https://youtu.be/-J5kLQiusWQ Mechanical Hub’s Eric Aune has exclusive interview with Greenlee Textron’s President and CEO, Jason Butchko at the 2018 AHR Expo. They discuss tools in marketplace and focus of Greenlee to create products for the mechanical tradesperson Read more

ProStaff

https://youtu.be/-J5kLQiusWQ

Mechanical Hub’s Eric Aune has exclusive interview with Greenlee Textron’s President and CEO, Jason Butchko at the 2018 AHR Expo. They discuss tools in marketplace and focus of Greenlee to create products for the mechanical tradesperson.

There are three things I want to highlight in this video, not all are totally flattering so please take a look: 1. The 2nd generation M12 Fuel Impact is even better than the first and that’s actually incredible because anyone who’s owned the 1st gen knows it’s a very nice tool. 2. The Smith HE2 Read more

There are three things I want to highlight in this video, not all are totally flattering so please take a look:

1. The 2nd generation M12 Fuel Impact is even better than the first and that’s actually incredible because anyone who’s owned the 1st gen knows it’s a very nice tool.

2. The Smith HE2 copper fintube baseboard is fabulous. The performance is crazy awesome and makes it the best bb on the market for mod/con & electric boilers, without a doubt. Don’t argue with me on this, I’ve tried them all and I’ve installed miles of bb. This is a fact, it’s science.

3. The Milwaukee Tool dipped gloves (I’m wearing the cut level 1 pair here) are nice but too stiff in the cold for my liking. Also, they’re supposed to have “SMARTSWIPE” index fingers but I can tell you first hand they don’t work on my iPhone 7+ at all. I’m told that this may be due to my screen protector or the angle of my finger. They did however protect my hands against the 750 million cuts I would’ve received from the razor sharp aluminum fins on the bb. They’re priced right in my opinion and I’d have no problem buying more pairs because they fit well and offer the protection I am looking for.

Hope this helps,

Eric Aune

Aune Plumbing, LLC

Mechanical Hub ProStaff

I recently installed my first Lochinvar Noble combi-boiler, it was a replacement upgrade from a failed dual purpose tank heater supplying heat to both garage and basement radiant floors. This model was the 199K Btu running on natural gas, vented in 3″ (factory outlet size on boiler) with a rating of 95% AFUE. Lochinvar specs Read more

I recently installed my first Lochinvar Noble combi-boiler, it was a replacement upgrade from a failed dual purpose tank heater supplying heat to both garage and basement radiant floors.

This model was the 199K Btu running on natural gas, vented in 3″ (factory outlet size on boiler) with a rating of 95% AFUE. Lochinvar specs the domestic delivery to be 4.8 gallons per minute (77F rise, NKC199 model only) and that was the deciding factor in selecting this model. With a 10:1 turndown ratio the heating capacity of this unit is right-sized for the load even though its capable of much more. Domestic production takes president in this situation.

The Noble boiler is equipped with Lochinvar’s SMART CONTROL and features an intuitive setup wizard to guide contractors through programming parameters quickly and easily. The backlit, user-friendly LCD display provides diagnostic information and system status in plain English, not codes.

Of course this unit is my first of the model line and has only been in operation for about a week as of this posting so I have no long term experience with performance and reliability but based on my experience with the Knight and Cadet models I have relatively high expectations for this one to serve my client well.

Here’s a link to some video I took while installing the system (Click the arrows to advance thru the video clips):

https://www.instagram.com/p/BbPTM8QBHu9/?utm_source=ig_share_sheet&igshid=uf9c5lrmm0y4

Many pro tradesmen and women work with grinders daily, with the advancement in battery tool technology cordless grinders have become a favorite tool for many trades because of the speed and versatility they offer. Small grinders fit into hard to reach areas and offer the ability to cut materials at speeds other tools cannot match Read more

Many pro tradesmen and women work with grinders daily, with the advancement in battery tool technology cordless grinders have become a favorite tool for many trades because of the speed and versatility they offer. Small grinders fit into hard to reach areas and offer the ability to cut materials at speeds other tools cannot match.

Many pro tradesmen and women work with grinders daily, with the advancement in battery tool technology cordless grinders have become a favorite tool for many trades because of the speed and versatility they offer. Small grinders fit into hard to reach areas and offer the ability to cut materials at speeds other tools cannot match.

Simply put, grinders are such a useful tool and are found on the trucks of HVAC techs, plumbers and electricians alike.

For years I have used my grinder with a thin cutoff wheel for cutting into cast iron plumbing stacks and lateral drains and until just a couple months ago the wheel of choice has been a bonded abrasive disc. I have completely replaced all abrasive discs with the new Diablo Diamond Cutoff Wheels for many reasons, chief among them being safety.

We have all heard of bonded wheels shattering under load and causing the user physical harm. There’s no shortage of pictures available on the Internet of bits and pieces of abrasive wheels embedded in various body parts [go ahead and Google it but I don’t recommend it for anyone with an aversion to blood or graphic bodily injury, do so at your own risk] Diablo’s answer to safety concerns regarding metal cutoff wheels is the new solid metal cutoff discs that will not shatter or break when dropped or banged around a little on the site or in the truck.

These wheels will outperform abrasive cutoff wheels in life expectancy hands-down. Its important to know straight away that the continuous-edge diamond grit metal cutting discs are not all-day production cutoff wheels but for the tradesperson who uses a grinder for cutting occasionally throughout the day or week, this is a solid and safe alternative to a bonded wheel.

The speed in which bonded wheels remove materials is always going to be hard to beat. This cutoff disc will not match or beat an abrasive wheel but it will last considerably longer and remain the same diameter throughout its useful life. That’s not ever going to be true for a bonded wheel; yet another advantage Diablo’s disc offers the user.

For the last couple months we have actually began to use our grinders more because of these discs. Knowing I don’t have to search for a new cutoff wheel for nearly every tie-in out of concern that the disc already loaded on the grinder may have been compromised in handling or storage. Instead I have confidence that the solid metal disc will not shatter when I plunge thru the sidewall of the 4” no-hub in front of me.

Cutting pipe is not the only use we have for these wheels though, they’re often used to cut sheet metal, threaded rod, steel pipe and even during demo work the occasional slew of copper tubing nightmare.

One criticism I have for the design of the diamond grit cutoff wheels would be that they could benefit from an increase in thickness. They’re very thin and can become warped when put under high loads in heavy cuts. That’s an obvious problem requiring immediate replacement for not only performance but safety as well. Increasing the thickness of the disc and adding a segmented rim might best realize this. I have had multiple conversations with the design engineers and product managers about these wheels and have little doubt that this is just the first of an expanding diamond cutoff wheel product line.

So far I have only found these available at The Home Depot. Sizes ranging from 4.5”, 5”, 6” & 7” and costs starting at $14.97 in my local market (MN).

Overall I would definitely recommend exploring the new diamond grit cutoff wheels from Diablo. If you’re using a grinder for occasional metal cutting then you owe it to yourself to increase the safety aspect of this task.

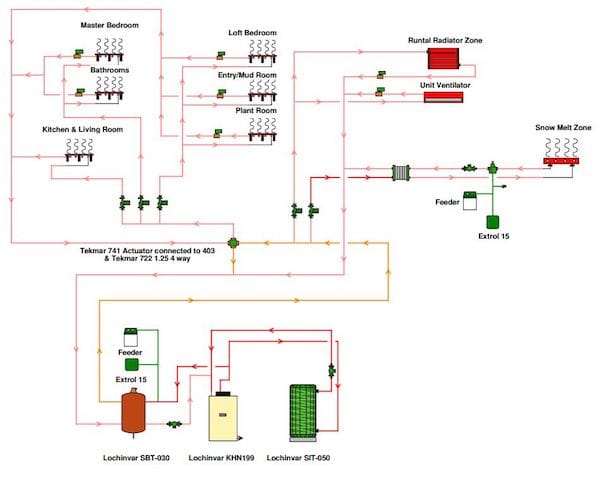

Complex hydronic systems are so 2008, at least according to Mechanical-Hub ProStaffer Andy Mickelson, who owns Mickelson Plumbing and Heating in Missoula, Mont. His three-man shop does plenty of high-end residential work, and even here—no—especially here, their recipe for success, serviceability and efficiency includes a heavy dose of “keep it simple.” On a custom home Read more

Complex hydronic systems are so 2008, at least according to Mechanical-Hub ProStaffer Andy Mickelson, who owns Mickelson Plumbing and Heating in Missoula, Mont. His three-man shop does plenty of high-end residential work, and even here—no—especially here, their recipe for success, serviceability and efficiency includes a heavy dose of “keep it simple.”

On a custom home, where some contractors may be tempted to stack the material list high and deep, Andy does the opposite. He takes a step back from the blueprints and figures out how to use the fewest components needed without any compromise. Numerous zones, DHW production, multiple supply temperatures and snowmelt loops can and are all handled without making things more complicated.

“There are a number of things you can do to keep systems simple,” said Mickelson. “I make sure to avoid ‘inadvertent’ redundancy: that is, two products that accomplish the same task.

Proper sizing of radiation, pipe, pumps and boilers accurately is obviously important, too. Picking a control system that accomplishes what you need and nothing more is helpful.

Another thing we began doing a few years ago—and have noticed an improvement since – is sizing and grouping our zones to the capacity of a specific pump, instead for creating a zone with no real parameters, and trying to find a pump that fits the zone or zone group.”

Like a round peg in a round hole, selecting your circulator first can save a lot of trouble, as well as the issues that come with over- or under-pumping a system.

Starting in late October of last year, Mickelson was hired for a job that would test his ability to “keep it simple.”

Mickelson’s work included installation of a mod-con boiler, seven zones of in-floor radiant, a hydronic unit ventilator, high-temp baseboard and 400 sq.-ft. of snowmelt.

Just out of town, the customer had purchased a nice lot with an older, 800-sq.-ft. home. The house was leveled and the basement foundation was re-used. The plan was to build a new 5,000-sq.-ft., two-story home on top of and around the original foundation.

Pick the pump first

“Like we do on all our jobs, I interviewed the homeowner long before we started the work, in order to really understand what they wanted,” said Mickelson. “Comfort was paramount, and budget not as much. So a thin concrete slab covers all radiant tubing, which is set at nine-inch centers.”

Before Mickelson started his loop layouts, he chose the Taco VT2218 variable speed circulator to serve all of the zones, with a total of six pumps. Additionally, Taco 007e single-speed ECM circulators are used on the 200 MBH fire-tube boiler and the indirect water heater.

“I like a Delta-T pump on a job like this, but another reason I used the VT2218 is for its broad pump curve, and we made use of it,” explained Mickelson. “It’s also very easy to program. Each radiant pump serves a group of zones. The zones are paired up according to the pump’s capacity, in terms of both head loss and flow rate. That way there aren’t any extra, underutilized circulators.”

Once the pump has been selected and the heat loss has been completed, the zones can be designed to fit the home. A common misconception about radiant circuits is that they must be as close to 300 feet long as possible, this just isn’t true. By dropping the length of each circuit, the head loss can be comfortably managed. The downfall to this is that the zone may require more circuits, but honestly the difference between five circuits and seven is minimal. It’s the same amount of tubing, no real noticeable increase in labor, just a larger manifold and a manageable head loss.

Low temp

Through zone valves, each pump supplies the appropriate amount of water and heat to a Watts Radiant stainless steel manifold, located remotely. Half-inch Watts RadiantPERT tubing was laid out before the gypcrete was poured.

“We chose the PERT instead of PEX because the radiant work was done throughout the winter. With spells of sub-zero weather, the increased flexibility of PERT was a huge benefit, especially considering our tight tube spacing.”

Because of the hydronic radiators, unit ventilator and snowmelt, the boiler maintains the buffer tank at 140°F at an outdoor design condition of -15°F. To make low temp water for the radiant zones, a Watts 4-way mixing valve with a tekmar 741 actuating motor was used. The 741 communicates with a tekmar 402 House Control in order to supply the exact radiant temperature need based on the outdoor temperature.

“The mixing valve sets the final delivery temp to all the low-temp zones,” said Mickleson. “It’s one of three elements at play here that really allow us to provide the exact temperature and flow rate to the radiant zones, so we’re really capitalizing on the primary/secondary piping, and squeezing every last ounce of comfort and efficiency out of the system. The other two elements are the outdoor reset on the higher temp boiler zones, and the variable-speed, Delta-T pumps. They all work hand in hand.”

The home has several areas with structural elements which made installing some of the tubing a challenging. Because of this, Mickelson had no choice but to run PEX supply and return piping through exterior walls. As a guard against the challenge of Montana winters, he wanted to run a glycol solution in the system. He installed a Neutra-Safe system feeder, which is an all-in-one reservoir, pump and control.

The home has several areas with structural elements which made installing some of the tubing a challenging. Because of this, Mickelson had no choice but to run PEX supply and return piping through exterior walls. As a guard against the challenge of Montana winters, he wanted to run a glycol solution in the system. He installed a Neutra-Safe system feeder, which is an all-in-one reservoir, pump and control.

High temp

The fourth and fifth VT2218 circulators serve the home’s three high-temp zones directly out of the buffer tank. In the basement, where the existing, uninsulated slab is still in place, Runtal baseboard was used in lieu of radiant tubing. Mickelson had considered ceiling radiant, but there wasn’t enough height to allow it. The circulator used for the baseboard zone also supplies water to the 12,000 BTU Smith Environmental unit ventilator in the garage attic.

The last variable-speed circulator serves as the snow melt system pump on the loop side of the brazed-plate heat exchanger. Mickelson uses a tekmar 654 Snowmelt Control to manage automatic operation and maintain a 25°F Delta-T across the 400 square-foot zone. This control features a snow and ice sensor that’s set in concrete when poured. The snowmelt loops also utilize a second Neutra-Safe System Feeder.

“Because of the components used and a thoughtful design, we’re covering five different loads with one boiler while installing it in a relatively tight space, all without being overly complicated,” said Mickelson.

Each pump supplies the appropriate amount of water and heat to a Watts Radiant stainless steel manifold.

“In the case of an emergency, I only have to deal with a single control system or one replacement pump,” he added. And with all that said, I can’t think of a quieter, more comfortable, or higher efficiency heating system.”

Mickelson is now going over a punch list, and looking forward to the feedback from the customer. He’s expecting rave reviews about the comfort level, and complete satisfaction when the owner receives their first propane bill.