clean, and consistent results.

For more information on NIBCO’s Webstone G-Series product line, visit: www.nibco.com/brands/webstone/g-series/.

Providence, R.I. – The first annual John Hazen White III Memorial Tribute was held under sunny skies on Saturday, April 27, at Narragansett Brewery. It was a memorable day filled with unity and celebration. Participants included Taco employees, cherished family members, dear friends, and valued partners at Community Preparatory School. The event began with a Read more

Providence, R.I. – The first annual John Hazen White III Memorial Tribute was held under sunny skies on Saturday, April 27, at Narragansett Brewery. It was a memorable day filled with unity and celebration. Participants included Taco employees, cherished family members, dear friends, and valued partners at Community Preparatory School.

The event began with a meaningful one-mile walk/run, symbolizing the shared commitment to our community and its well-being. The slogan, “Come Walk or Run in Memory of Maddie’s Daddy,” provided an extra special, heartfelt incentive.

Following the walk/run, the festivities continued at the brewery, where attendees enjoyed live music, delicious food, and the joyous camaraderie of being together. It was a time to reflect on the impact of John Hazen White III’s legacy and to honor his vision of making a positive difference in the lives of others.

“Seeing everyone here today means so much to us,” said Kate White, Corporate Social Responsibility Partner at Taco. “This is exactly the type of event that John would have loved—an opportunity to spend time together with family and friends for such a wonderful cause. We wish he was still here, but we know he lives on in all of us,” Kate mused.

“Seeing everyone here today means so much to us,” said Kate White, Corporate Social Responsibility Partner at Taco. “This is exactly the type of event that John would have loved—an opportunity to spend time together with family and friends for such a wonderful cause. We wish he was still here, but we know he lives on in all of us,” Kate mused.

John H. White, Jr, Executive Chairman and Owner of Taco, reflected on the day. “Today’s event was truly special. Sharing time together with friends, family and the Taco community is the perfect way to celebrate John’s life and the joy he brought to all those who knew him,” said John.

“We are so thankful for everyone joining us here to pay tribute to John,” said Ben White, Program Manager, Business Operations at Taco. “He made us all better people and continues to have a positive impact on our lives. As we have been saying, love is not a big enough word when it comes to John,” concluded Ben.

“We are so thankful for everyone joining us here to pay tribute to John,” said Ben White, Program Manager, Business Operations at Taco. “He made us all better people and continues to have a positive impact on our lives. As we have been saying, love is not a big enough word when it comes to John,” concluded Ben.

We invite you to consider donating to the John Hazen White III Endowed Scholarship fund at Community Preparatory School. Your generous donations will help us continue his legacy of empowering young minds and transforming lives. Details on how to donate can be found at https://bit.ly/44inhTJ.

By Kolyn “Coach” Marshall No matter where we go these days it seems as if there’s always someone trying to upsell us on something. Truth is, the art of upsell is nothing new. Walk into a fast food restaurant and you’re asked if you want to super-size it. Go to the theater and you’re asked Read more

By Kolyn “Coach” Marshall

No matter where we go these days it seems as if there’s always someone trying to upsell us on something.

Truth is, the art of upsell is nothing new. Walk into a fast food restaurant and you’re asked if you want to super-size it. Go to the theater and you’re asked if you want to make your popcorn a combo deal. Heck, even Amazon’s in on the program.

Ubiquitous upsells can be awfully annoying, especially when it’s something you know a lot about. But, what if it’s something you know nothing about? Or, better yet, didn’t know to even ask?

This last question is where I find a lot of potential radiant buyers. They simply don’t know enough about what’s out there to ask.

This is where you—Neighborhood Radiant Installer—come into play.

It’s your opportunity to throw out the option of radiant floor heating or snowmelting. Sounds easy, right? Well . . . sort of. In order for you to be able to effectively talk about radiant, it can be helpful to know what there is to talk about.

Understanding the want

Depending on the audience, say, home or a business owner, the want or need may vary. For homeowners, they may want to be more comfortable. There’s a factor of efficiency or cost savings, but those are typically secondary to comfort. People really don’t like being cold.

Comfort, however, takes on many forms. But, as the Neighborhood Radiant Installer, it’s important to know what comfort means. One aspect is keeping the room temperature between 68 and 70 degrees. The other facet is knowing how occupants interact with the interior space. The key driver for comfort is floor temperature.

Ever step out of the shower onto a cold tile floor? In that instant it’s pretty easy to connect to what cold is. Oddly enough, our feet dictate our comfort more than air temperature. It’s the main reason why we have slippers and wool socks. If our feet are warm we feel warmer.

So the easiest way to feeling comfortable is to keep the floors from being cold. Radiant heat does that with most radiant systems maintaining a floor temperature between 75 and 85 degrees.

Business owners tend to have a slightly different goal in mind. Their focus is more on customer safety, especially when the weather turns cold and the freezing rain and snow start to fall. Or: employee satisfaction, a great incentive in retaining, and attracting, employees.

As for safety, injuries due to slips and falls plague business owners constantly. It’s a seasonal risk, and source of concern.

Radiant snowmelting systems help keep walkways, parking lots, and access ramps ice and snow free all winter long. This means no more early morning labor; shoveling snow is a thing of the past. No more chemical ice melt. This alone eliminates another key concern: icemelt tends to get picked up by customer’s shoes and tracked inside, eventually taking its toll on the floor.

The upgrade package

So a spark is struck. Warm floors are something that wasn’t expected but is now very much wanted.

How are these once cold floors now warmed? There are two main ways to provide radiant floor heat: hydronically with water, or through electric resistance.

Hydronic systems rely on tubing being installed in the floor and connected to a heat source. Tubing options range from PEX, to PE-RT, to EPDM rubber. Tubing is connected to a series of manifolds, then those manifolds connect to a boiler, or other equivalent heat source.

If the area to be heated is small, say only a kitchen or bathroom, then an electric product may be best; these use electrical resistant wire or cable to generate heat. Wire is embedded in a lightweight concrete or thinset generally under tile or other masonry material. One of the advantages of electric is there is no need for a mechanical room and no need to physically run piping back through a home or facility. Electrical installations tend to be less invasive but also tend to be reserved for smaller areas.

With both electric and hydronic systems there are options for controls and thermostats. Most of today’s systems incorporate some form of connectivity feature, giving remote access to users.

Delivering the Goods

Congratulations Neighborhood Radiant Installer! The Enlightened Customer has decided to go with the radiant upgrade. Now what?

Now it’s time to figure out how to get all those tubes and wires where they’re supposed to go.

Hydronic tubing is generally installed in one of two ways, either in a concrete slab or under a frame floor. In a concrete slab, tubing is typically 6, 9, or 12 inches on center with the tubing approximately 2 inches down from the top. In a frame floor, the tubing is secured to the subfloor, often with heat transfer plates. These plates secure the tubing (usually PEX or PE-RT) to the subfloor while providing good conductive heat transfer to the floor.

Electric systems are installed in a similar fashion to hydronic slabs with the difference being the wire is generally installed on top of the floor in ½ inch thinset with tile or other stone material as the finished floor covering. An electric system is then connected a controller or thermostat.

Both hydronic and electric systems then operate in the same way any forced air system does. The controller or thermostat is set to the desired temperature and the system operates automatically.

Satisfied Customers

So how does our Neighborhood Radiant Installer know the system is working as expected and the customer is happy? It’s simple: our Honorable Customer won’t be able to stop talking about the most comfortable heat they’ve ever experienced.

Becoming the go-to radiant expert is the best way to keep the future looking warm and bright.

Kolyn “Coach” Marshall, based in Springfield, Mo., is Systems Engineering Manager at Watts Radiant.

I’ve always had this romanticized view of Alaska. Ahh, The Last Frontier. It’s been on my bucket list for years, and it was actually one of the places my father and I had initially planned to visit before he passed away. There is something mystical about it — the beauty of the mountains, the wildlife, and Read more

I’ve always had this romanticized view of Alaska. Ahh, The Last Frontier. It’s been on my bucket list for years, and it was actually one of the places my father and I had initially planned to visit before he passed away. There is something mystical about it — the beauty of the mountains, the wildlife, and I would think you would have to have something special to live and work there. “Living in Alaska is an adventure. It is an extreme place to live with beautiful amazing summers with almost 24 hours of daylight to extreme cold, dark, snowy winters. There is no shortage of extreme activities to choose from,” says Everett Knudsen, owner/operator, 907 Heating & Plumbing, Anchorage.

Working in Alaska is extreme as well, says Knudsen, especially for the heating and plumbing trade. “Extreme cold (-20 F) is not uncommon in Anchorage January through February, and even colder in more northern locations of Alaska (-50 to-70 F). I’ve had a project that required taking a helicopter to get to the job site and another that required taking a boat,” says Knudsen.

“I used my own boat to travel back and forth to the jobsite over the course of about a week and a half. When we launched the boat there was about 6” of snow on the boat launch and had to chain up the box van just to get the boat in the harbor. Then the harbor was frozen over and one person had to sit on the bow with a piece of steel pipe and break up the ice in front of the boat to get the boat out of the harbor. The boat ride to the jobsite was out of Valdez harbor through the Bay to the Narrows. The mountains come right into the water, and just an amazing 30-minute commute.

“I used my own boat to travel back and forth to the jobsite over the course of about a week and a half. When we launched the boat there was about 6” of snow on the boat launch and had to chain up the box van just to get the boat in the harbor. Then the harbor was frozen over and one person had to sit on the bow with a piece of steel pipe and break up the ice in front of the boat to get the boat out of the harbor. The boat ride to the jobsite was out of Valdez harbor through the Bay to the Narrows. The mountains come right into the water, and just an amazing 30-minute commute.

“On our final trip back at the end of the project was very dangerous, the weather had turned very bad with high winds and blowing snow. We didn’t want to be stuck on the remote jobsite any longer so we went for it. The waves were 8-12’ and it was blizzard conditions. For my 22’ jet boat we were in way over our heads. Any type of engine failure would surely cost the two of us our lives. We could barely see the glimmer of the harbor lights as we slowly pushed through the storm. The windshield of the boat was freezing over and we could barely see. The boat was crashing over each wave and the spray was freezing and build up on the boat. I was terrified, as was my helper. Luckily, we made it back safe, very shaken, but safe. It was an experience I will never forget. You have to respect the extreme of Alaska or it could get the better of you.”

Plumbing in -20 F degree weather is very difficult and can be dangerous, reiterates Knudsen. “I’ve had my Channellock pliers freeze/stick to my gloves. I’ve entered houses full of ice from frozen split pipes. Working outside requires wearing the appropriate gear, and sometimes I’m only able to work outside for 30 minutes at a time before getting too cold. “Sometimes I have to use a pipe thaw machine (buzz box) or large welder to thaw frozen pipes to restore domestic water or heat. And usually this means wet gloves and hands, which does not match well with freezing temperatures,” says Knudsen.

Needless to say, frozen cordless tools—mainly batteries—have to be kept inside once it gets colder than 20 or so and calls at all hours of the night, and working long late hours because time is of the essence to avoid more damage to property when it is very cold out, is imperative.

But what about the occasional wildlife encounter? Typically, while working in Anchorage it is safe, says Knudsen. There is frequent moose and the occasional bear, and depending on the part of Anchorage, there can be some added risks in the suburbs, he adds. “Springtime is always a good time to be cautious. The moose are having their babies and mama moose are very protective of their babies. Also, bears are coming out of hibernation and looking to eat anything. Yet, in my 25 years in Anchorage, I have not had a problem with either moose or bear.”

There are usually 1-3 or more bear attacks each summer in and around Anchorage. It is important to be aware of your surroundings in the summertime. “In the summer, when I go hiking anywhere in Alaska, I carry a 10mm or 44mag pistol for bear protection. Surprising a bear in the wild is where the problems lie and you never know when that will happen and it’s better to have it and not need it, then need it and not have it,” says Knudsen.

Into the Wild, and into the Trades

Originally from the Northwest, Knudsen, moved from Olympia, Wash., to Alaska in 1994. Knudsen answered a help wanted ad in the Anchorage local newspaper back in 1998 for “Local Plumbing Company Seeking Shop Helper.” He was 19 years old. “I started at Anchorage Plumbing & Heating, and at that time it was not my intention to be a plumber or have a plumbing career, I just needed a job, and I didn’t mind labor-type work.

Bottom line, Knudsen started a family at a very young age and needed to provide for them. “My son was six months old when I started plumbing at age 19; eight years later my daughter arrived. Family was my main drive to become successful and work the hardest I could. I wanted to provide the best environment for them that I possibly could, while setting an example of honesty, hard work and determination as an ethical backbone for success,” says Knudsen.

Bottom line, Knudsen started a family at a very young age and needed to provide for them. “My son was six months old when I started plumbing at age 19; eight years later my daughter arrived. Family was my main drive to become successful and work the hardest I could. I wanted to provide the best environment for them that I possibly could, while setting an example of honesty, hard work and determination as an ethical backbone for success,” says Knudsen.

At that time, Knudsen didn’t have a clue about how plumbing or heating worked, or how vast and essential it really was. “Turns out that I was gifted with a solid mechanical inclination and I caught on very quickly. Within two months, AP&H put me in my own van and started having me do basic plumbing and heating service calls. From there I worked for two other companies over the course of eight years. At year five—shortly after getting my journeyman’s license—I learned I could get my own plumbing contractor licenses so I set my sights on completing that goal. This goal was big for me since I didn’t have any type of formal education. I acquired my Mechanical Administrators License in the Unlimited Plumbing category for the state of Alaska. Then I acquired my Anchorage City Contractor’s License and started working for myself.”

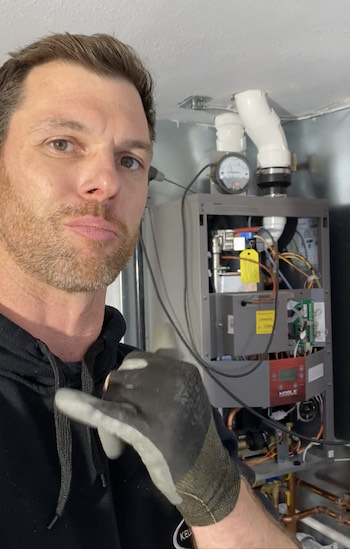

Knudsen has been self-employed for the past 13 years as a one-man shop, with occasional hired experienced help along the way when needed. He has done all types of work throughout his career; he started with residential service and repair work, which includes retrofit of boilers, forced air furnaces, fireplaces, water heaters, as well as regular maintenance, remodels, repairs of heating and plumbing systems.

A catalog of his work includes: Residential gas boilers including baseboard heat, radiant heat, flat plate exchangers for snow melt and pool heating, multi temp injection systems, commercial snow melt 10,000 sq. ft., 3 x 500k Knight boilers; oil boilers residential and commercial; brazed 3” copper and worked with 2” REAHU PEX; installed/replaced forced air furnaces of all types from closets to crawl spaces; HRV installation to maintain good air quality in our cold climate; retrofit/upgrade hot water system in 30 unit apartment building cut fuel and water usage by 50%; new construction on several custom homes, triplexes, duplexes, and single family homes; low voltage controls of all types. I do enjoy wiring controls; water heaters of all types and sizes; HDPE butt fusion and saddle fusion for new water supply to subdivision; multiple large generators, fuel lines, exhaust piping, fresh air supply—24” VFD fans—and ducting to exhaust radiator heat out of building; 25-unit trooper housing complex in Bethel, Alaska; and HRV for FAA Housing in Nome, Alaska.

And occasionally, he does some new construction projects here and there. “Service work is very rewarding for me. To help a homeowner resolve their heating and plumbing challenges and provide excellent customer service never gets old to me. The vast majority of customers are very happy to receive excellent service and are happy to pay for the service provided. It’s a win-win situation, I enjoy this type of situation, as does the customer.”

And occasionally, he does some new construction projects here and there. “Service work is very rewarding for me. To help a homeowner resolve their heating and plumbing challenges and provide excellent customer service never gets old to me. The vast majority of customers are very happy to receive excellent service and are happy to pay for the service provided. It’s a win-win situation, I enjoy this type of situation, as does the customer.”

And that’s one the biggest ethical factors that Knudsen has based a lot of his business principals on: Treat every project as if it were his. “I put myself in the client’s shoes, asking myself the question, ‘how would I want this to go if I was the client’ or the golden rule, ‘treat others as you wish to be treated.’ I was raised with a couple of core principals—hard work and respect. Applying these principles and ethics in my plumbing career has grown into something that has provided me with numerous lessons for personal growth, and a good income as well.”

What does Knudsen love most about his job? “I love building something with my hands and mind, then having a client look at the work and saying, ‘Wow, that looks amazing; how come the other plumber didn’t do that?’”

Again, Knudsen loves the win-win aspect of the job. “I love a customer that is super appreciative and complimentary, and at the same time, I’m making a living. This career constantly gives me opportunity for professional and personal growth. It enables me to learn new plumbing techniques, learn new customer relation skills on each job, and the scene always changes with new challenges every day. I love the variety.”

But what are the issues Knudsen sees in the trades that need addressing? Honesty, Integrity and Craftsmanship, says Knudsen. “These are the things that I saw missing as I was coming up in the trade, and I still see quite a bit of it missing today, especially in residential work. Too many plumbing businesses/contractors influence customers into work or products they do not need. Then do marginal quick installs to maximize profits and move to the next.

But what are the issues Knudsen sees in the trades that need addressing? Honesty, Integrity and Craftsmanship, says Knudsen. “These are the things that I saw missing as I was coming up in the trade, and I still see quite a bit of it missing today, especially in residential work. Too many plumbing businesses/contractors influence customers into work or products they do not need. Then do marginal quick installs to maximize profits and move to the next.

A lot of Knudsen’s learning has been on-the-job training. To him, that means the client has paid for his education as a tradesman. He does his best to honor the valuable experiences he has gained while working for clients. If there is a situation where Knudsen made a mistake due to lack of experience or making an assumption and was incorrect, he makes sure not to charge the customer for that time for two reasons: 1) They are paying for an experienced professional to resolve their problem correctly and efficiently. 2) The value of the experience will vastly outweigh the few extra dollars he would have made on that one job, by giving me the experience for the jobs to come in the future. “Doing the right thing when no one else will know is HUGE!! That is true integrity!”

Knudsen advises to do your best to take pride in your work whenever and wherever you can. “Unfortunately for plumbers and mechanical workers, our work is buried in the ground—a wall, a crawlspace, a mechanical room—where not much of its glory and existence is on display. Even so, still take the time to have a clean, proper, well-installed system, even if it is to be covered up, it is still about integrity and pride in craftsmanship,” says Knudsen.

The trades are a wonderful opportunity for young people not really sure what they want to do with themselves, says Knudsen. Regardless, adds Knudsen, young people will need to work, and getting into a trade is super valuable, not to mention they will get paid to learn. “I do not think there is another situation that can compare to the benefit of getting paid to learn a trade. A trade is not any less important than a doctor, lawyer or any of the other careers that require a college degree. For several years, in the early stages of my career, I felt less than because of my lack of schooling. Now, that lawyer whose heat is not working calls me to come fix it. Trade workers are just as smart and valuable as the next. Just because school isn’t for you doesn’t mean you’re not smart and can’t make a good living,” says Knudsen.

Work/Leisure Time Tilt

How does Knudsen balance work and leisure time? That has taken a lot of practice, says Knudsen. “But learning to say ‘no’ has been the key to that. It’s been difficult to learn that, especially being in business for myself. Even some of my longest, best customers have helped me learn this. It has been truly difficult to tell them no at times. I don’t do it often, but it happens, even so they are still my loyal customers. I’ve discovered that is the key to not having my business/schedule own me and for me to own my business/schedule. There is a right time and a wrong time to say no, but it takes practice to learn those moments to help maintain balance in life,” says Knudsen.

Social media is big for Knudsen (@907plumber on Instagram). He has just gotten into social media the last couple years and overall, he says it has been wonderful. “The Instagram community is amazing IMO. Big shout out to the IG community you all ROCK!”

Social media is big for Knudsen (@907plumber on Instagram). He has just gotten into social media the last couple years and overall, he says it has been wonderful. “The Instagram community is amazing IMO. Big shout out to the IG community you all ROCK!”

Knudsen was actually feeling burnt out after his second shoulder surgery and contemplating trying something different for work— not trade related. Since Instagram has been such an amazing thing because it truly brought new life into his plumbing career. All the positive feedback from people all over the country and world has impacted him in a way he has not experienced before.

The growing of the followers, winning giveaways, connecting with others who do the same things he is passionate about everyday has brought a new shining light into his life, and for that, he is forever grateful. “I’ve learned so many new things through Instagram and it grows every day. It also has helped give me more of a sense of accountability and confidence I didn’t have before. I cannot believe people want to watch little ole’ me doing my thing, but I guess they like it, and being a service provider, I like to give people what they want. Additionally, If I can encourage or motivate someone to become a better version of themselves so they can experience a better quality of life and for all who they come in contact with, that is a true blessing,” says Knudsen.

Physical Fitness

Speaking of the shoulder injury and a demanding skilled trade, Knudsen puts a heavy emphasis on fitness. “I have only really incorporated fitness into my regular routine in the last several years and I have noticed tremendous benefits. Three years ago, I had surgery on my left shoulder for torn rotator cuff and torn bicep and four years before that I had the same surgery on my right shoulder. I’ve had to do quite a bit of physical therapy to get my shoulders back in working condition. I’ve also developed some tendonitis in my elbows in the past couple years. I’ve done several sessions with a physical therapist for my elbows. The therapist essentially told me that my poor posture was contributing to my elbow pains.

So now I’ve added regular fitness to maintain strength in my shoulders and core to reduce fatigue and improve posture during the day. A good portion of my exercises also incorporate strengthening muscles for good posture to reduce added stress on shoulder, elbow and wrist joints. We are constantly working on stuff right in front of our chest causing poor posture and unbalanced muscle development. This leads to fatigue, joint soreness and injuries.

So now I’ve added regular fitness to maintain strength in my shoulders and core to reduce fatigue and improve posture during the day. A good portion of my exercises also incorporate strengthening muscles for good posture to reduce added stress on shoulder, elbow and wrist joints. We are constantly working on stuff right in front of our chest causing poor posture and unbalanced muscle development. This leads to fatigue, joint soreness and injuries.

“We are working in awkward positions, pushing, pulling, lifting, twisting, bending. When we are in our younger years it seems that the need for fitness is not very important. Our bodies are fresh and more resilient but the longer we are in the trades the more wear and tear on the body happens, especially after 20+ years in the field. Fitness helps increase on the job performance, stamina, reduces potential for injury, helps with mental health and focus as well.

My goal is to maintain my ability to work in the field efficiently for many years to come. Hopefully my post about fitness helps some tradespeople to avoid injuries and discomfort while adding new vigor to their work and personal life,” says Knudsen.

In addition to performing better on the job, that dedication to fitness allows Knudsen enjoy the array of outdoor activities that Alaska has to offer, which include fishing for salmon and halibut, boating in the numerous sounds, inlets, bays, lakes, rivers and ocean all around Alaska, hiking, camping, wildlife viewing, exploring, snowboarding, snowmobiling, ATV adventures.

In addition to performing better on the job, that dedication to fitness allows Knudsen enjoy the array of outdoor activities that Alaska has to offer, which include fishing for salmon and halibut, boating in the numerous sounds, inlets, bays, lakes, rivers and ocean all around Alaska, hiking, camping, wildlife viewing, exploring, snowboarding, snowmobiling, ATV adventures.

“I love outdoor activities. Much of my spare time has been spent outdoors. For many years boating, camping and fishing all around Alaska was my summer time activity. Then snowmobiling and snowboarding in the winter. I’ve had the wonderful opportunity to see some of the most beautiful places and scenes Alaska has to offer while enjoying these activities.

And it’s that Alaska mystique I spoke of earlier. When asked when was the last time Knudsen said it was a great day? “I feel like it was somewhere around a week ago driving. It was just one of those days where it was crisp, clear beautiful weather, and the music was right. Thinking about all the people, experiences and moments that make me feel grateful to be alive; to have an opportunity to get to see the future unfold in front of me.”

Milwaukee, Wis. — Caleffi North America, Inc. announced the appointment of Sharon Alexander to the position of brand marketing manager. She will work closely with our sales and media networks and be responsible for advertising, public relations, trade merchandising, trade exhibitions and promotion development. Alexander has been involved in marketing within the heating, plumbing and Read more

Milwaukee, Wis. — Caleffi North America, Inc. announced the appointment of Sharon Alexander to the position of brand marketing manager. She will work closely with our sales and media networks and be responsible for advertising, public relations, trade merchandising, trade exhibitions and promotion development.

Milwaukee, Wis. — Caleffi North America, Inc. announced the appointment of Sharon Alexander to the position of brand marketing manager. She will work closely with our sales and media networks and be responsible for advertising, public relations, trade merchandising, trade exhibitions and promotion development.

Alexander has been involved in marketing within the heating, plumbing and solar industry for over 18 years. Before joining Caleffi, she spent 11 years as marketing manager at Hot Water Products headquarters (Milwaukee, Wis.) and 7 years with Solar Service Inc. (Niles, Ill.). She holds a bachelor’s degree in social science from North Central College (Naperville, Ill.) and marketing strategy certification from Johnson Graduate School of Management (Cornell University).

“I have always deeply admired Caleffi’s commitment to total product quality, exceptional technical expertise and guidance, as well as their innovative marketing efforts,” said Alexander. “I am overjoyed to join the team and help Caleffi continue its unique brand story throughout North America.”