Classes to be held in Colorado and New Hampshire Viega, LLC has announced its Fall 2019 lineup of courses at its seminar centers in Broomfield, Colo., and Nashua, N.H. The offerings include topics from radiant design and LoopCAD software to press technology. With two fully equipped state-of-the-art seminar centers, Viega is an industry leader in Read more

Radiant

Classes to be held in Colorado and New Hampshire

Viega, LLC has announced its Fall 2019 lineup of courses at its seminar centers in Broomfield, Colo., and Nashua, N.H.

The offerings include topics from radiant design and LoopCAD software to press technology. With two fully equipped state-of-the-art seminar centers, Viega is an industry leader in supporting the trades and helping contractors become more versatile, skilled and efficient. To date, more than 40,000 people, from self-employed contractors to employees of large firms, have taken courses at the centers.

The classes are taught by experts with years of experience in the field and offer ample hands-on experience. Attendees leave with skills and knowledge that will show immediate benefits on the job.

Training seminars are listed below:

Radiant Design, Piping and Controls

Oct. 1-3, Nashua, N.H.

Dec. 4-6, Broomfield, Colo.

Covers design theory and practice, piping arrangements and control strategies. Includes hybrid systems, multiple temperature piping arrangements and system component placement.

LoopCAD

Oct. 29-30, Nashua, N.H.

Sept. 23-24 and Nov. 11-12, Broomfield, Colo.

How to use LoopCAD software for radiant design and layouts. Covers heat loss, drawing layout, material selection and snow melt.

Commercial Piping Solutions

Oct. 8-9 and Dec. 3-4, Nashua, N.H.

Oct. 2-3, Broomfield, Colo.

Covers Viega systems and products and their appropriate uses. Includes PureFlow, ProPress and MegaPress; hybrid systems; installation techniques; project savings; hands-on installation and competitive information.

Hydronics 101 & Radiant Systems

Oct. 22-23, Broomfield, Colo.

Provides a basic understanding of how hydronic systems work. Topics include methods of heat transfer, piping materials and components, control strategies and installation methods.

Carbon Steel Press Technology

Oct. 15, Nashua, N.H.

Covers the use of carbon steel press systems for residential, commercial and industrial piping applications.

Stainless Steel Press Technology

Nov. 14, Nashua, N.H.

Covers the use of stainless steel press systems for commercial and industrial plumbing, heating and piping applications. Properties and chemical compatibility of 304 and 316 stainless steel will be covered.

For more information and to register, click here.

Mechanical Hub Media ProStaff Director Eric Aune chatted with Lee Browning, BIM and Estimation Supervisor at Uponor’s North American headquarters in Minnesota to discuss how Uponor’s Estimation and BIM services provides solutions for engineers and contractors. Onsite Jobsite Video: Uponor’s BIM and Estimation Services Read more

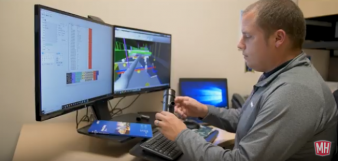

Mechanical Hub Media ProStaff Director Eric Aune chatted with Lee Browning, BIM and Estimation Supervisor at Uponor’s North American headquarters in Minnesota to discuss how Uponor’s Estimation and BIM services provides solutions for engineers and contractors.

Mechanical Hub Media ProStaff Director Eric Aune chatted with Lee Browning, BIM and Estimation Supervisor at Uponor’s North American headquarters in Minnesota to discuss how Uponor’s Estimation and BIM services provides solutions for engineers and contractors.

Onsite Jobsite Video: Uponor’s BIM and Estimation Services

While PEX has been used for more than 40 years in radiant heating applications, it’s now getting more traction in commercial hydronic heating and cooling applications as well. Contractors and engineers are beginning to spec and install PEX for distribution piping to various terminal units, such as fan coils, reheat coils, heat pumps, baseboard radiators Read more

While PEX has been used for more than 40 years in radiant heating applications, it’s now getting more traction in commercial hydronic heating and cooling applications as well. Contractors and engineers are beginning to spec and install PEX for distribution piping to various terminal units, such as fan coils, reheat coils, heat pumps, baseboard radiators and chilled beams.

While PEX has been used for more than 40 years in radiant heating applications, it’s now getting more traction in commercial hydronic heating and cooling applications as well. Contractors and engineers are beginning to spec and install PEX for distribution piping to various terminal units, such as fan coils, reheat coils, heat pumps, baseboard radiators and chilled beams.

However, while PEX is thoroughly tested and proven in the field, it can sometimes be misunderstood. Many wonder if a plastic pipe can really compete with, let alone outperform, metallic piping in these types of applications.

So, to make it easy, I’ve outlined a few important facts you should know before installing PEX in a hydronic distribution piping application.

All PEX is not the same

Professional PEX products fall into three categories: PEX-a, PEX-b and PEX-c. Of those three, PEX-a, manufactured using the Engel Method, has the highest degree of consistent crosslinking — at 80 percent. This produces a pipe that is more flexible and more durable with thermal and elastic memory properties.

Understanding thermal and elastic memory

Thermal memory is the ability to repair accidental kinks in the PEX-a piping with a controlled heating source, such as a heat gun. The controlled heat quickly eliminates the kink in minutes, while the pipe is restored to its original durability.

Elastic memory refers specifically to how PEX-a piping will quickly return to its original dimensions after expansion. This allows the use of the exceptionally strong, ASTM F1960 fitting connection.

In creating a PEX-a connection, the installer uses a specially made expansion tool to enlarge the diameter of the pipe, so that a fitting with a slightly larger internal diameter can be inserted. The pipe quickly compresses over the fitting, creating a durable connection that actually strengthens over time.

Just as important: Because the fitting diameter is a bit larger than the pipe diameter, “dry-fit” pipe connections are physically impossible. This eliminates the problem when an installer neglects to solder or glue a fitting in a copper or CPVC system, resulting in costly leaks inside the walls of a completed project. An ASTM F1960 fitting requires the connection be fully made, permitting quick visual confirmation.

The difference with expansion fittings

Unlike with metallic pipe, an expansion fitting is actually the strongest part of a PEX-a system. It will not leak. In fact, pull testing shows that even 3,000 pounds of force with over 13 inches of displacement does not compromise the integrity of the ASTM F1960 PEX-a connection. In all likelihood, there would be a catastrophic failure of the building structure before enough force is applied to break that connection.

Using hangers and supports

PEX-a pipe can be hung at similar intervals as metallic pipe. It’s true that other plastic piping systems typically require supports every 32 inches. Some manufacturers, however, offer PEX-a pipe supports — a galvanized steel channel that provides continuous support in suspended-piping applications. This support allows PEX-a to behave just like a metallic piping system in many ways, including hanger spacing: ½-inch and ¾-inch PEX-a pipe can be hung at 6-foot intervals; 1-inch through 3-inch pipe, at 8-foot intervals.

Addressing expansion and contraction

The PEX-a pipe support controls the natural expansion and contraction that occurs as the piping heats and cools. Used in conjunction with manufacturer-recommended installation practices, the pipe support allows PEX-a to undergo an expansion rate equal to or, in some cases, less than that of copper.

Temperature and pressure considerations

PEX-a is rated for continuous operation at 200°F at 80 psi. Any hydronic application with water temperatures at or below this value is perfectly applicable for the product.

Fire-resistant construction ratings

PEX-a is ASTM E84-rated for flame- and smoke-resistance inside a non-ducted, return-air plenum. This also applies to fire stopping. For more information regarding these listings, please contact the manufacturer.

Codes and standards compliance

PEX-a is compliant with all codes and standards that pertain to it, be they in the International family (IBC, IRC, IMC, IPC) or the Uniform family (UMC, UPC, CPC) of U.S. Codes.

To learn more about Uponor’s solutions, visit uponor.com.

Kim Bliss is the content development manager at Uponor. She can be reached at kim.bliss@uponor.com.

Kim Bliss is the content development manager at Uponor. She can be reached at kim.bliss@uponor.com.

MrPEX ® Composite Radiant Manifold is made from a durable high performance plastic designed to withstand high temperature and pressure. The manifold exceeds the oxygen diffusion standard DIN 4726 and is completely corrosion resistant. The manifold comes partially assembled as a complete kit. Plastic cap on the return valve can be removed to accommodate a Read more

MrPEX ® Composite Radiant Manifold is made from a durable high performance plastic designed to withstand high temperature and pressure. The manifold exceeds the oxygen diffusion standard DIN 4726 and is completely corrosion resistant.

MrPEX ® Composite Radiant Manifold is made from a durable high performance plastic designed to withstand high temperature and pressure. The manifold exceeds the oxygen diffusion standard DIN 4726 and is completely corrosion resistant.

The manifold comes partially assembled as a complete kit. Plastic cap on the return valve can be removed to accommodate a valve actuator. The branches accommodate all MrPEX ® EK20 compression fitting assemblies to connect tubing up to 5/8″. Single, 2 loop, 3 loop, and 4 loop add-on supply and return manifold sections and other accessories are sold separately to allow for easy add-on.

For more info visit MrPEX

I recently installed my first Lochinvar Noble combi-boiler, it was a replacement upgrade from a failed dual purpose tank heater supplying heat to both garage and basement radiant floors. This model was the 199K Btu running on natural gas, vented in 3″ (factory outlet size on boiler) with a rating of 95% AFUE. Lochinvar specs Read more

I recently installed my first Lochinvar Noble combi-boiler, it was a replacement upgrade from a failed dual purpose tank heater supplying heat to both garage and basement radiant floors.

This model was the 199K Btu running on natural gas, vented in 3″ (factory outlet size on boiler) with a rating of 95% AFUE. Lochinvar specs the domestic delivery to be 4.8 gallons per minute (77F rise, NKC199 model only) and that was the deciding factor in selecting this model. With a 10:1 turndown ratio the heating capacity of this unit is right-sized for the load even though its capable of much more. Domestic production takes president in this situation.

The Noble boiler is equipped with Lochinvar’s SMART CONTROL and features an intuitive setup wizard to guide contractors through programming parameters quickly and easily. The backlit, user-friendly LCD display provides diagnostic information and system status in plain English, not codes.

Of course this unit is my first of the model line and has only been in operation for about a week as of this posting so I have no long term experience with performance and reliability but based on my experience with the Knight and Cadet models I have relatively high expectations for this one to serve my client well.

Here’s a link to some video I took while installing the system (Click the arrows to advance thru the video clips):

https://www.instagram.com/p/BbPTM8QBHu9/?utm_source=ig_share_sheet&igshid=uf9c5lrmm0y4