For a boiler to operate properly, the liquid it contains must maintain the correct pH levels. If the pH level is not regularly tested and properly maintained, minerals can build up on the inside of the components. Or the water can turn acidic and attack the boiler’s metallic components and piping from the inside out Read more

Industry Blogs

For a boiler to operate properly, the liquid it contains must maintain the correct pH levels. If the pH level is not regularly tested and properly maintained, minerals can build up on the inside of the components. Or the water can turn acidic and attack the boiler’s metallic components and piping from the inside out, causing rust to form.

Scale or rust buildup reduces system performance over time. Enough buildup can essentially stop the operation of the system altogether.

Understanding pH levels in hydronic heating systems

Historically denoting “potential of hydrogen,” pH is the measure of how acidic or basic the water inside a hydronic heating system is. According to usgs.gov, the universal reading for pH goes from 0-14, with 7 being neutral. Less than 7 indicates acidity; greater than 7 indicates a base.

- Examples of items that have a pH of less than 7 are black coffee (pH=5), grapefruit juice, soda, or tomato juice (2.5-3.5), and lemon juice or vinegar (2).

- Examples of items that have a pH of greater than 7 would be seawater (8), baking soda (9.5), ammonia solution (10.5-11.5), and liquid drain cleaner (14).

pH is an important indicator of water that is changing chemically. Boiler systems need to have the perfect pH level balance. If the pH goes too high or too low, it can drastically impact a system.

The correct pH level will depend on the metallic composition of the heat exchanger. Some recommended pH levels range from 8 to 8.5. We recommend checking the boiler installation and operation manual to determine the acceptable pH range. Systems with a cast iron, stainless steel or copper exchanger are resilient and usually have a wide range of acceptable levels. Aluminum is more prone to corrosion and may require a specific pH.

Performing pH testing

Do a visual reading by opening the drain valve and bleeding off some liquid. If it appears clear, proceed with a pH test. As mentioned above, the correct pH level depends on the composition of the heat exchanger.

-

How to test pH levels

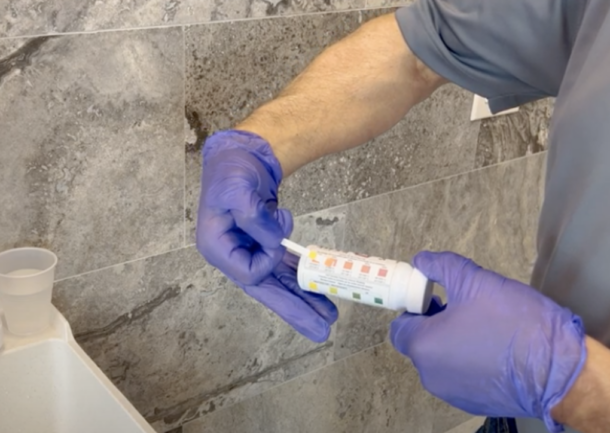

You can buy test strips that provide a color-coded readout. If you need a more precise reading for an aluminum system, use a digital pH meter.

Hercules Cryo-Tek Test Strips, available in packs of 6 to 10 color-coded and disposable test strips, can simultaneously check both the level of freeze protection (propylene glycol) and the level of corrosion protection in a system.

To conduct the test, drain some water from the boiler and then dip one of the pH test strips into the sample. Once a bit of color starts to pop up, compare the strip to the color chart to determine the pH level.

-

How often should you test pH levels?

These are closed systems, so there are usually no external signs of corrosion, making it difficult to spot an equipment leak — unless, of course, water is visibly running onto the floor. (If so, corrosive water inside the boiler is a likely cause.)

This general lack of immediate visibility is why it’s important to test hydronic systems annually. If your locale has hard water or there are conditions causing the water to be more acidic, testing should be done twice a year.

The lack of visibility is also why sampling the water for a test, as described above, is a must: It is the best way to tell if anything is wrong. If rust or sludge appears in your sample, you should test and replace the water.

-

What happens if a boiler’s pH is too high or too low?

If you find the pH levels too high, you’ll start to notice scale or limescale buildup in the boilers. Too much mineral buildup will restrict the system’s water flow. Essentially, the effectiveness of the boiler is lessened.

If the pH levels are too low, the water has turned acidic. This leads to rust and corrosion — a serious problem since boilers are typically made of copper, cast iron, and aluminum. As mentioned earlier, enough corrosion can stop system operation altogether.

-

How to balance out the pH

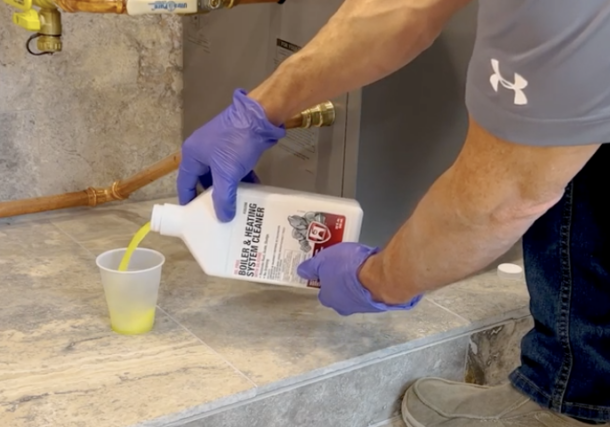

Maintenance managers or contractors can use a corrosion inhibitor to balance out the pH — a seamless fix. However, if the buildup or corrosion has been going on for several years, the system will probably not recover with this treatment. Instead, you’ll have to use a cleaner to flush the system to maximize boiler efficiency.

The Hercules® Boiler and Heating System Cleaner is formulated to clean and condition both steam and hot-water hydronic systems by removing rust, scale, and sludge. The cleaner can also free and lubricate zone valves and help stop priming and foaming with a special anti-foam agent. Ultimately, it is a liquid cleaner and corrosion-prevention treatment.

The Hercules® Sludgehammer System Restorer & Noise Reducer is another option for maintaining a boiler system. More aggressive than the system cleaner, it also cleans and reduces kettling (bubbling and banging), while restoring system efficiency. Maintenance managers or contractors can pair this product with a corrosion inhibitor for annual heating system-maintenance checks.

If the pH level is off:

- Drain about a gallon of liquid from the boiler and dispose of it.

- Fill a container with a quart of corrosion inhibitor, such as Hercules® Sludgehammer™ Universal Corrosion Inhibitor, and 3 quarts of fresh water. Pump it back into the system and allow it to circulate for about a half-an-hour.

- Test again. Usually, a single dose of inhibitor does the job, but if the reading is still too low, repeat the process

Watch the video below to learn how to remove sludge and corrosion in hydronic heating systems with Sludgehammer.

In conclusion, you must test the pH of boiler systems to maximize their efficiency, using products that can make monitoring pH levels simple and easy. If this testing uncovers damage to the system, there are also ways to alleviate and fix that damage.

But regardless of your boiler’s condition, Oatey products can offer a solution. For more information, go to Oatey.com for their heating chemicals and antifreeze products/resources.

Author’s biography: Sean Comerford is a Technical Applications Manager at Oatey Co. He is a third-generation tradesman with nearly 20 years of plumbing experience, including serving as the lead plumber for commercial/residential new-construction, service and fire protection jobs. He holds a State of Ohio Fire Protection License for Sprinkler and Standpipe.

Author’s biography: Sean Comerford is a Technical Applications Manager at Oatey Co. He is a third-generation tradesman with nearly 20 years of plumbing experience, including serving as the lead plumber for commercial/residential new-construction, service and fire protection jobs. He holds a State of Ohio Fire Protection License for Sprinkler and Standpipe.

Homeowners in the United States are becoming more inclined to update their residences with the latest smart home technology. Smart homes are the homes of the future and come fully equipped with a range of interconnected devices to offer benefits to the average homeowner. Smart voice assistants, smart kitchen appliances, smart home security systems, and Read more

Homeowners in the United States are becoming more inclined to update their residences with the latest smart home technology. Smart homes are the homes of the future and come fully equipped with a range of interconnected devices to offer benefits to the average homeowner.

Smart voice assistants, smart kitchen appliances, smart home security systems, and smart HVAC systems are examples of smart home technologies that homeowners are looking to adopt. It shouldn’t come as a surprise, considering how technology has developed over the years and how the consumer market is becoming more tech-savvy.

As American homes are evolving, how will the role of technicians change? Will technicians learn new skills or technologies to earn business from homeowners? Below is more information about smart home technology and how the role of technicians may change in an interconnected digital era.

Smart Homes Becoming More Commonplace

Statista estimates that the number of smart homes will increase and surpass the 350 million mark by 2023.

Many big tech companies, including Apple, Samsung, Google, and Amazon, are releasing new smart home technologies for customers. Smart TVs, sound systems, voice assistants, security systems, lighting systems, and thermostats are some examples of popular smart home technologies.

Homeowners reap a handful of benefits by using smart home tech. Convenience is likely the primary benefit – most smart home tech can be controlled by one device, usually a smartphone or tablet. These internet-enabled devices connect to hubs or applications for ease of use.

Impact of Smart Home Technology on the Role of Home Technicians

Because so many homeowners are equipping their homes with smart technology, this will likely change, if it hasn’t already, how home technicians do their jobs.

Typically, smart home technology does not have to be maintained or repaired as often as traditional home technology. For example, most systems will alert homeowners in advance of a breakdown, and some will even help homeowners troubleshoot issues.

However, because smart home technology has complex inner workings, technicians may have more difficulty completing repairs. Higher-end equipment often requires more skilled technicians to handle these types of repairs, or those with knowledge of proprietary systems.

What Technicians Need to Know

It will be crucial for technicians specializing in home maintenance or repairs to educate themselves and understand how basic smart home technology works. Service technicians will have to learn how these home devices connect and how each device functions to diagnose and repair issues.

Beyond working on smart technologies within customers’ homes during repairs, technicians may need to rely on these technologies for their own operations. For example, technicians might employ the use of electronic signatures to fuel their business and close deals more efficiently. Or, they may use wearables to capture and improve upon connected data like inventory and location information.

One major reason technicians will need to become more knowledgeable about smart home tech is that homeowner expectations are changing. A technician who has expanded their skillset to repair smart home tech will be in higher demand than those who do not.

As smart homes go mainstream, technicians capable of working on these complex smart home technologies will be well-positioned to offer their repair services, allowing their business to grow and generate more revenue.

Technicians: Keep Your Skills Relevant in the Age of Smart Home Technology

All technicians need to stay up-to-date with the latest technologies. Whether they specialize in HVAC, lighting, or plumbing, modern technicians should be aware of the adoption of smart home technologies to better prepare themselves for these repairs.

Guest Blogger: April Miller is a managing editor at ReHack.com who specializes in engineering and construction technology. You can find her work published on sites like Open Data Science and The Society of Women Engineers.

Guest Blogger: April Miller is a managing editor at ReHack.com who specializes in engineering and construction technology. You can find her work published on sites like Open Data Science and The Society of Women Engineers.

Speed and accuracy are the name of the game when it comes to a successful piping installation and a thriving business. Whether you’re installing potable plumbing or hydronic piping, the faster and more precise the job, the more time and money you potentially have to work on other projects. While there are hundreds of tips Read more

Speed and accuracy are the name of the game when it comes to a successful piping installation and a thriving business. Whether you’re installing potable plumbing or hydronic piping, the faster and more precise the job, the more time and money you potentially have to work on other projects.

While there are hundreds of tips and tricks out there to make your installs faster, easier, and more effective, I’m going to concentrate on the following three methods almost any plumbing or mechanical contractor can use to bring greater productivity to projects.

Flexible PEX pipe with bend supports

If you’ve never heard of PEX, it’s an acronym for crosslinked polyethylene. It’s a flexible, durable plastic piping product that provides numerous benefits over rigid CPVC or metallic systems, including faster installs, zero corrosion, and freeze-damage resistance.

Many residential contractors are already using PEX (considering it’s the most installed piping system for new-home construction over copper and CPVC combined). However, PEX is still a relative newcomer in the commercial industry.

The biggest benefit of PEX is its flexibility, which allows you to simply bend the pipe with each change in direction. With a tight bend radius of six times the pipe’s diameter, you can practically make 90-degree bends without the need for a fitting.

For times when you do have a tight bend that needs to stay in a particular place, PEX manufacturers offer bend supports. For those of you that prefer to watch rather than read, here’s a video that explains bend supports in detail.

These helpful products are available for ⅜”, ½”, ⅝”, ¾”, or 1″ PEX pipe. They hold the bend in place at the proper angle and take a fraction of the time compared to making a 90-degree elbow.

Most contractors agree that using flexible PEX with bend supports can eliminate most fittings in smaller-diameter pipe sizes 1″ and down, saving up to half the install time of a rigid piping system.

Expansion tools

When it comes time to make a connection with PEX pipe, the professionals’ choice is PEX expansion. Note that expansion connections are only designed for PEX-a pipe. If you’re using PEX-b or PEX-c pipe, you’ll need to use a different fitting type as PEX-b and PEX-c pipes aren’t made to expand like PEX-a pipe, and they will experience microcracking during expansion.

Expansion connections require one simple tool that expands the pipe and an expansion ring before inserting a fitting. As the pipe and ring shrink back down around the fitting, it creates a solid, strong seal that can withstand up to 1,000 pounds of radial force. It’s quick and easy to do and simple to learn, so it’s highly beneficial with the skilled-labor shortage that’s challenging the trades. Here’s a quick, 20-second video on how to make a connection.

Now, to make installs even faster, expansion tools have advanced to make connections even quicker. For up to 1″ connections, the Milwaukee® M12 FUEL™ ProPEX® Expander with RAPID SEAL™ Heads is the fastest tool yet — with up to 65% faster sealing times compared to previous models.

For larger-diameter pipe connections, the new Milwaukee M18 FUEL™ ProPEX Expander with ONE-KEY™ is taking commercial installs to a new level by offering 3X faster 2″ connections. To watch how much faster, check out this video from Milwaukee Tool.

Prefab

Finally, let’s talk about prefabrication. This is becoming a big trend for national residential builders or large commercial projects that have a lot of repeatability on the project. By prefabbing certain sections of a project, it can shave days, weeks, or even months off a timeline, depending on how big the project.

Prefabricating piping assemblies in a controlled factory environment not only adds more efficiencies, it also provides an additional benefit of greater accuracy. By doing a job repeatedly, it hones the skill and gives installers greater confidence in their work.

Plus, having rows and rows of prefabbed piping assemblies in a shop environment makes it a lot easier to perform quality checks. Instead of walking for miles on a job site, a supervisor can save significant time simply walking a shop floor.

And here’s another area where flexible, durable PEX provides additional benefits. Transporting prefabbed PEX piping assemblies is much easier than transporting rigid assemblies that can crack or break. Because PEX is super flexible, it can withstand the rigors of being transported to a job site without worry.

So, there you have it…just a few ideas to keep in mind the next time you have a project with a tight deadline, and you’re squeezed on time and skilled labor. Every little bit helps when it comes to adding productivity to projects. If you have other ideas, I’d love to hear them. Feel free to email me at kim.bliss@uponor.com.

Kim Bliss is the technical and marketing content manager at Uponor. She can be reached at kim.bliss@uponor.com.

Kim Bliss is the technical and marketing content manager at Uponor. She can be reached at kim.bliss@uponor.com.

What is corrosion? We’ve all seen it and talked about it at some point, right? So, how well do we really understand it? It is important to understand that corrosion is a natural process, and it will occur in every system where any type of metal is present. From pipes and fittings to major components Read more

What is corrosion?

We’ve all seen it and talked about it at some point, right? So, how well do we really understand it?

It is important to understand that corrosion is a natural process, and it will occur in every system where any type of metal is present. From pipes and fittings to major components, corrosion is part of a natural process for any metal that has been refined and then formed into a manufactured component.

Once formed, the clock begins! These metal parts and pieces are actively working on returning to their natural form, into a more stable state such as an oxide. This is how we end up with black iron oxide, or magnetite as one result of this natural process.

How does this apply to hydronic systems?

While there are many causes and contributing factors to corrosion, the biggest concern for any hydronic system is the risk of blockage. Blockages can not only dramatically reduce the efficiency of your system, they can prematurely shorten the functional life of your major components.

Knowledge is power, and a little extra effort now can yield years of higher efficiency and longer life for your systems’ components. Another important concept to realize, particularly in hydronic heating systems, is that heat accelerates the process of corrosion. That’s right, a hydronic heating system by its very nature is a catalyst for corrosion!

Black iron oxide or magnetite is often recognized as black water, black sludge, mud, dirt, or metal flakes in the water.

Counteract Corrosion

We can prevent corrosion from occurring in a new system, and we can even slow down the process in an existing system via three simple steps: Test, Clean, Protect.

Test

Testing is a vital step in understanding the quality of the water in the system. A test identifies whether corrosion is occurring, and also advises on what needs to be done to recover the system water and components. Read more about our water testing tools here.

Clean

Any system with corrosion occurring will need a clean. Our MC3+ cleaner is a neutral based cleaner, designed to lift and dislodge scale and iron oxide that has built up on system components and pipework. This cleaner also contains a small amount of inhibitor that will protect the components as it’s cleaning. For more information on our MC3+ cleaner, click here.

Flushing the system is also required after cleaning, and this can be done using our MagnaCleanse flushing machine. The unit works as a by-pass, allowing the system to be cleaned with no system shutdown; this also means that the system water remains hot, providing a better clean. Find out more about this money-making machine here.

Protect

Unfortunately the process of corrosion never stops, which is why any hydronic system will need the long-lasting, continuous protection of a magnetic filer. Our MagnaClean filters collect the iron oxide that has been loosened by the cleaner, and will continuously collect any future iron oxide to provide on-going protection for the system and its components. MagnaClean filters are available in a wide range of residential and commercial sizes for any type of hydronic system, whether it be a boiler, chilled water, or steam system.

Inhibitors are also vital in ensuring the on-going protection of the system. Our MC1+ protector provides a protective coating on all system components to prevent future corrosion from building up, and also contain pH buffering agents to neutralize pH levels which will prevent future acidic or alkaline corrosion. More information about our MC1+ protector can be found here.

Counteract corrosion: TEST. CLEAN. PROTECT.

Warning: Chemicals should not be used in steam systems due to higher temperatures. Magnetic filters can be used for steam system protection. For more information, please visit https://www.adey.com/us/corrosion

BIM, which stands for “building information modeling” is becoming the fastest-growing innovation for managing commercial construction projects. From adding greater efficiencies and productivity to reducing product waste and employee resources waste, BIM is providing benefits for everyone in the design and construction chain — from engineers to project managers to installing contractors. BIM defined So Read more

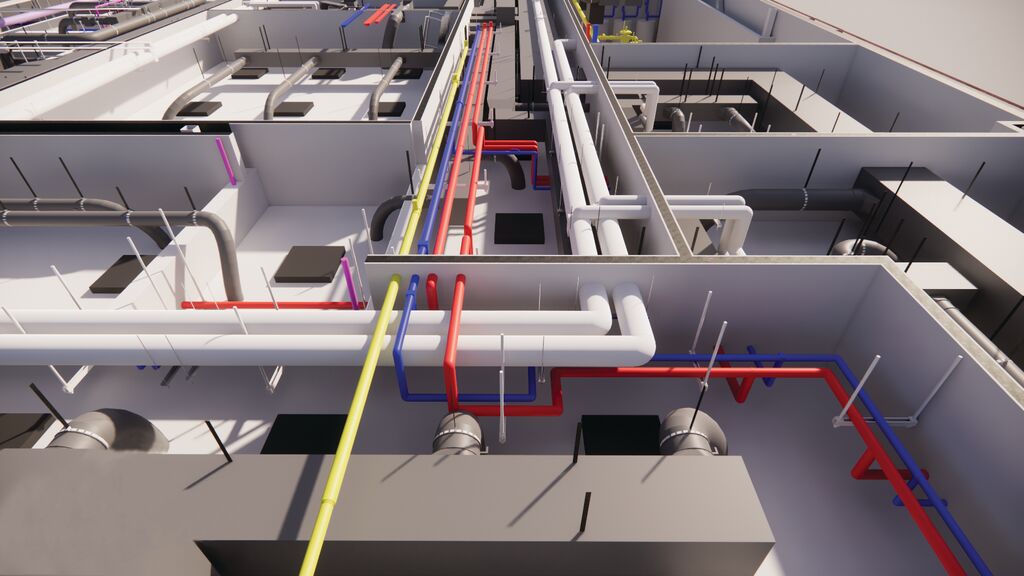

BIM, which stands for “building information modeling” is becoming the fastest-growing innovation for managing commercial construction projects. From adding greater efficiencies and productivity to reducing product waste and employee resources waste, BIM is providing benefits for everyone in the design and construction chain — from engineers to project managers to installing contractors.

BIM defined

So what exactly is BIM? Simply put, BIM is a collaborative process. It incorporates teams, technologies, and tools to generate and manage digital assets that represent the physical space of a building to be renovated or newly constructed from the ground up.

Engineers are able to design a building holistically with improved visualization based on higher-quality 3D models generated from the BIM process. Contractors are then able to gain greater efficiencies and productivity during the installation process because issues and conflicts have already been addressed before construction even begins.

BIM Services departments

With this growing trend, companies are seeing the bottom-line benefits of BIM and are now creating their own BIM Services departments. These teams are typically led by a vice president or director and include project managers and business development managers that work one-on-one with clients to provide everything from modeling and coordination, laser scanning, BIM coordination management, BIM training, onsite collaboration, template development, and workflow optimization.

For modeling and coordination, a BIM Services department can provide hanger layouts and structural supports, in addition to spooling and fabrication detailing along with shop, install, and as-built drawings. Some BIM Services teams can even offer laser scanning services, which can include everything from scanning of existing buildings for renovation, scanning completed projects for documentation, and scan-to-BIM services.

How BIM supports installing contractors

By utilizing BIM or partnering with a BIM Services provider, it can increase efficiencies in workflows to help identify issues early on in a project to maximize productivity and minimize waste.

For example, a company can leverage 3D models to validate designs from the onset of design to improve overall project execution and collaboration. This leads to reduced design errors, resulting in higher design accuracy, which saves time and money by reducing rework and change orders.

Accurate and well-coordinated designs also lead to improved job costing through more accurate quantities and estimates, resulting in reduced job-site waste.

Contractors can also gain more precise site logistics by leveraging accurate models to create model-based schedules or sequences. Additionally, look-ahead plans, work-in-progress models, materials planning, equipment and rigging locations, site traffic patterns and controls, and even location-based schedules can all be derived from well-coordinated 3D models to optimize daily job-site activities.

Choosing a BIM Services provider

What is true with real estate is also true with a BIM Services provider: it’s all about location. Some BIM Services companies are located overseas, so the opportunity to have live interaction or even in-person collaboration is very challenging or impossible. Be sure to go with a BIM Services provider located in your region, or at least in your country, so collaboration can happen in real time.

It is also important that the BIM Services team has knowledgeable experience with the codes and standards in your jurisdiction as well as the construction practices in your area. Certain commercial projects, like hospitals, may have specific construction methods that must be adhered to for code. Make sure the BIM Services team you’re partnering with knows these important details.

Additionally, it’s beneficial to work with a team that has affiliations with industry organizations such as ASPE, ASHRAE, and MCAA, to ensure they’re up-to-date on the most current trends and information in the industry.

Finally, it’s important to consider cost when it comes to choosing a BIM Services provider. It’s true what they say: you get what you pay for. So, when researching providers, consider the experience of the team and the support they can provide when weighing how much you want to pay for these services.

Because BIM is a relatively new concept to the construction industry, experience is in short supply. That said, look to these providers for training for your staff. It’s a great way to add value to your company and provide future projects with greater efficiencies and productivity.

Kim Bliss is the technical and marketing content manager at Uponor. She can be reached at kim.bliss@uponor.com.

Kim Bliss is the technical and marketing content manager at Uponor. She can be reached at kim.bliss@uponor.com.