In our continuing Industry Forecast series, we talk with Peter Orler, Strategy Director, Viega, on topics such as the short-term economy, supply chain issues, and lessons learned over the course of the pandemic. Here is our exclusive Q & A with Viega. MH: We’ve all experienced supply chain shortages recently in one form or another Read more

Viega

In our continuing Industry Forecast series, we talk with Peter Orler, Strategy Director, Viega, on topics such as the short-term economy, supply chain issues, and lessons learned over the course of the pandemic. Here is our exclusive Q & A with Viega.

Viega Assembly, Warehousing and Distribution—McPherson, Kan.

MH: We’ve all experienced supply chain shortages recently in one form or another. Do you project a turnaround soon or within the next 6-12 months for certain materials that relate to your specific company?

Orler: We’ve started to see some recovery in raw material availability early in 2022, but we expect to see shortages continue to pop up over the medium term. Labor availability is a huge driver of this—even where raw materials are available, it’s difficult to staff a complete workforce to fill production lines. The situation has really forced us and other manufacturers to adapt and become more flexible with our operations.

Viega Training Center, Broomfield, Colo.

MH: We are in the midst of some of the highest inflation rates since the early ’80s. Do you think that higher inflation becomes a “newer normal”? Explain.

Orler: Inflation may settle at higher rates than we’ve seen over the past two decades or so, but we don’t believe the current level of inflation represents a semi-permanent new normal. The economic situation over the past two years has been out of the ordinary for a number of reasons (e.g., COVID, supply chain disruptions, labor policies). In the past (e.g., late 70s) when we saw inflation reach these rates in the US, it has been for a period of 2-3 years before settling at a lower level. Monetary policy levers could bring it down faster as the Fed has signaled that quantitative easing will be phased out and interest rate increases are likely on the way.

MH: In general, how do you see the economy short-term? Give a few examples of how you draw that conclusion?

Orler: We focus mostly on commercial, multifamily, and institutional construction starts as our markets. 2021 saw a remarkable year-over-year increase (18% per Dodge) that brought us back to near 2019 levels. We’re seeing things even out to near normal (4% to 10% year-over-year increase in 2022 starts forecasted, depending on segment). Given our focus on pipes, valves, and fittings at Viega, we’re also paying particular attention to the impact of public investment funding on water infrastructure.

ProPress family

MH: Where are you seeing signs of positivity, if any?

Orler: We continue to see strong construction project volume, particularly focused in mid-size metropolitan areas. A few sectors stand out – healthcare starts have been impressive, warehousing and logistics facilities continue to grow as e-commerce demand remains high, and retail and office continue to work their way back from lows during the early part of the pandemic.

MH: How do you as manufacturers work with customers who are dealing with longer lead times and/or higher prices? Is it a matter of open lines of communication?

Orler: We’ve been as transparent as possible with our customers. One thing that we’ve found through this is that our customers care a lot more about reliability than speed. It’s been critical that, once we set an anticipated date and quantity, we deliver on that promise. Our customers have been understanding on both longer lead times and price increases as long as we clearly explain the drivers behind why it’s happening and deliver to what we promise.

MH: It seems that in today’s employment landscape, it’s hard to find good labor, whether it’s truck drivers, waiters at restaurants, etc. In our industry, how do we continue the fight to highlight the trades as a great career choice?

MH: It seems that in today’s employment landscape, it’s hard to find good labor, whether it’s truck drivers, waiters at restaurants, etc. In our industry, how do we continue the fight to highlight the trades as a great career choice?

Orler: It starts early—we need to ensure that students know that the trades are a strong option for their future. Our plumbers and mechanical contractors solve complex problems, deliver excellent customer service, and leave their mark on their communities. We partner closely with a network of trade schools to help promote the trades as a career and ensure these benefits are well known. We then work with plumbers and contractors throughout their careers—from apprentice to master—to meet their professional goals and become models to the next generation for what’s possible in the trades.

MH: In spite of COVID, people must move on. How has your company evolved—or continued to march forward—over the past two years, and talk about any new initiatives, expansions, etc.

Orler: COVID has helped us rethink how we engage our customers. A prime example of this is how we train customers to use our products – early in the pandemic, we designed the concept for ViegaWorks sessions which are remote engagements led by one of our very talented technical consultants. This started as a way to be there for our customers even when we couldn’t be on-site, but it has evolved into a tool that we’ll continue to use to deliver remote support even as we engage with more customers in-person.

We’ve also evolved our approach to customer outreach. In the past, we were able to rely on our boots-on-the-ground to reach every job site and contractor in their area. As job sites closed off and engagement moved remote, we found that marketing and inside sales could be a valuable approach to make sure we’re reaching every customer that would benefit from Viega press technology even with job sites closed to us. We’ve ramped up our promotions, including working with RIDGID and Milwaukee to offer press tools to contractors to introduce them to pressing.

As we’ve started coming back to in-person engagements, we’ve really tried to maximize our touchpoints with our customers. We were excited to see everyone at AHR and took the occasion to launch our new Viega valve lines live and in-person.

Viega will sponsor pit crew in select races and have presence on the No. 47 Camaro ZL1 throughout the NASCAR Cup Series season. JTG Daugherty Racing has united with Viega, which is a a worldwide leader in pipe fitting installation technology for industrial, commercial, and residential projects. Viega is sponsoring the newly formed JTG Daugherty Read more

Viega will sponsor pit crew in select races and have presence on the

No. 47 Camaro ZL1 throughout the NASCAR Cup Series season.

JTG Daugherty Racing has united with Viega, which is a a worldwide leader in pipe fitting installation technology for industrial, commercial, and residential projects. Viega is sponsoring the newly formed JTG Daugherty Racing pit crew, and will have placement on Ricky Stenhouse Jr.‘s No. 47 Camaro ZL1 C-Post throughout the entire NASCAR Cup Series season.

“Viega supports professionals that make things happen, and we’re aligned to promote the high quality of their products,” Stenhouse Jr. said. “Pit crews are professionals with a special skill set, and they must have the right tools to do their job to work fast, efficiently and effectively just like the trades people working with Viega products. We have a fitting pit crew that Viega has partnered with this season. We’re looking forward to being successful on and off the track together, and communicating that Viega’s press technology is a safer secure alternative for connecting pipe.”

Viega’s saying is “Fast, Safe and Secure.” That key messaging will be showcased on the yellow and black Viega pit crew uniforms specially featured during 11 NASCAR Cup Series races this year when they service Stenhouse’s race car.

“Races are won and lost in the pits – it’s all about maximum efficiency and knowing the wheels are safely secured,” said Jared Mackrory, Viega Marketing

Director. “It’s the same challenge the professionals in our industry face as they install pipe fittings and hustle to get critical lines back up and running. We love that shared connection and are proud to support the professionals on the JTG Daugherty Racing pit crew.”

Viega’s pit crew uniform branding will include Las Vegas Motor Speedway (both races 3/6 & 10/16), Circuit of The Americas (3/27), Talladega Superspeedway (4/24), Dover Motor Speedway (5/1), Kansas Speedway (5/15), World Wide Technology Raceway (6/5), New Hampshire Motor Speedway (7/17), Pocono Raceway (7/24), Michigan Speedway (8/7), Watkins Glen International (8/21).

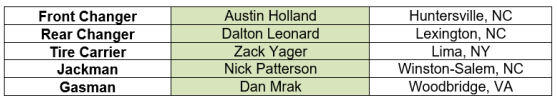

Viega is also pleased to announce the pit crew lineup for those races as follows:

For More information visit http://www.viega.us/ or contact the company at communications@viega.us.

Offerings now include new MegaPress®G valves for gas applications Viega LLC, the leader in pressing technology and systems, is now the single solution for press valves. Viega is introducing an entirely new line of MegaPress®G valves in sizes 1⁄2″ to 2″. These valves, like MegaPressG press fittings, are approved for use in gas and fuel Read more

Offerings now include new MegaPress®G valves for gas applications

Viega LLC, the leader in pressing technology and systems, is now the single solution for press valves.

Viega is introducing an entirely new line of MegaPress®G valves in sizes 1⁄2″ to 2″. These valves, like MegaPressG press fittings, are approved for use in gas and fuel oil applications. The valves are suitable for use with ASTM Schedule 5 to Schedule 40 carbon steel pipe.

Viega also is launching larger sizes of its MegaPress 3-piece ball valves, the first press ball valve of its kind in the 21⁄2″ to 4″ range.

In addition, ProPress® valves are now available in sizes 21⁄2″ to 4″ for use with copper and stainless CTS pipes.

The new valves are approved for more commercial, industrial and residential applications than any other system. All Viega valves are equipped with Smart Connect technology, which makes it easier to find unpressed connections.

Regardless of the application or product line, using Viega valves and fittings means no open flames, faster connections and greater labor savings, resulting in safer and more efficient projects that come in on time and on budget.

“The addition of our new valves means customers will no longer have to pair Viega fittings with valves from other manufacturers. Instead, they can install a complete Viega system with the confidence that valves and fittings are designed and engineered for each other and will deliver the highest quality in the industry,” said Luke Paulo, manager of product portfolio development.

To learn more about Viega valves, click here.

First technology to allow monitoring of every return circuit in a radiant system Viega LLC’s new Radiant Auto-Balancing System (RABS) delivers an unprecedented level of control and consistency in radiant heating systems. RABS gives users for the first time the ability to independently control each zone in a radiant heating system. Balancing valves are not Read more

First technology to allow monitoring of every return circuit in a radiant system

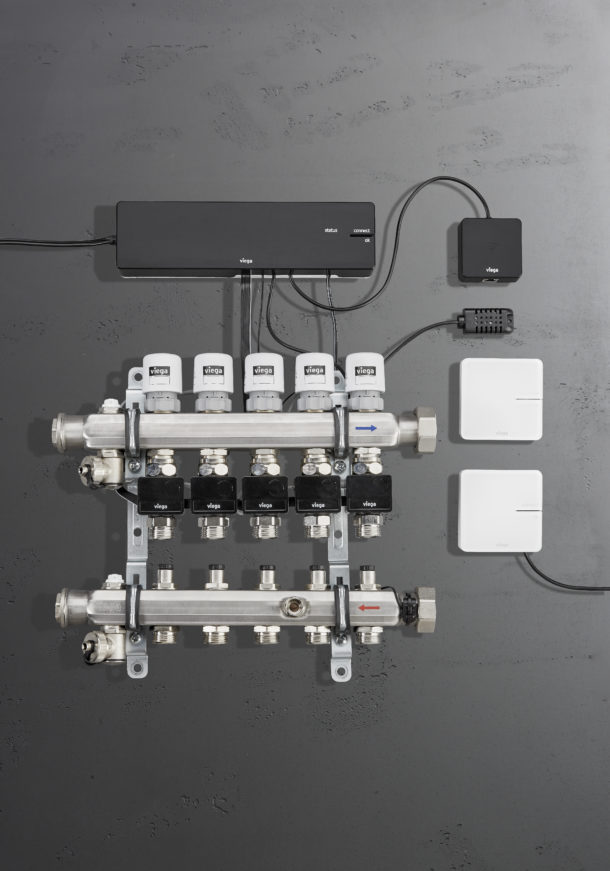

Viega LLC’s new Radiant Auto-Balancing System (RABS) delivers an unprecedented level of control and consistency in radiant heating systems.

RABS gives users for the first time the ability to independently control each zone in a radiant heating system. Balancing valves are not required and installers can commission as many as eight thermostats and 12 circuits per control unit. RABS achieves the desired temperature in each zone by analyzing the supply water temperature, each circuit’s return temperature and zone air temperatures where a wireless thermostat is used. The system offers four operation methods that complement each other.

“Achieving and maintaining consistent temperatures through multiple zones has been a challenge for radiant heating systems. RABS automates and digitizes the process, which helps installers and users alike,” said Adam Botts, Portfolio Manager.

RABS compensates for system inconsistencies and imperfections like:

- Different circuit lengths or tube sizes

- Varying installation clearances or tube depths/spacing

- Change of floor coverings

- Fluctuating supply temperatures, outdoor temperatures or external heat sources

In addition, a web-based app-enabled control lets users to manage the system from anywhere in the world. It allows remote control of power levels, thermostats and operation software. A local device can access the web app or it can be accessed remotely via the internet.

For more information about RABS, click here.

RLS LLC, manufacturer of the Rapid Locking System line of flame-free press-to-connect fittings for HVAC and refrigeration systems, announces that Milwaukee® Tool, in partnership with RLS, has introduced RLS-compatible jaws for use with its popular M18™ FORCE LOGIC™ Press Tools. Available in sizes from 1/4″ – 1-3/8″, these new RLS ACR Press Jaws will allow Read more

RLS LLC, manufacturer of the Rapid Locking System line of flame-free press-to-connect fittings for HVAC and refrigeration systems, announces that Milwaukee® Tool, in partnership with RLS, has introduced RLS-compatible jaws for use with its popular M18™ FORCE LOGIC™ Press Tools.

Available in sizes from 1/4″ – 1-3/8″, these new RLS ACR Press Jaws will allow M18 tool users to take advantage of the time-saving and safety benefits of flame-free RLS press connections for HVAC/R, without needing to invest in a new press tool. These are the industry’s first jaws approved to press RLS fittings using 32 kN (kilonewton) tools.

In addition, the new Milwaukee jaws are also compatible with a wide range of other 32 kN tools on the market, including those from manufacturers such as RIDGID, Klauke, Viega, Dewalt, NovoPress and Rothenberger. Contractors who already own any of these tools will only need to purchase the Milwaukee jaws to begin installing RLS fittings.

Milwaukee’s RLS-compatible jaws will be sold exclusively through Milwaukee distributors. Contact Milwaukee or visit milwaukeetool.com for details. For more information on RLS press fittings, and a complete RLS Tool & Jaw Compatibility Matrix, visit rapidlockingsystem.com.

About RLS Fittings

RLS press fittings connect in 10 seconds using a battery-powered tool and jaws, replacing the time-consuming process of manually brazing HVAC/R joints. The fittings result in faster, more consistent connections that reduce total installed costs, while also increasing jobsite safety by eliminating the use of an open flame. More than 10 million RLS fittings have been successfully installed since their introduction in 2015