The 180,000-sq.-ft. plant in Shalersville, Ohio, will break ground in November 2023 and is expected to be operational in early 2025. Broomfield, Colo. — Viega recently announced that it will build a new manufacturing facility for its ProPress® and MegaPress® products in Shalersville, Ohio, about 40 miles southeast of Cleveland. Viega LLC President and CEO Read more

Viega

The 180,000-sq.-ft. plant in Shalersville, Ohio, will break ground in November 2023 and is expected to be operational in early 2025.

Broomfield, Colo. — Viega recently announced that it will build a new manufacturing facility for its ProPress® and MegaPress® products in Shalersville, Ohio, about 40 miles southeast of Cleveland. Viega LLC President and CEO Markus Brettschneider made the announcement.

“This is an exciting time at Viega, as our growth continues to prompt the expansion of our North American footprint,” said Markus Brettschneider, CEO and President of Viega LLC. “This new facility in Ohio, along with recent investments in our existing Kansas facility, further supports our growing demand and is part of Viega’s plan to increase North American production. We look forward to expanding our presence in this part of the country to further support our customers.”

The 80-acre parcel in Shalersville and the construction of the new plant represent an investment of approximately $200 million in Ohio. Viega’s business continues to grow in the U.S., and the additional plant will help support the increased demand for Viega products. It also aligns with the company’s sustainability goals, which include reducing the carbon emissions associated with importing products by manufacturing more items in the U.S. The new facility will be completely carbon neutral from the start, supporting the company’s long-term goal of achieving net-zero carbon emissions for all their plants by 2035.

“The expansion of our operations into Ohio shows our commitment to creating highly skilled jobs in the U.S.,” said Marki Huston, Head of Manufacturing for Viega LLC. “Our goal is to build more sustainable manufacturing processes and continue developing tomorrow’s workforce. With production scheduled to begin in early 2025, we expect to start hiring for positions as soon as January 2024, bringing more than 68 new jobs to the area over the next few years.”

Viega recently announced investments in new equipment for its McPherson, Kansas, manufacturing and distribution facility. In addition, Viega supports its customers and partners through distribution centers in Reno, Nev. and Carlisle, Penn., with more North American expansion planned for 2024 and 2025.

Viega worked with local, regional, and state organizations, including Team NEO, JobsOhio, Portage Development Board and the Shalersville-Streetsboro Joint Economic Development District on tax credit assistance and to select the 80-acre site. “We have a great manufacturing legacy, dedicated talent pool, and future-oriented industry resources to support Viega’s new operations,” said Team NEO Chief Executive Bill Koehler. “Along with JobsOhio and our local partners, we welcome Viega to the Northeast Ohio Region. We are confident they will thrive here.”

Viega plans to invest over $70 million in the next two years as part of its long-term strategy to expand U.S. manufacturing and support the needs of its North American customers. Broomfield, Colo. — Viega announced plans to expand its production capacity in McPherson, Kansas. The first wave of these investments is approximately $14 million Read more

Viega plans to invest over $70 million in the next two years as part of its long-term strategy to expand U.S. manufacturing and support the needs of its North American customers.

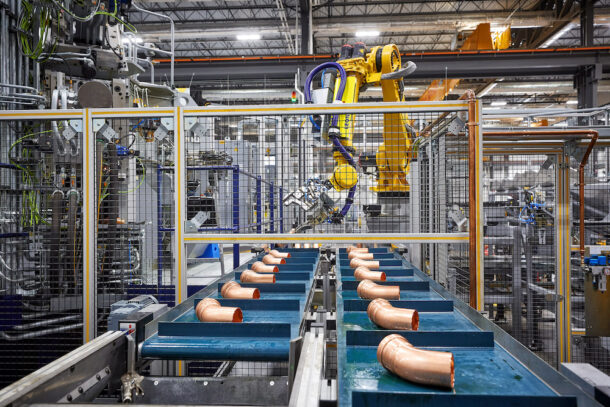

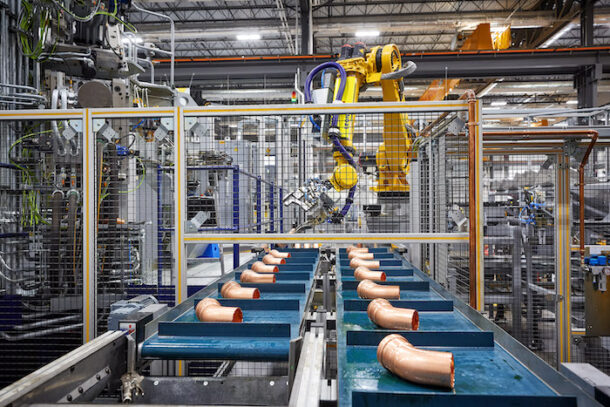

Broomfield, Colo. — Viega announced plans to expand its production capacity in McPherson, Kansas. The first wave of these investments is approximately $14 million and will increase the U.S. production of its industry-leading ProPress® products.

“As we continue to grow the business, we are bringing more production to the United States,” said Markus Brettschneider, CEO and President of Viega LLC. “These investments in our U.S. footprint will further support demand and leverage the talented U.S. manufacturing workforce, starting with the expansion of production capacity in Kansas.”

The McPherson manufacturing and distribution center is currently around 1 million sq. ft, with the facility more than doubling its footprint and workforce since opening in 2008. The new ProPress equipment is expected to be in production by the end of Q3 2023, with additional investments to come.

“We are proud to produce our fittings right here in Kansas. As we increase our U.S.-made products, we remain committed to creating highly skilled jobs in America, building out more sustainable manufacturing processes, and developing tomorrow’s workforce,” said Marki Huston, Head of Manufacturing for Viega LLC.

In addition to its McPherson, Kansas facility, Viega supports its customers and partners through distribution centers in Reno, Nev. and Carlisle, Penn., with further North American expansion planned for 2024 and 2025.

We had the great pleasure of having Brent Ridley on the Appetite for Construction podcast this week and as mentioned on the podcast, we wanted to share with you the Miracle Mechanical Project in Gainesville, Georgia. https://youtu.be/y99Ikwss5LY Run by husband-and-wife team, Brent and Kathleen Ridley, the Miracle Mechanical Project is dedicated to uplifting families and Read more

We had the great pleasure of having Brent Ridley on the Appetite for Construction podcast this week and as mentioned on the podcast, we wanted to share with you the Miracle Mechanical Project in Gainesville, Georgia.

Run by husband-and-wife team, Brent and Kathleen Ridley, the Miracle Mechanical Project is dedicated to uplifting families and communities by providing much-needed plumbing and HVAC repair at no cost to the recipient.

The team, along with Viega Technical Trainer Colton Henkowski and Social Media and PR Manager Rebecca Stamey, helped return access to clean, running water, by replacing all of the corroded galvanized pipes in homeowner, Sandy Thorton’s house, with new copper piping and 80 lbs of Viega ProPress fittings.

Since their introduction in North America in 1999, Viega press systems have earned a loyal following among plumbers and contractors who value their performance, efficiency and reliability. In recent years, this community has grown into a large following across Viega LLC’s social media accounts. In response, Viega LLC is recognizing some of its most enthusiastic Read more

Since their introduction in North America in 1999, Viega press systems have earned a loyal following among plumbers and contractors who value their performance, efficiency and reliability.

In recent years, this community has grown into a large following across Viega LLC’s social media accounts. In response, Viega LLC is recognizing some of its most enthusiastic and influential supporters through a new Press Masters Brand Ambassador program. The Press Masters are a group of highly skilled plumbing, HVAC, and general contractors who have built followings through their creative, and often entertaining, educational social media content.

In recent years, this community has grown into a large following across Viega LLC’s social media accounts. In response, Viega LLC is recognizing some of its most enthusiastic and influential supporters through a new Press Masters Brand Ambassador program. The Press Masters are a group of highly skilled plumbing, HVAC, and general contractors who have built followings through their creative, and often entertaining, educational social media content.

As Press Masters, they will use their social channels to educate people on the benefits of pressing with Viega fittings and share their trade expertise.

“The Press Master brand ambassador program is centered around building relationships with people who have shown great pride in their work using Viega fittings and who are passionate about being involved in the trade community,” said Rebecca Stamey, PR and Social Media Manager for Viega. “There is so much value in having the opportunity to partner with people who choose to use our products every day. We want to recoginize their endorsement for the brand and celebrate their accomplishments, all while also helping other realize the benefits of pressing.”

The current Press Masters are:

- Travis Abaire, @t.a.p.plumbingandheating, of Tap Plumbing & Heating in Bristol, Conn.

- Matt Fleming, @allstarplumbinginc, of All Star Plumbing & Heating in Manasquan, N.J.

- Terence Chan, @the__impetus, of Impetus Plumbing & Heating in Vancouver, B.C.

- Jonathan Cheever, @teamcheever, of Team Cheever Design Build in Park City, Utah

- Matt Benevides, @boston_plumbing_monstahs_, of Benevides Plumbing & Mechanical in New Bedford, Mass.

- Colton Henkowski, @viking_pipefitter, Technical Trainer for Viega in Broomfield, Colo.

To learn more about each Press Master and for those interested in applying to join the program visit viega.us/pressmasters.

In our continuing Industry Forecast series, we talk with Peter Orler, Strategy Director, Viega, on topics such as the short-term economy, supply chain issues, and lessons learned over the course of the pandemic. Here is our exclusive Q & A with Viega. MH: We’ve all experienced supply chain shortages recently in one form or another Read more

In our continuing Industry Forecast series, we talk with Peter Orler, Strategy Director, Viega, on topics such as the short-term economy, supply chain issues, and lessons learned over the course of the pandemic. Here is our exclusive Q & A with Viega.

Viega Assembly, Warehousing and Distribution—McPherson, Kan.

MH: We’ve all experienced supply chain shortages recently in one form or another. Do you project a turnaround soon or within the next 6-12 months for certain materials that relate to your specific company?

Orler: We’ve started to see some recovery in raw material availability early in 2022, but we expect to see shortages continue to pop up over the medium term. Labor availability is a huge driver of this—even where raw materials are available, it’s difficult to staff a complete workforce to fill production lines. The situation has really forced us and other manufacturers to adapt and become more flexible with our operations.

Viega Training Center, Broomfield, Colo.

MH: We are in the midst of some of the highest inflation rates since the early ’80s. Do you think that higher inflation becomes a “newer normal”? Explain.

Orler: Inflation may settle at higher rates than we’ve seen over the past two decades or so, but we don’t believe the current level of inflation represents a semi-permanent new normal. The economic situation over the past two years has been out of the ordinary for a number of reasons (e.g., COVID, supply chain disruptions, labor policies). In the past (e.g., late 70s) when we saw inflation reach these rates in the US, it has been for a period of 2-3 years before settling at a lower level. Monetary policy levers could bring it down faster as the Fed has signaled that quantitative easing will be phased out and interest rate increases are likely on the way.

MH: In general, how do you see the economy short-term? Give a few examples of how you draw that conclusion?

Orler: We focus mostly on commercial, multifamily, and institutional construction starts as our markets. 2021 saw a remarkable year-over-year increase (18% per Dodge) that brought us back to near 2019 levels. We’re seeing things even out to near normal (4% to 10% year-over-year increase in 2022 starts forecasted, depending on segment). Given our focus on pipes, valves, and fittings at Viega, we’re also paying particular attention to the impact of public investment funding on water infrastructure.

ProPress family

MH: Where are you seeing signs of positivity, if any?

Orler: We continue to see strong construction project volume, particularly focused in mid-size metropolitan areas. A few sectors stand out – healthcare starts have been impressive, warehousing and logistics facilities continue to grow as e-commerce demand remains high, and retail and office continue to work their way back from lows during the early part of the pandemic.

MH: How do you as manufacturers work with customers who are dealing with longer lead times and/or higher prices? Is it a matter of open lines of communication?

Orler: We’ve been as transparent as possible with our customers. One thing that we’ve found through this is that our customers care a lot more about reliability than speed. It’s been critical that, once we set an anticipated date and quantity, we deliver on that promise. Our customers have been understanding on both longer lead times and price increases as long as we clearly explain the drivers behind why it’s happening and deliver to what we promise.

MH: It seems that in today’s employment landscape, it’s hard to find good labor, whether it’s truck drivers, waiters at restaurants, etc. In our industry, how do we continue the fight to highlight the trades as a great career choice?

MH: It seems that in today’s employment landscape, it’s hard to find good labor, whether it’s truck drivers, waiters at restaurants, etc. In our industry, how do we continue the fight to highlight the trades as a great career choice?

Orler: It starts early—we need to ensure that students know that the trades are a strong option for their future. Our plumbers and mechanical contractors solve complex problems, deliver excellent customer service, and leave their mark on their communities. We partner closely with a network of trade schools to help promote the trades as a career and ensure these benefits are well known. We then work with plumbers and contractors throughout their careers—from apprentice to master—to meet their professional goals and become models to the next generation for what’s possible in the trades.

MH: In spite of COVID, people must move on. How has your company evolved—or continued to march forward—over the past two years, and talk about any new initiatives, expansions, etc.

Orler: COVID has helped us rethink how we engage our customers. A prime example of this is how we train customers to use our products – early in the pandemic, we designed the concept for ViegaWorks sessions which are remote engagements led by one of our very talented technical consultants. This started as a way to be there for our customers even when we couldn’t be on-site, but it has evolved into a tool that we’ll continue to use to deliver remote support even as we engage with more customers in-person.

We’ve also evolved our approach to customer outreach. In the past, we were able to rely on our boots-on-the-ground to reach every job site and contractor in their area. As job sites closed off and engagement moved remote, we found that marketing and inside sales could be a valuable approach to make sure we’re reaching every customer that would benefit from Viega press technology even with job sites closed to us. We’ve ramped up our promotions, including working with RIDGID and Milwaukee to offer press tools to contractors to introduce them to pressing.

As we’ve started coming back to in-person engagements, we’ve really tried to maximize our touchpoints with our customers. We were excited to see everyone at AHR and took the occasion to launch our new Viega valve lines live and in-person.