The Pennsylvania Petroleum Association (PPA) has become a leading source of knowledge and training expertise for HVAC professionals throughout the Northeast and Mid-Atlantic regions. One of their most popular courses, Advanced Hydronics, is offered as a one-day course at PPATEC—the association’s Technical Education Center in Middletown, Pa.—one to three times yearly, and as a half-day Read more

training

The Pennsylvania Petroleum Association (PPA) has become a leading source of knowledge and training expertise for HVAC professionals throughout the Northeast and Mid-Atlantic regions.

One of their most popular courses, Advanced Hydronics, is offered as a one-day course at PPATEC—the association’s Technical Education Center in Middletown, Pa.—one to three times yearly, and as a half-day session 4 to 6 times yearly by instructor/trainer Dave Holdorf. In October ’23, he returned to PPATEC (his 5th visit in ’23) to lead their advanced hydronics course. Holdorf not only wrote the book used for the multi-day course, but also designed the laboratory they’re used for hands-on training.

Dave Holdorf giving his in-person Adnvaced Hydronics course at PPATEC.

Holdorf’s become a cult phenomenon and is now regarded as one of the nation’s best trainers of hydronic trade professionals.

His book, Advanced Hydronics, published by NORA (National Oilheat Research Alliance), is a favorite resource among hydronic system technicians.

An outgoing and amusing educator, Holdorf is also a Taco Comfort Solutions’ Product and Applications Instructor—East, a role that routinely puts him in the “bullpen” with two other equally-engaging and amusing hydronic experts, John Barba and Rick Mayo. Their “Taco After Dark” (see sidebar) webinar was hosted by PPATEC on October 4, with Holdorf as the emcee.

Holdorf has been in the hydronic industry for 25 years, specifically in the radiant heating side of the business for the better part of his career. Holdorf was presented with the “Dan Holohan Instructor of the Year” award in 2020.

“I love what I do—and the best of it happens when I’m among an group of trade professionals. We laugh, swap stories and learn. What could be better?” asked Holdorf.

‘Mecca’ for Hydronics Training

During his trips to PPATEC’s growing facility, Holdorf enjoys the training spotlight typically focused on PPA’s other HVAC instructors, including their very own Lead Technical Trainer, Alan Mercurio—one of the most popular trainers in the Northeast region.

Alan Mercurio (c), doing what he loves to do — teach.

Trade pros flock to the facility near Harrisburg as something of a “Mecca” for HVAC technicians eager to deepen their understanding of installation and service techniques and theory. Visiting trainers at the PPATEC facility, many of whom make multiple trips each year to the facility, include Brian Kiernan of Energy Kinetics, Bruce Graham of Carlin/Hydrolevel, Curtis Martin or R. W. Beckett, Joe Sacco of Riello, and Ron Beck, Training Manager emeritus, U.S. Boiler.

Advanced Hydronics

In October, Holdorf spent several days teaching advanced hydronics, much of it from his book, to jam-packed trade pro audiences at PPATEC. There wasn’t a spare seat in the classroom.

“We love it when Dave comes to teach. He’s one of our most popular trainers,” said Mercurio. “He has a special way of keeping a classroom full of technicians engaged and eager to learn.”

Contractors arrive at PPATEC for in-person training.

According to Holdorf, anyone can put together a bunch of parts and call it a hydronic heating system. But are those parts and pieces selected properly and being used as they were intended? That was the focus of the advanced hydronics course, intended to take attendees through the decision process, prior to system design. The goal: to guide deliberate, informed system development, startup and commissioning.

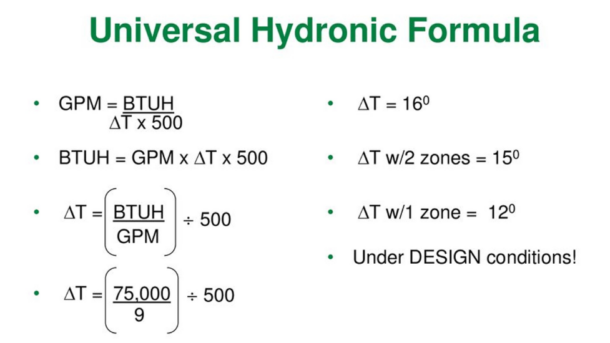

Of course—you’ve heard it many times before from these savvy hydronic-ians: every good system begins with a heat load calculation. “The math isn’t difficult, but it’s necessary,” assured Holdorf. Whether in class, or speaking to a Taco After Dark audience, Holdorf and Barba steer participants toward the Universal Hydronic Formula.

In essence:

• GPM (gallons per minute, or required flow) = BTUH ÷ ∆T and multiplied by 500

• ∆T is the temp drop across the piping circuits (difference between supply + return)

• Why the 500?

“Well, it’s a math shortcut,” he explains. The number stems from the weight of one gallon of water (8.33 lbs.) x the number of minutes in an hour x 1, or . . .

8.33 x 60×1 = 499.8 . . . and 500 is close enough.

To provide comfort within a home, a well-designed and installed hydronic system provides proper thermal energy transfer (or the ability “to carry the BTUs”) to all points of distribution. For residential systems, Holdorf recommends at 20°∆T.

From there, Holdorf and Barba led the live and online audience through several explanations that tie to this formula:

• Glycol is thicker and doesn’t carry as much energy (and its pH should be checked routinely)

• Proper flow rate for a load calculated at 82,401 BTUs (a decent-sized home):

GPM = BTUH ÷ (∆T x 500), so . . .

GPM = 82,401 BTUs ÷ (20 x 500)

GPM = 8.2

From there, Holdorf leads his audience through the basics of transporting that heat outward for distribution, and back to the boiler to be reheated:

• ¾” copper will move 2-4 GPM

• 1” pipe will move 4-9 GPM – the right size for the 8.2 GPM calculation above; typically, this is all that residential systems require. Large pipe is required for “starter castle” homes and commercial purposes.

• 1-1/4” pipe allows movement of 8-14 GPM

• 1-1/2” permits 14-22 GPM

Too much flow creates velocity noise. Insufficient flow makes it difficult to purge entrained air from the water. The challenge of air within the hydronic solution—whether water, or glycol—became the segue to air elimination. And, with Holdorf and Barba guiding the conversation, it becomes a fascinating topic: one you can easily find on the Taco After Dark website: https://www.tacocomfort.com/training/online-training/taco-after-dark/ (take your cursor to the Oct. 4 broadcast).

Heat Emitters; and Pipe Sizing, Air Control and Pumping Away

Once you know the BTUH heating load, you can now get down to the business of adequately sizing heat emitters. Typically, the choices are: fin-tube baseboard, cast-iron and panel-type radiators, radiant floor heating +/or hydro-air.

From there, Holdorf and Barba discussed the use of cast iron and mod-con boilers, and air-to-water heat pumps. They also illustrated how to interpret output and design charts so installers can match heat emitters to the water temperatures produced by the heat plant

Holdorf and Barba also spoke about how to properly size a boiler header and distribution piping based on the BTUH load.

A few other points stirred lively conversation among participants:

- Hydronic system components, what goes where and why

- Boiler size

- Pipe size

- Near boiler piping—best practices and options

- Finally: controls

“I’ve now learned from Dave [Holdorf] on a couple of occasions at PPATEC,” said Eric Love, a technician with HB Home Services, a division of H. B. McClure Company, based in Harrisburg. “He’s a terrific instructor, and very entertaining. He’s one of many reasons I now look forward to more training there.”

Free Online Training for Boiler Heating Systems

Taco After Dark – LIVE from PPATEC, 10-4-23, on Mechanical-Hub

Weekly, Wednesday evening Taco After Dark webinars have risen to the top as the nation’s most popular online source of live (and YouTube-archived) hydronics knowledge and expertise.

The focus of Taco After Dark—practical, real-world solutions to the challenges hydronics professionals face every day.

Mechanical-Hub

The, um, “Magical Mystery Tour” of Taco After Dark began early in the Covid pandemic. Holdorf and fellow Taco trainers John Barba and Rick Mayo made a call to Mechanical-Hub’s managing partners – hoping to offer an exciting online training platform. Long story short: Taco and th’ Hub worked together to engaged both of their trade pro audiences. These days, all of the Taco After Dark broadcasts are recorded onto Mechanical-Hub’s YouTube page.

As th’ Hub’s Editor, John Mesenbrink, so succinctly said, “Online learning brings us together.” And that’s exactly what happened when Holdorf went live with the “Taco After Dark” broadcast from 7-9 pm on October 4 from PPATEC’s newest hydronic lab.

As th’ Hub’s Editor, John Mesenbrink, so succinctly said, “Online learning brings us together.” And that’s exactly what happened when Holdorf went live with the “Taco After Dark” broadcast from 7-9 pm on October 4 from PPATEC’s newest hydronic lab.

Before the online audience joined in to learn, and to contribute, Holdorf enjoyed connecting with show co-host John Barba—Taco’s lead residential instructor —and special guest Dave Yates who was the owner (now retired) of York, PA-based F. W. Behler, Inc., a full-service mechanical contracting firm. Talk about a forum for fun! These guys could make you laugh through the last, post-apocalyptic hour of mankind.

In the lab’s studio, Holdorf was joined by several of PPA’s staff and a gaggle of students—advanced installers and service pros among them—for the fun, fast-paced training session. The evening’s broadcast topic: hydronic piping and circulation.

If you haven’t yet experienced the style of humor and education—the clash of laughter and learning that’s unique to Taco After Dark—you owe it to yourself to check it out. Don’t take my word for it—all of their sessions are archived; the stored broadcasts are almost as much fun as the live productions.

If you haven’t yet experienced the style of humor and education—the clash of laughter and learning that’s unique to Taco After Dark—you owe it to yourself to check it out. Don’t take my word for it—all of their sessions are archived; the stored broadcasts are almost as much fun as the live productions.

Holdorf, true to form for the broadcast, took just a slice of the full-day residential hydronics training class, served with a healthy measure of merriment. He and Barba—often in concert with Taco’s other trainers, Rick Mayo, Rich Medairos and Brett Zerba (Medairos + Zerba focus their efforts on commercial hydronic systems)—deftly held the attention of live and online trade pros.

Enraptured audience

It would be quite a challenge to educate and entertain a large, mixed group of hydronic techs, but not for Holdorf and Barba with just the right mix of antics, humor and trade secrets.

One young technician in the live audience for the PPATEC Taco After Dark broadcast was Owen Kunder, a mid-20s service and installation tech with Stevens, Pa.-based Vertex Mechanical. Kunder drove more than 30 miles to attend the live event.

“I haven’t had much training for boiler work yet, so being there for the broadcast was really exciting,” he said. “I learned a lot. One thing that stuck out was hearing Dave talk about system design, and the differing PSI levels that vary with building height. It was fascinating.

“I’ve been installing Taco components since I was 16, but wasn’t aware that they offered air eliminators,” he added. “I really enjoyed myself and will be sure to catch more Taco After Dark broadcasts.”

Kunder was soon joined by fellow Vertex installer, Jared Fox. After greeting each other, they spotted the boxes of pizza and then settled in for the “show.” Meanwhile, the live audience was admiring the immaculately-installed hydronic system that, two years earlier, Fox installed.

“This was a first experience for me with Taco After Dark,” said Fox. “I wasn’t sure what to expect, but when Dave got rolling, I was very impressed.

“[Holdorf] offered insights into why things are done certain ways when designing and installing hydronic systems,” continued Fox. “I learned a lot in a short period of time; he gave me a deeper understanding of concepts and practices that I thought I knew a lot about. I was also learning from his answers to my questions—and especially the questions of others. There’s always new stuff to learn, and this experience was super valuable.”

“Holdorf leaves you with a good, lasting impression,” said Eric Love, a technician with HB Home Services. “I’ll always recall that a circulator doesn’t move water—it creates a pressure differential between the inlet and the outlet.” Oh, the things that define the uniqueness of hydronics!

Remaining LIVE/on-location presentations of Taco After Dark

October 25: Flow, Heat and the Finer Points of Circulator Selection

The next step in building a great hydronic system is understanding the interrelationship between BUTH, flow, pressure loss (known as head loss) and pipe sizing. All of those ingredients go into proper circulator selection.

In this class, you’ll learn why there’s no such thing as one circulator for all applications, and how our industry actually has a chronic circulator oversizing problem. And we’ll also start the discussion on variable speed ECM circulators and why there’s no such thing as a circulator that sizes itself.

ON-SITE & ONLINE

New England Institute of Technology

1 New England Tech Blvd

East Greenwich, RI 02818

Wednesday, Oct. 25

7:00 pm EDT

November 1: ECM Circulator Essentials

ECM stands for Electronically Commuted Motor. And those three little letters are transforming residential hydronics. But do we really know what we need to know about how these remarkable little devices work?

Variable speed technology can do wonders for the modern residential hydronic system, but they’re not magic. They don’t size themselves and they don’t take the thinking out of circulator selection, no matter how many times you press that AUTO button. In this session, we’ll dispel the many myths and common falsehoods about ECM circulators. And we’ll show you the real value of these things will help you create the most efficient system possible for your customers.

7:00 pm EDT

Circulators or Zone Valves

If you were King of Hydronics and you could dictate to the industry how to zone a system, would you insist on one circulator per zone, or would you rule in favor of one circulator and zone valves?

It’s an age-old question, and in this session of Taco After Dark we’ll examine the pros, cons, realities, and myths of both options. And by the time the hour is up, we’ll provide you with the ultimate and definitive answer as to which one is better and why.

Wednesday, Nov. 8

7:00 pm EDT

November 15: Air-To-Water Heat Pumps and Low Temperature Hydronics

With the movement to “beneficial electrification” well underway, air-to-water heat pumps are becoming a factor in modern residential hydronics.

In this program, we’ll discuss how these things work, what they can (and can’t) do, and how to get into this rapidly growing business. You’ll also learn about the new Taco System M air-to-water heat pump and its unique capabilities.

ON-SITE & ONLINE

Johnson College

3427 North Main Ave.

Scranton, PA 18508

7:00 pm EDT

Register

Attendees may register for each session individually, and each program will be recorded and archived for later viewing. Each session qualifies installers for one PDH credit. (YOU MUST ATTEND ONE OF THE LIVE WEBINAR SESSIONS (NOT THE RECORDED SESSION IN ORDER TO RECEIVE THE PDH CERTIFICATE.) The link to the PDH certificate, along with a link to the recorded webinar session, will be emailed to you approximately 24 hours after the end of each webinar session.

David Holdorf

Residential Trainer, Eastern Region, Taco Comfort Solutions

Holdorf has been in the hydronic industry for 25 years, specifically in the radiant heating side of the business for the better part of his career. Starting out in the technical support/design role and then took over as Engineering Manager overseeing the Technical Support and Design Department. Later he took a position as a Field Technician; supporting training, designing, installing and troubleshooting.

John Barba

Director of Training, Taco Comfort Solutions

John Barba has been in the plumbing heating industry most of his life, growing up in his family’s plumbing and heating business in Harvard, MA. John’s practical experience includes everything from ditch digging and drain cleaning to boiler piping and PEX slinging, as well as business management and contractor sales. Since 1995, John has trained over 30,000 contractors on the fine art and subtle science of hydronic heating design and installation through highly interactive, entertaining and informative seminars.

He is the 2012-2014 recipient of the Carlson-Holohan Industry Award of Excellence, and was recently named the industry’s Best Trainer for 2015 by AHRI News Magazine.

Rick Mayo

Western Product and Application Instructor, Taco Comfort Solutions

Rick started his career in the hydronic heating industry as a plumber in 1977. In 1981, he transitioned into a wholesale role. Over the next 21 years, he worked his way up to a regional heating manager and left to pursue a training/technical support position with Uponor-Wirsbo. Seven years later, Rick took a western regional sales manager/corporate trainer role with Triangle Tube/ACV. Since joining Taco in 2015, Rick has made an impact as the Western Product and Application Instructor through his training that stretches from Alaska to San Diego, as well as four provinces in western Canada.

Richard Medairos

Director of Engineered Products and Systems Training

Medairos is a Senior Systems Engineer and Director of Commercial Training at Taco Comfort Solutions. He has over forty years of experience with demonstrated expertise in engineering, project management and planning. Throughout his career, he has worked on projects with major clients such as NASA’s Kennedy Space Center, Disney World, Universal Studios Florida, Boston University, Rhode Island School of Design, First Data Corporation, and Taco’s Innovation & Development Center.

Brett Zerba

Applications Engineer, Taco Comfort Solutions

Zerba is an Application Engineer at Taco Comfort Solutions with over twenty years of experience at the company. He graduated with his Bachelor of Science in Mechanical Engineering from the University of New Hampshire in 1981, and in 2003 he earned his Master of Business Administration from Johnson & Wales. Mr. Zerba has demonstrated his skill and expertise in the field of hydronic systems as an ASHRAE and Hydraulic Institute member.

Interplay Learning, the leading provider of immersive skilled trades training, announced today a strategic training partnership with PipeDreams, an innovative, tech-forward home services provider. The collaboration with Interplay will accelerate PipeDreams’ ability to acquire, integrate, and grow new partnerships by offering tech-forward training, including hands-on 3D simulations. With a focus on building meaningful trade careers, this Read more

Interplay Learning, the leading provider of immersive skilled trades training, announced today a strategic training partnership with PipeDreams, an innovative, tech-forward home services provider. The collaboration with Interplay will accelerate PipeDreams’ ability to acquire, integrate, and grow new partnerships by offering tech-forward training, including hands-on 3D simulations. With a focus on building meaningful trade careers, this partnership will empower 100+ valued technicians of all levels with the tools to rapidly hone their technical skills, elevate safety standards, and reliably serve customers across partner companies.

One of the pivotal aspects of this collaboration is PipeDreams’ vision to establish an apprenticeship program through PipeDreams University, with Interplay’s online courses at its core. The training approach will encompass 3D simulations, videos, quizzes, and hands-on learning, providing PipeDreams’ technicians with a well-rounded and engaging educational experience with pathways to industry certifications like EPA 608 and NATE.

“Our commitment to developing our service team has been a driving force throughout my journey with the company,” said Grace Underdahl, Training Program Lead at PipeDreams. “We’re creating a holistic training platform that supports development in every role, from general managers to HVAC service technicians. Interplay Learning’s technology perfectly matches our vision to be technology-forward and empower our technicians in a safe and scalable format.”

Given the growing skills shortage, PipeDreams also sees Interplay’s training as a powerful recruitment tool. By making trade careers more accessible, they can attract more technicians eager to embark on a journey of learning and growth within their local markets.

Isabel Sopoglian, Head of Business Operations at PipeDreams, underlined the significance of training on company growth, stating, “Training is a key component of attracting and retaining our employees and increasing the quality of work we deliver. We want our employees to feel our investment in them. It’s a very important aspect of our growth, and our collaboration with Interplay Learning is crucial to this strategy.”

In addition to supporting recruitment and retention efforts, Underdahl and Sopoglian anticipate Interplay’s training to enhance existing operations, equipping technicians with more effective troubleshooting skills and improving ramp time and callbacks for new technicians.

“Interplay is proud to partner with PipeDreams, a mission-aligned company leading with technological innovation and transforming how training is done in the home services industry,” said Doug Donovan, CEO of Interplay Learning. “Our shared mission is to foster successful business partnerships and empower PipeDreams’ workforce with the skills and knowledge they need to thrive in their careers.”

PipeDreams offers a range of residential HVAC and plumbing services through a growing partner network, including Albert Nahman Plumbing, Heating, and Cooling, Wighton’s Plumbing, Heating, & Air Conditioning, Perry Heating, Cooling, & Plumbing, TNT Home Services, Clout Home Services, Ace Pelizon Plumbing, Paso Robles Heating and Air and Plumbing the Bay.

What: A. O. Smith, a leader in water heating and water treatment, will use its September and October A. O. Smith University classes to educate professionals on its broad line of gas and electric water heating solutions. A. O. Smith University will continue to offer its monthly virtual classes in addition to its popular in-person Read more

What:

A. O. Smith, a leader in water heating and water treatment, will use its September and October A. O. Smith University classes to educate professionals on its broad line of gas and electric water heating solutions. A. O. Smith University will continue to offer its monthly virtual classes in addition to its popular in-person training.

The September in-person class will take place Sept. 12–14 at the A. O. Smith training center in Ashland City, Tennessee. The course will cover installation, maintenance and installation-related troubleshooting for commercial gas, commercial electric and tankless gas units. Individuals can register online for in-person classes, but please note registration is not guaranteed until participants receive a confirmation from A. O. Smith. For more information on virtual and in-person training classes, visit www.university.hotwater.com/virtual-campus/.

When:

Sept. 5, 8:00 a.m. CDT Residential Heat Pump Contractor Training

Sept. 6, 8:00 a.m. CDT Tankless Contractor Training

Sept. 12, 8:00 a.m. CDT In-Person Contractor Training

Sept. 13, 8:00 a.m. CDT In-Person Contractor Training

Sept. 14, 8:00 a.m. CDT In-Person Contractor Training

Sept. 19, 8:00 a.m. CDT VOLTEX AL Heat Pump Water Heater Contractor Training

Sept. 20, 8:00 a.m. CDT Commercial Gas Contractor Training

Oct. 3, 8:00 a.m. CDT Residential Gas Contractor Class

Oct. 4, 8:00 a.m. CDT Tankless Single Heater Installations

Oct. 17, 8:00 a.m. CDT Residential Gas Power and Power-Direct Vent

Oct. 18, 8:00 a.m. CDT Commercial Electric Contractor Class

Oct. 31, 8:00 a.m. CDT Residential Electrical Contractor Training

Where:

A. O. Smith Customer Care Facility

106 Adkisson St

Ashland City, TN37015

Can a hydronic system effectively – and efficiently – provide heating, cooling, domestic hot water AND heat recovery ventilation in a residential home? John Siegenthaler, P.E., a favorite to the webinar series, will discuss design details, challenges and lessons learned from a from a recent project profile of a modern hybrid approach utilizing an air-to-water heat Read more

Can a hydronic system effectively – and efficiently – provide heating, cooling, domestic hot water AND heat recovery ventilation in a residential home? John Siegenthaler, P.E., a favorite to the webinar series, will discuss design details, challenges and lessons learned from a from a recent project profile of a modern hybrid approach utilizing an air-to-water heat pump system that checks all of the boxes during this 90-minute extended edition.

You’ll learn:

→ Back-up heating. When is it necessary?

→ Can a single 44 watt circulator supply all space heating flow for a 2,300 square foot house?

→ Does chilled water cooling and heat recovery ventilation require separate duct systems?

→ Can panel radiators operate at supply water temperature below 100 ºF on design days?

→ Where does an “extended manifold” piping system make sense?

→ How are 3-way diverter valves applied in air-to-water heat pump systems?

→ What are the advantages of multi-zone heating combined with single-zone cooling?

Siegenthaler is a seasoned industry leader and passionate teacher, eager to share his over 40 years’ experience in the understanding and proper application of water-based engineering principles with our audience. He is the principal of Appropriate Designs and a regular contributor to industry publications.

Coffee with Caleffi technical training webinars are free and intended for contractors, designers and wholesalers. A Certificate of Attendance is emailed to attendees following the webinar for continuing education consideration. Want to join us? Simply register today.

Residential heating contractors can hone their boiler technology and hydronic skills and knowledge by participating in a Weil-McLain® 2023 School of Better Heating training program this fall. The School of Better Heating program is an annual series of comprehensive condensing boiler technology training seminars from the leading North American designer and manufacturer of hydronic comfort heating systems. The Read more

Residential heating contractors can hone their boiler technology and hydronic skills and knowledge by participating in a Weil-McLain® 2023 School of Better Heating training program this fall. The School of Better Heating program is an annual series of comprehensive condensing boiler technology training seminars from the leading North American designer and manufacturer of hydronic comfort heating systems.

The Condensing Boiler Technology & Hydronic Fundamentals course will be available in one- and two-day sessions and feature seminars and hands-on training for condensing gas boilers, including Weil-McLain’s ECO® Tec Series 2 high-efficiency premium residential boiler. This year’s training schedule kicks off in Pittsburgh on September 12 and will continue through November at various locations in the Eastern and Central regions of the country, including:

- September 12 – Pittsburgh

- September 13 – Cleveland

- September 13-14 – Westchester County, N.Y. (Two-day session)

- September 19 – Stevens Point, Wis.

- September 21 – Milwaukee

- September 26 – Duluth, Minn.

- September 26-27 – New England / Raynham, Mass. (Two-day session)

- September 28 – Twin Cities, Minn.

- October 10 – Detroit

- October 12 – Cincinnati

- November 2 – Akron, Ohio

Each course will cover the following objectives:

- Hydronics basics and fundamentals

- Design, construction and operation of condensing boilers

- Proper installation, venting, piping and wiring, as well as set-up and programming of controls

- Boiler start-up, maintenance and troubleshooting

Registration for this year’s School of Better Heating classes is $99 for the one-day sessions and $199 for the two-day sessions, and includes reference materials, breakfast and lunch and a certificate of completion. For more information or to register online, visit www.weil-mclain.com/residential-training.