At the Taco Comfort Solutions booth at this year’s AHR Expo, the company had a new twist—a virtual reality (VR) demo and a glimpse into the future of training. Mechanical Hub caught up with Dave Holdorf, Product & Application Instructor – East for Taco. Here is what Dave had to say: With the success of Read more

Industry Blogs

At the Taco Comfort Solutions booth at this year’s AHR Expo, the company had a new twist—a virtual reality (VR) demo and a glimpse into the future of training. Mechanical Hub caught up with Dave Holdorf, Product & Application Instructor – East for Taco. Here is what Dave had to say:

With the success of the Taco training department in the residential and commercial realms, as well as our webinar series of Taco Tuesday and Taco After Dark, what could be next? We have asked customers over the years what can we do to make the training experience better? The number one answer has always been more hands on. I would then ask, “how do we do that, you mean like installing a circulator and zone valves, joining pipe and flanges and tightening bolts … you mean like work on a jobsite you were at earlier in the week?” VR gives us that ability now—building a system, repairing the seals and bearing in a split case commercial pump, things like that.

Imagine maintenance on that split case pump is coming up and you have never, ever taken one apart much less seen one in the wild, but it‘s now your responsibility to do the repair in an effective and allowable timeframe. What are the proper steps … is there a YouTube video you can watch the night before … so much pressure to get the job done right.

Now imagine a call to us and we can meet you in the “mechanical room” with that very pump in front of us. We’re standing right next to each other virtually, but you’re in Walla Walla, Washington and we‘re in Cranston, R.I. rebuilding it with you—greatly improving your confidence level, and ready for the next day. With this capability, you know the sequence, you know the names of the parts, what to look for and what not to do.

In the end, attendees of the show were surprised, but not too much. I mean, the training department has been up to so much over the last decade bringing content online and in person that it wasn’t surprising that Taco would try to increase out reach even further.

Of course, we’re just scratching the surface of where we can go with this!

Anyone with a military background will recall the U.S. Government’s penchant for acronyms. MREs, BDUs, MRAPs, the list goes on. Unfortunately, this dynamic is also present when discussing the efficiency enhancing feature known as outdoor reset. ODT, SWT, LWT, etc. It’s enough to cause a BM in your BVDs! Well, U.S. Boiler Company has once Read more

Anyone with a military background will recall the U.S. Government’s penchant for acronyms. MREs, BDUs, MRAPs, the list goes on. Unfortunately, this dynamic is also present when discussing the efficiency enhancing feature known as outdoor reset. ODT, SWT, LWT, etc. It’s enough to cause a BM in your BVDs! Well, U.S. Boiler Company has once again developed a solution to make all this NBD.

First a few simple facts.

1. Flue gas will condense when temps are at or around 130° or less.

2. When vapor contained in flue gas condenses it releases a significant amount of heat.

3. Without question, optimal efficiency is achieved by heating a home using the lowest possible water temperature that will maintain the desired indoor target temperature, usually the thermostat set-point.

4. Using a Mod-Con, or high efficiency, gas boiler like the ALTA can take full advantage of the condensing action allowed by low water/flue temps.

Outdoor reset sensors do a wonderful thing. They enhance efficiency by matching water temperature to varying conditions. For example, one would want to maintain indoor design temp, normally 70°, during outdoor design temps (in CT normally 7-10 degrees.) Assume a 7° ODDT, and required SWT of 180. This means the boiler must deliver 180° supply water consistently at a 7° outdoor design temperature to maintain the desired indoor temp (IDT). This all simply means we need the hottest water when it’s coldest outside. Good so far?

As Paul Harvey used to say, “And now-The rest of the Story!” We now all understand (hopefully) what happens in our heating systems on the coldest day of the year. What about the rest of the time? Sure, that 180° water will heat the house just fine on a 50 degree day. But what about all the energy used to unnecessarily heat the water way past what would be required to keep the home comfortable? This is a net negative on many fronts, but most significant is the increased wear and tear on the heating unit.

So, your now asking “Tom, how low can my water temp be?” The answer will likely surprise you. Standard fin tube radiation works ok down to 130° water temps in most applications. Same with cast iron radiators. For the fin tube baseboard system in my house the minimum boiler water temp on my ALTAC-136 is 125 degrees. Hydro-air (hydronic coils added to or contained within hot air furnaces or air handlers) can often be run around 130° as well, depending on the occupant’s expectations. Remember, these SWT’s are typically targeted when the ODT is ~70°. We don’t need to transfer much heat to maintain indoor setpoints at these conditions. How does all this magic happen? Outdoor reset. Using a thermistor mounted outside, typically out of the sun on the north facing wall we monitor ODT and adjust SWT temp accordingly. So my personal curve used to be 180° SWT @ 7° ODT, and 125°SWT@70° ODT, but no more. My ALTA figures this out automatically without an outdoor reset sensor.

While outdoor reset simply monitors outdoor temperatures, rate-based reset works by looking at boiler run time, firing rate, and other parameters and adjusting accordingly. Here’s a few examples. Say it’s a beautiful spring day. Nice and sunny with a gentle breeze and 50° outdoor temperatures. The boiler run times are likely short, and the firing rate is likely low. The boiler knows from these conditions the heat loss from the house is minimal, and adjusts, incrementally dropping the boiler water temp until the minimum setpoint is reached, or our algorithm (the “secret sauce”) calculates that based on run time and firing rate the water temp will deliver enough heat to match the rate of heat loss and maintain indoor temp setpoints at the lowest possible SWT. As night rolls in and the temperature drops, average run times and firing rates increase, and once again, rate-based reset will adjust (increase) SWT’s to maintain indoor comfort and optimal efficiency. “Brilliant!” you say. I agree. But wait-there’s more!

Conventional ODR has limitations. Say the calculated water temp for a 45 degree day is 142°. It’s a moderately windy day. Consider two different houses, both 2,500 ft. The first has a well-sealed envelope, double pane windows, and effective insulation. The second has old single pane windows, minimal (or no) insulation, and is as drafty as old fence. The boiler doesn’t know what the indoor conditions are, just that it must target 142 degrees. That 142° SWT might be fine for the first, but far too low for the second. Now to be fair, all U.S. Boiler products with outdoor reset offer a “boost” feature that will automatically bump the temperature up every “X” (boost time value) minutes, default being 20. This means every 20 minutes with an uninterrupted call, the SWT will rise 10 degrees until the max setpoint is reached. The benefit of rate-based reset is we are always looking at indoor conditions and adjusting accordingly. Rate-based reset always uses the lowest possible water temp that will maintain the desired indoor temp, and then has the boost feature if an increase above the calculated target temp is required. Like a samurai sword: simple, elegant, and effective!

There are other benefits as well. Remember the test I mentioned? Here it is. What factors showcase the benefits of rate-based reset? See the answers below. Correct your test answers accordingly…

1. No sensor to install. Rate-based wins!

A) No sensor for landscape professionals to damage.

B) No sensor for contractor to install (or throw away!)

C) No wire required from boiler to sensor.

D) No worries about where the contractor will mount the sensor, if it will be impacted by the sun, or heat migration from the interior affecting the sensor calibration.

E) Enabled from the factory. No worries for homeowner regarding whether the contractor enabled ODR. The Alta boiler is set up for maximum comfort and efficiency right out of the box!

2. No Lemon Faces! Rate-based wins!

A) Always monitoring indoor temp. Onboard algorithms are constantly at work to meet heating demands while maintaining maximum efficiency. Tens of thousands of units installed with zero complaints about indoor temperature. When not writing informative and engaging articles such as this, I am a member of the renowned U.S. Boiler tech support team. I’ve honestly never received one complaint regarding rate-based reset. If you have, please contact me.

B) Not reliant on a technician with advanced, comprehensive knowledge of ODR curves. Works fine out of the box with no programming in most applications, and, where required, only minimal adjustments for almost all applications, including low temp radiant.

C) If the homeowner is made aware that during mild temperatures the radiators will not be the same temperature as the skin of the space shuttle during re-entry, and that these cooler temperatures mean more money in their pocket for candy/wine/shuffleboard, they will instead have smiles every time they touch the radiator. Or better yet, they will abandon the practice entirely…

3. Takes full advantage of condensing aspect of mod con boilers. Again, rate-based wins!

Regardless of ODT, rate-based reset always targets the lowest possible temp, thereby maximizing the potential for the boiler to run cool enough to operate in a range where flue gas condensation occurs.

I can almost feel grizzled old contractors firing up HP 386’s and waiting for the comforting squawk of their dial up modems connecting. I imagine most of the responses will begin with:

“Dear factory stooge/shill. Your article may fool the unwashed masses, but not me. My mom’s uncle’s grandmother has a hunting cabin with 1 radiator and 600 feet of ¾” pipe to connect the boiler to the house (it’s in the barn where we milk the squirrels). How does your new-fangled boiler work in my application? Hah!!! Gotcha!!!”

It will be this, or something substantially similar. There’s always at least one. For the rest of the world (and fortunately, most of the squirrels) these anomalies are rare. There is no magic solution for a poorly designed or installed system. But when a competent, capable, and progressive contractor is installing a new or replacement system, the advantage of rate-based reset over conventional sensor-based reset is clear. Reduced (or no!) programming required, no wires to pull, and no exposed exterior sensor susceptible to damage. Save time, money and aggravation. Go ahead and skip a step with ALTA.

For more information on the Alta boiler, visit our Alta Product Page.

GUEST BLOGGER: Tom Secondino is a Technical Sales Support Specialist for U.S. Boiler Company, a manufacturer of residential and commercial heating products, including condensing, non-condensing and electric boilers.

GUEST BLOGGER: Tom Secondino is a Technical Sales Support Specialist for U.S. Boiler Company, a manufacturer of residential and commercial heating products, including condensing, non-condensing and electric boilers.

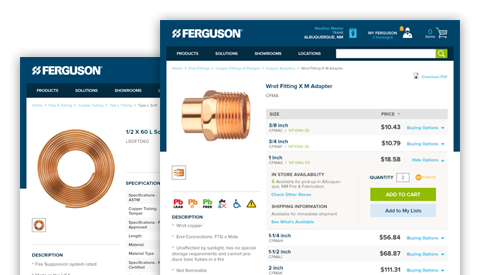

In today’s fast-paced world, leveraging the power of online resources is essential for the success of any plumbing contractor. Ferguson.com is that resource. As a busy service contractor, time is of the essence. When I plan out my busy week schedule, resource efficiencies are at a premium, and that includes stocking my truck adequately. Moreover Read more

In today’s fast-paced world, leveraging the power of online resources is essential for the success of any plumbing contractor. Ferguson.com is that resource.

As a busy service contractor, time is of the essence. When I plan out my busy week schedule, resource efficiencies are at a premium, and that includes stocking my truck adequately. Moreover, running a successful plumbing business requires access to quality products, reliable suppliers, and expert advice. In today’s digital age, having a robust online platform can significantly streamline your operations and contribute to your business’s growth.

In today’s post-COVID world, especially dealing with disruptive supply chain issues, it almost goes without saying; you can never have too much inventory on the truck or back at the shop. That’s why I rely on Ferguson.com, a comprehensive website that has plumbing contractor-specific resources available, all of which are literally just a click away. And that click provides real-time stock and pricing of more than 200,000 HVAC and plumbing products; I can see what’s in stock and my contract pricing.

My plumbing business relies on my wholesaler to carry a vast range of top-quality products from leading brands, and I trust Ferguson to provide those trusted, reliable, and durable solutions. Whether I’m looking for pipes, fittings, valves, fixtures, boiler parts or specialty items, I look to Ferguson.com.

Some really helpful features include “My Lists.” I am able to customize the order process with just a few clicks, instead of individually searching for the products I purchase regularly and organizing lists of the products I want. This ultimately has saved me time and has helped to streamline my ordering process. Ferguson.com even gives me the ability to share those lists I’ve created and keeps products I purchase under the “Bought Often” tab, which is automatically updated monthly.

The Quick Tools feature is a shortcut that makes it easy for trade professionals to quickly access other popular site features. It gives me the quick ability to order, reorder, find an order, or turn existing quotes into orders, all in one place. In some cases, I can even order online and have the order ready in an hour with Pro Pick-Up 1 Hour (at locations where Pro Pick-Up 1 Hour is available).

While traditional brick-and-mortar purchasing is still a viable wholesale solution, with Ferguson.com, I can gain access to a seamless and convenient online ordering system. This allows me to browse through products, check availability, compare prices, and place orders anytime, from anywhere. By simplifying the procurement process, Ferguson.com saves valuable time and effort, enabling me to focus on serving my customers better.

Furthermore, as a plumbing contractor, staying up to date with the latest industry trends and techniques is crucial. Ferguson.com offers a wealth of resources and expert advice to help me stay ahead of the curve. From informative articles and how-to guides to videos and product demonstrations, the website serves as a knowledge hub for plumbing professionals. Leveraging this wealth of information can enhance one’s expertise, expand a skill set, and ultimately elevate one’s business.

Furthermore, as a plumbing contractor, staying up to date with the latest industry trends and techniques is crucial. Ferguson.com offers a wealth of resources and expert advice to help me stay ahead of the curve. From informative articles and how-to guides to videos and product demonstrations, the website serves as a knowledge hub for plumbing professionals. Leveraging this wealth of information can enhance one’s expertise, expand a skill set, and ultimately elevate one’s business.

Sometimes I need to know what was on an order or the last time I bought a certain product. I’m able to find all of that online and end any confusion about my orders. If I need to see the status of an order, I can see it on my Ferguson Dashboard or Orders, and even get the proof of delivery. (Proof of delivery may not be available depending on how the order shipped or if it was signed for.)

Forward Thinking

Ferguson understands the importance of competitive pricing for plumbing contractors. By signing up for a Ferguson.com account, one can unlock access to exclusive contractor pricing on a wide range of products. This ensures that I can offer my customers competitive rates while maintaining healthy profit margins for my business. The savings one can achieve through Ferguson.com can significantly impact your bottom line and give you a competitive edge in the market.

It’s pretty simple, really. Creating an account on Ferguson.com provides plumbing contractors with a range of powerful tools to manage their business efficiently. By logging in, one can track his or her order history, access invoices, and manage one’s account settings, all in one centralized location. This streamlined account management feature eliminates the need for tedious paperwork and enables one to stay organized and in control.

What’s also cool about the site is that I can enroll for the free PRO Plus™ program. After I enrolled in this program, I now earn one point for every dollar I spent online. I can then redeem those points for cool prizes and earn Bonus Points faster by purchasing featured products. PRO Plus™ customers are also eligible for discounts with select businesses.

Ferguson.com boasts an extensive inventory of plumbing products, tools, and supplies, as well as expert advice and efficient account management, making it a one-stop solution for all of my business needs. By utilizing the features and capabilities of Ferguson.com, I can streamline my operations, relieve operational stress, and propel my business toward greater success. Sign up today and unlock a world of opportunities for your plumbing contracting business with Ferguson.com.

In today’s competitive market, it’s important to choose products that improve productivity and profitability. PEX isn’t a new pipe material, but more plumbers are choosing it as their preferred pipe type — and for good reason too. Explore the key reasons PEX is the best tubing to use for your next plumbing installation. 1. It’s Read more

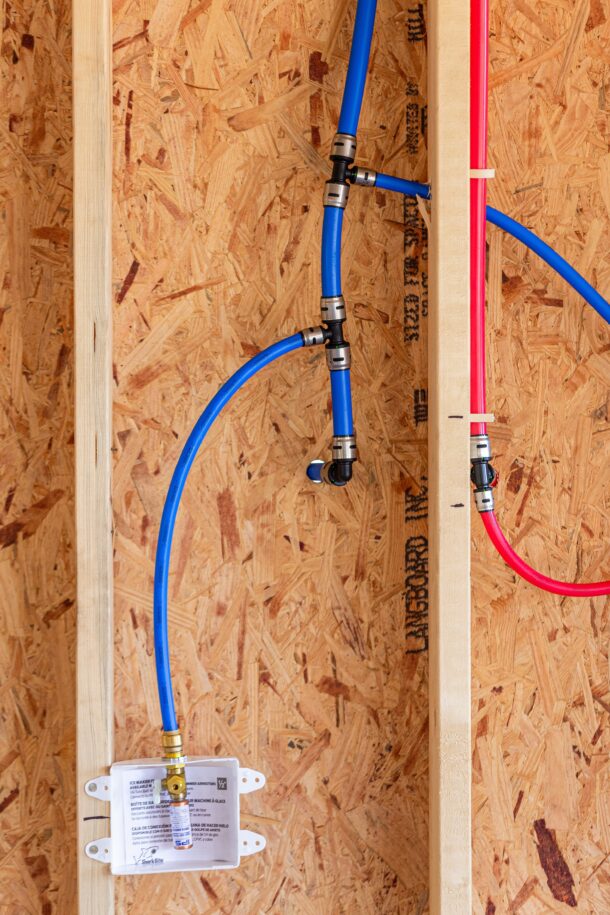

In today’s competitive market, it’s important to choose products that improve productivity and profitability. PEX isn’t a new pipe material, but more plumbers are choosing it as their preferred pipe type — and for good reason too. Explore the key reasons PEX is the best tubing to use for your next plumbing installation.

1. It’s more versatile

The initial cost of PEX is already budget-friendly, but its flexibility makes it even more so. The bendable tubing can maneuver around corners without the use of elbows or other additional fittings, making it easier for getting into places where rigid pipe isn’t easy to use.

Because its flexibility helps reduce the number of connections, PEX helps lower the cost of materials and minimizes potential leak points. Plus, you can install PEX pipe in longer runs with the use of coils that come in lengths up to 1,000 feet.

2. It’s quicker to install

One of PEX’s biggest draws is that it’s compatible with quick-installing plumbing solutions like SharkBite EvoPEX push-to-connect fittings that help you stay on schedule. In today’s labor market, that’s no small thing. Here’s why,

You need less labor. When you plumb PEX with push-to-connect fittings, you don’t need glue, solder, solvents or torches. These traditional techniques often require you to start and stop during installation, wait for glue or for water to dry before testing the plumbing system, or spend extra time cleaning up scrap material.

Bypassing these time-consuming processes means you can complete your installation with fewer people and without ever needing to pause your work. It also keeps potentially dangerous chemicals out of plumbing systems and removes the potential risk of fire from using torches on the job site.

You don’t need a specialized toolbox. Since they don’t require special tools, push-to-connect PEX systems give you more mobility compared to a two-hand system like crimp/clamp, while also significantly reducing the chance of installation errors and leaks. This in turn lessens the risk of water damage and mold.

As an advanced PEX push-to-connect plumbing system, SharkBite EvoPEX fittings even display a green visual indicator to assure you that a proper and permanent connection has been made. Plus, you can immediately test the plumbing system once the installation is done.

3. It performs better in the winter

The chemical composition of cross-linked polyethylene, the synthetic material PEX pipe is made from, allows the structure of the pipe to have more freeze resistance and elasticity under pressure. That means PEX will expand if water within the pipe freezes, and it’ll contract to its original shape when it thaws. This can help prevent other plumbing issues in the winter.

Additionally, the tubing has a host of other attractive features:

- It’s chlorine-resistant and resists scale buildup, which is common in copper pipe. Corrosion resistance facilitates more water pressure and better hot water delivery.

- You can find PEX that is tested to the highest level of chlorine resistance (100% chlorine at 140°F) and is certified to meet ASTM F876 oxidative-resistance requirements for continuous recirculation.

- PEX can withstand not only extreme low temperatures, but also extreme high temperatures too.

4. It’s sustainable

As the world focuses more on sustainable building practices, there’s a growing emphasis on reducing the long-term impact of building materials, including pipes. The good news is PEX addresses all three pillars of sustainability: environmental, economic and social impact.

Environmental. Polyethylene is a byproduct of oil or natural gas that’s already being extracted for other energy use, so PEX doesn’t require the extraction of natural resources just to make the tubing. It also doesn’t take a lot of energy to create PEX.

When the pipe is installed, it saves energy too. Polyethylene is a non-conductor and has insulation properties, which means PEX plumbing systems require less energy than copper systems to achieve a desired water temperature. And at the end of its life, the tubing can be ground up and used as a filler in composite lumber, playground equipment, traffic barriers and more.

Economic. Not only is PEX cheaper than other piping materials, but its bendability and compatibility with efficient plumbing solutions like push-to-connect fittings help save on parts and labor costs. Because it’s flexible and corrosion-resistant, it also has a long lifespan (about 50 years per PPI TR-3). This reduces costs, increases customer satisfaction and lessens waste.

Social. PEX and the innovative plumbing systems that it can be used with help address the industry’s labor shortage. It supports pros who have limited help in the field by making installations faster, safer and more reliable. Some other social benefits include:

- PEX is joined using mechanical fittings rather than soldering, which creates a potential fire hazard during installation.

- PEX systems are certified to NSF/ANSI/CAN 61, so they’re approved for potable water application.

- PEX is resistant to leaching, pitting and mineral buildup.

When picking a PEX manufacturer to work with, consider one that offers the highest-rated chlorine resistance and six-month UV resistance, such as SharkBite PEX-B. This tubing is also made in the U.S. — right in Cullman, Alabama — which creates and maintains jobs that boost the national economy.

80 Gallon Tanks, a Mainstay of Residential Construction, are Being Replaced With Smaller Units to Meet Energy Requirements Over the next decade or so, many veteran plumbers will recall the good old days as the ones where they installed 80-gallon electric water heaters. Once standard in many homebuilding projects, those tanks are products of bygone Read more

80 Gallon Tanks, a Mainstay of Residential Construction, are Being Replaced With Smaller Units to Meet Energy Requirements

Over the next decade or so, many veteran plumbers will recall the good old days as the ones where they installed 80-gallon electric water heaters. Once standard in many homebuilding projects, those tanks are products of bygone eras. Like Tyrannosaurus Rex, black and white televisions and 2-hour baseball games, their days have come and gone.

The impetus for the change occurred with the National Appliance Energy Conservation Act of 1987, an act of Congress that regulates energy consumption of specific household appliances. The death knell for the 80-gallon tanks sounded in 2015, impacting all conventional residential electric water heaters with a storage volume greater than 55-gallons. After significant postponement, NAECA III enforcement finally went into effect on January 1, 2022. While the installed 80-gallon electric tanks were allowed to remain in use, many of them have now reached the end of their useful life and need to be replaced.

Water heaters were not alone in the focus of NAECA: dishwashers, air conditioners, refrigerators and nearly every household appliance needed energy improvements, and manufacturers had to make swift changes to their products. The message was clear: reduce the energy demand for every home appliance and do it now.

Canada does not have similar laws – yet — but one project in Nova Scotia included the retrofit of an 80-gallon tank with a 55-gallon tank. The HTP Elevate water heater installed by Adams Heating is much lighter and takes up less space in the mechanical room.

“It’s the equivalent of a much larger tank, but it freed up a lot of space in the mechanical room and is a lot more efficient than a standard water heater,’’ said Brennan Ferguson of Bruce Sutherland Associates, who recommended the HTP Elevate for the installer.

The HTP Elevate includes 316L Stainless Steel, which provides greater corrosion resistance and includes an integrated mixing vale that protects against scalding. The Elevate comes with a limited lifetime warranty. (Photo courtesy of HTP)

Out With the Old

The retrofit was not uncommon. The century-old, 2,000 square foot home in Mahone Bay used the water heater for domestic hot water. The home’s heat comes from an oil furnace.

While there was no way to determine the precise age of the existing water heater, it had seen better days, to put it mildly. “It was an incredible failure of their onsite tank,’’ Ferguson said. “It was done.”

The homeowner contacted Adams Heating, which contacted Bruce Sutherland Associates. As the HTP representative in Eastern Canada, Brennan Ferguson felt the application called for the 55-gallon Elevate. “With the smaller footprint, and the difficulty in accessing the basement, we thought this might be a good opportunity,’’ Ferguson said.

The space savings in the mechanical room, improved efficiency, stainless steel tank and lifetime warranty of the HTP Elevate made the choice easy for the homeowner. “Going down the stairs with the smaller tank was easy,’’ Ferguson said. “The much harder part was removing the 80-gallon tank. It had been there for some time. It took 3 or 4 guys to manhandle that tank to remove it.”

Unique Features

Several features of the Elevate make it one of the most unique products on the market.

The corrosion-resistant 316L stainless steel tank is an industry rarity but is a top-of-the-line feature. 316L grade stainless steel provides greater corrosion resistance than other types of stainless steel, and is commonly used in marine applications, chemical and petrochemical industries, food processing and pharmaceutical equipment.

The other distinguishing feature is an integrated mixing valve that protects against scalding by safely and consistently mixing outlet water to the desired temperature of the homeowner. Combined with an adjustable thermostat, the Elevate allows for safe and consistent temperature at the faucet while amplifying the total amount of hot water available by safely turning the thermostat up to store water as high as 170°F. An ASSE 1017 anti-scald mixing valve is factory installed, so only inlet and outlet connections need to be established. This valve was chosen for its safety features and proven certification.

“When the water comes up through the mixing valve, it ensures safety on the other end,’’ Ferguson said. “We never want to deliver water more than 120 degrees to the tap. What this concept does is create a tank that delivers hot water reliably with a much smaller footprint and is much more effective than a standard electric water.”

The tank is also lightweight and much easier to handle than glass-lined water heaters and includes low watts density titanium elements that increase corrosion resistance and extend element life.

In a residential project in Canada, workers replaced an 80-gallon electric water heater with a 55-gallon tank from Ariston, the HTP Elevate, that is much smaller, lighter and takes up less space in the home’s mechanical room. (Photo courtesy of Brennan Ferguson)

Game-Changing Legislation

NAECA’s energy efficiency mandate changed the game for manufacturers, who needed to develop different products to comply with the legislation. Manufacturers responded, but now is a critical time in the industry. The lifespan of a typical electric water heater is 8-10 years, and many of the water heaters installed just before the original legislation are on their last legs.

Panic, however, does not have to set in for homeowners or contractors. While there are multiple options, the HTP Elevate is one of the newer products that gives contractors and homeowners peace of mind for the long haul and is easily installed with the added benefits of increased space in the mechanical room, use of premium materials (stainless steel tanks and titanium elements), and a limited lifetime warranty.

“The small footprint and stainless-steel tank make this a really good product,’’ Ferguson said. “It is something we’re going to recommend for a lot of residential retrofits and new installations.”

Thomas Renner writes on architecture, building, construction and other trade industry topics for publications throughout the United States.