Epoch Senior Living Inc. operates 10 Bridges by Epoch Memory Care Assisted Living Facilities throughout New England. Over the years, management has sought to provide the highest level of resident comfort and environmental sustainability. Partnering with architects, designers and mechanical system installers that understand these priorities has lead the company to continuous growth. At nearly Read more

Pumps

Epoch Senior Living Inc. operates 10 Bridges by Epoch Memory Care Assisted Living Facilities throughout New England. Over the years, management has sought to provide the highest level of resident comfort and environmental sustainability. Partnering with architects, designers and mechanical system installers that understand these priorities has lead the company to continuous growth.

At nearly all the Bridges locations, consulting engineer Wozny Barbar & Associates (WB&A) has been hired for the mechanical system design. The 27-year-old firm specializes in assisted living facilities, with an impressive list of projects completed throughout the Northeast.

“We have 37 employees,” said Casey Archacki, PE. “As the market has changed and grown, so has our stake in the industry. We’ve done work for EPOCH specifically since 2011.”

In 2016, construction began on the newest facility, Bridges by EPOCH at Sudbury (MA). With help from manufacturer’s representatives at Emerson Swan, WB&A specified a mechanical system that has performed exceptionally well at other EPOCH properties: a cooling tower and boiler system providing heating and cooling capacity to a variable-speed loop for water source heat pumps, along with an extensive ventilation system.

Comfort and control

“The heat pump systems provide a high level of control and zoning throughout the building,” said Archacki. “At EPOCH, comfort is the main priority, followed by efficiency and lifecycle cost.”

Bridges at Sudbury is a 45,000 square-foot, single-structure facility with 54 resident apartments. An 85-ton cooling tower and two redundant 650 MBH condensing boilers serve the collection of water source heat pumps. Whalen vertical-stack heat pumps are used in tenant rooms, while horizontal heat pumps made by Florida Heat Pump are used in common areas.

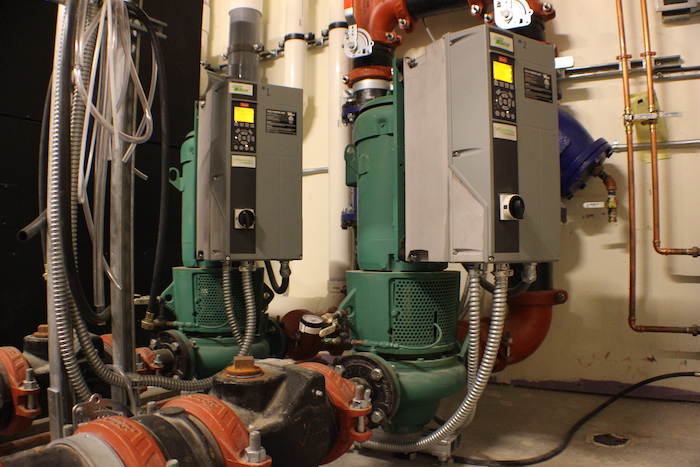

The building loop serving the heat pumps is served by a pair of redundant Taco SelfSensing pumps, with a max 210 GPM and 70 ft. head. The use of SelfSensing pumps eliminates the need for pressure sensors within the hydronic loop, and speeds up the commissioning and balancing process.

“To improve the indoor air quality of the building, the owners request that all of the spaces be mechanically ventilated,” said Archacki. “In order to accomplish this, all the bathroom exhaust has to be mechanically balanced with ventilation air. Since each resident has a private bathroom, this means that outdoor air and exhaust air requirements are quite high for the building. In order to maximize the energy load, we provided a single energy recovery ventilator to handle all of the outdoor and exhaust air.”

EPOCH has hired WB&A for numerous projects in part because the engineering firm comes highly recommended by architects. Their systems continuously perform. Each time they’ve approached a new EPOCH design, WB&A has drawn on the experience of Emerson Swan.

Smart choice in pumps

Emerson Swan has supplied the pumps, cooling towers and heat exchangers, along with assistance during specification, since WB&A was founded.

Emerson Swan has supplied the pumps, cooling towers and heat exchangers, along with assistance during specification, since WB&A was founded.

“Wozny Barbar is self-sufficient, but we help in any we can,” said Bill Arscott, sales engineer at Emerson Swan. “WB&A has been installing these heat pump systems before my time at Swan, and precedes the release of the Taco SelfSensing pumps that have simplified installation of the systems. Back then, conventional pumps with pressure sensors were used.”

Taco’s SelfSensing line of VFD-driven pumps not only eliminate the need for pressure sensors, but the VFDs are pre-programmed at the factory.

“The challenge we faced when using conventional circulators with sensors was picking a location for the sensor early on in the design phase,” said Archacki. “This was tough because the piping was subject to change, meaning sensor placement would no longer be ideal. Not needing sensors has been a big advantage.

Because Taco installs the VFDs on the pumps at the factory, on-site programming is not needed. The engineer provides a nominal pressure drop measurement, and the factory programs the units to 10 steps below nominal. Once installed, a balancing team fine tunes the pumps.

“We’ve always specified Taco in part because they’re a local company,” said Archacki. “When the SelfSensing product line came out, I attended a lunch-and-learn hosted by Rich Medairos at Taco. “That was several years ago, and we’ve now installed the pumps at nine properties without a single issue.”

Modulation

Because the SelfSensing line of pumps can sense and respond to pressure changes within a hydronic system, DDC controls are eliminated from the picture. The big advantage is that the capability is all found in a single pump, as opposed to fishing wires, paying the set-up and maintenance contract for controls, and installing pressure sensors throughout the loop.

Because the SelfSensing line of pumps can sense and respond to pressure changes within a hydronic system, DDC controls are eliminated from the picture. The big advantage is that the capability is all found in a single pump, as opposed to fishing wires, paying the set-up and maintenance contract for controls, and installing pressure sensors throughout the loop.

When compared to fixed-speed, centrifugal pumps – which are specified for maximum flow rate – the savings provided by SelfSensing pumps are even greater. Fixed-speed pumps spin literally non-stop, regardless of whether there’s a call or not. By slowing or stopping the pumps, literally millions of revolutions per heating season are eliminated. This dramatically extends the life of pumps, seals and bearings and translates into a very big savings in wear and tear.

A 1750 RPM design pump will save at least 225,000,000 cycles every heating season.

From a design standpoint, SelfSensing pumps provide more leeway in pump selection, since the pump will adjust to the need.

Continuing success

“At most senior living facilities, residents don’t pay utilities, so they expect a lot, and that typically means very warm spaces,” said Archacki. “In addition to the high ventilation rate, we must be able to maintain 80°F at an outdoor design temp of 0°F.

Bridges By EPOCH has considered installing a VRF system at one of the properties in place of the heat pump design, but the systems typically have lower performance in the middle of winter. Discharge air temperatures can drop, resulting in lower comfort levels.

“In general, natural gas costs in this area have been stable and very cheap when compared to electricity,” said Archacki. “Massachusetts pays some of the highest electricity rates in the country. This, along with high comfort levels, is one of the main reasons we continue installing heat pump systems for EPOCH.”

The success that EPOCH has had since its inception is evident. Roughly one new property is constructed and occupied each year. Currently, WB&A is designing systems for two coming EPOCH facilities simultaneously, one in MA and one in NY.

Wilo, a provider of pumps and pump solutions for water management, building services and groundwater, was proud to sponsor Thomas University’s ‘Camp STEMtastic’ this summer through the Wilo-Foundation. The camp is the University’s science and technology-focused summer program for young students, and the foundation has been an active sponsor since 2015. Wilo USA was pleased Read more

Wilo, a provider of pumps and pump solutions for water management, building services and groundwater, was proud to sponsor Thomas University’s ‘Camp STEMtastic’ this summer through the Wilo-Foundation. The camp is the University’s science and technology-focused summer program for young students, and the foundation has been an active sponsor since 2015.

The students pose alongside camp leaders and Wilo USA’s Director of Operations, Darren McGuire, after an afternoon at Wilo’s production facility in Thomasville, GA.

Wilo USA was pleased to welcome this year’s group of rising 8th grade student campers to its production facility in Thomasville, GA as part of the STEMtastic program. The theme for this year’s camp was ‘The Human Machine,’ and campers’ activities and learning experiences throughout the week focused on simple and complex machines related to how the systems in the human body function together to complete specific tasks.

The students toured the Wilo USA facility on the fourth day of the camp and learned about the complex machines and systems used in production, as well as how Wilo pumps work to treat water supply and sewage within cities’ infrastructure. The campers also participated in a hands-on activity led by Wilo USA’s Director of Operations, Darren McGuire, in which they worked in teams to assemble two versions of a simple circulation system. They then used a Wilo circulator to pump dyed water through the piping structures they created, demonstrating how the human circulation system functions.

Students prepare to test their team project using a Wilo circulator to pump dyed water through a simple piping system.

On the last day of the camp, campers’ friends and family members attended a reception in which the students gave a presentation highlighting the events of the week. The group enjoyed a demonstration of the students’ project for the week, which was to build a simple machine to complete a specific task. Wilo was proud to take an active role in the program again this year and looks forward to continuing community involvement. You can learn more about the Wilo-Foundation and their ongoing support of science, education, culture and sport at www.wilo-foundation.de/en.html.

Toronto—Armstrong Fluid Technology has announced the launch of a multifaceted Customer Loyalty Program designed to help North American contractors, wholesalers and sales representatives deepen their customer relationships. The Contractor Rewards program incentivizes plumbing and HVAC contractors for purchasing Armstrong products by providing them with points that can be redeemed for a variety of prizes ranging Read more

Toronto—Armstrong Fluid Technology has announced the launch of a multifaceted Customer Loyalty Program designed to help North American contractors, wholesalers and sales representatives deepen their customer relationships.

The Contractor Rewards program incentivizes plumbing and HVAC contractors for purchasing Armstrong products by providing them with points that can be redeemed for a variety of prizes ranging from vacations and tools to electronics, recreational equipment and more than 100,000 other valuable items.

The program also rewards wholesalers and Armstrong sales representatives with the opportunity to win valuable consumer electronic items for referring trade contractors, plumbers, builders and remodelers who are interested in purchasing select items from any of Armstrong’s 13 different product lines.

“We sponsored this program because it is designed to help our distribution channel grow their businesses, enhance customer relationships and build repeat sales,” says Lex van der Weerd, Armstrong CEO. “The Contractor Rewards program is also sponsored by other manufacturers so participating contractors can accumulate points for purchasing products from other companies as well.”

Armstrong products included in the promotion include specific models of circulators, pumps, valves, replacement parts and accessories.

Wilo USA announced an extended range of models for the Wilo-Stratos GIGA line of centrifugal pumps to include three and four inch models, bringing the total offering of the Wilo-Stratos GIGA line to 28 models. The Wilo-Stratos GIGA is a space-saving in-line circulator with ECM technology that is designed for use in hot water heating Read more

Wilo USA announced an extended range of models for the Wilo-Stratos GIGA line of centrifugal pumps to include three and four inch models, bringing the total offering of the Wilo-Stratos GIGA line to 28 models.

The Wilo-Stratos GIGA is a space-saving in-line circulator with ECM technology that is designed for use in hot water heating systems, air conditioning, closed cooling circuits, industrial circulation and solar and geothermal systems. The GIGA features a motor-powerhead combination which gives optimal control over the pump, up to 9 hp with motor efficiencies now in class IE5. The control range is up to three times as high as conventional electronically-controlled pumps, and there are multiple control modules available for integration with building management systems.

Don Kahn, Senior Product Manager says, “The combination of its high-efficiency EC motor, optimized hydraulic design and the ability to self-adjust to system demand makes it the most efficient in-line pump in its class. Coupled with the ‘Green Button’ technology and building communications options, commissioning of the pump cannot get any easier.”

With heads up to 167 ft and flows to 550 gpm, the GIGA also features high corrosion protection due to its cataphoretic coating, enabling it to withstand high pressure and weathering. The new ranges of the Wilo-Stratos GIGA are now available by contacting your local Wilo USA representative.

Complex hydronic systems are so 2008, at least according to Mechanical-Hub ProStaffer Andy Mickelson, who owns Mickelson Plumbing and Heating in Missoula, Mont. His three-man shop does plenty of high-end residential work, and even here—no—especially here, their recipe for success, serviceability and efficiency includes a heavy dose of “keep it simple.” On a custom home Read more

Complex hydronic systems are so 2008, at least according to Mechanical-Hub ProStaffer Andy Mickelson, who owns Mickelson Plumbing and Heating in Missoula, Mont. His three-man shop does plenty of high-end residential work, and even here—no—especially here, their recipe for success, serviceability and efficiency includes a heavy dose of “keep it simple.”

On a custom home, where some contractors may be tempted to stack the material list high and deep, Andy does the opposite. He takes a step back from the blueprints and figures out how to use the fewest components needed without any compromise. Numerous zones, DHW production, multiple supply temperatures and snowmelt loops can and are all handled without making things more complicated.

“There are a number of things you can do to keep systems simple,” said Mickelson. “I make sure to avoid ‘inadvertent’ redundancy: that is, two products that accomplish the same task.

Proper sizing of radiation, pipe, pumps and boilers accurately is obviously important, too. Picking a control system that accomplishes what you need and nothing more is helpful.

Another thing we began doing a few years ago—and have noticed an improvement since – is sizing and grouping our zones to the capacity of a specific pump, instead for creating a zone with no real parameters, and trying to find a pump that fits the zone or zone group.”

Like a round peg in a round hole, selecting your circulator first can save a lot of trouble, as well as the issues that come with over- or under-pumping a system.

Starting in late October of last year, Mickelson was hired for a job that would test his ability to “keep it simple.”

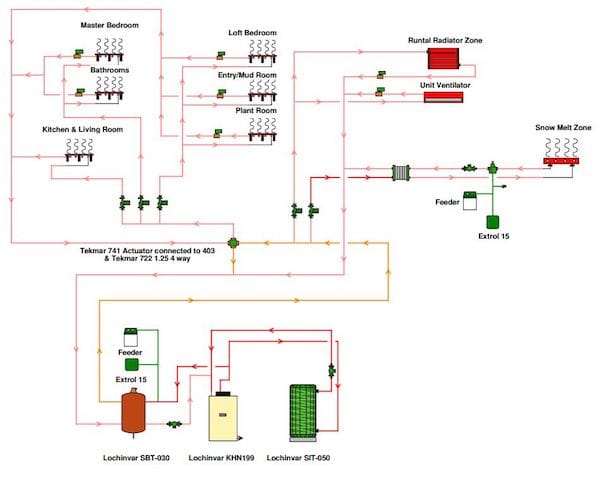

Mickelson’s work included installation of a mod-con boiler, seven zones of in-floor radiant, a hydronic unit ventilator, high-temp baseboard and 400 sq.-ft. of snowmelt.

Just out of town, the customer had purchased a nice lot with an older, 800-sq.-ft. home. The house was leveled and the basement foundation was re-used. The plan was to build a new 5,000-sq.-ft., two-story home on top of and around the original foundation.

Pick the pump first

“Like we do on all our jobs, I interviewed the homeowner long before we started the work, in order to really understand what they wanted,” said Mickelson. “Comfort was paramount, and budget not as much. So a thin concrete slab covers all radiant tubing, which is set at nine-inch centers.”

Before Mickelson started his loop layouts, he chose the Taco VT2218 variable speed circulator to serve all of the zones, with a total of six pumps. Additionally, Taco 007e single-speed ECM circulators are used on the 200 MBH fire-tube boiler and the indirect water heater.

“I like a Delta-T pump on a job like this, but another reason I used the VT2218 is for its broad pump curve, and we made use of it,” explained Mickelson. “It’s also very easy to program. Each radiant pump serves a group of zones. The zones are paired up according to the pump’s capacity, in terms of both head loss and flow rate. That way there aren’t any extra, underutilized circulators.”

Once the pump has been selected and the heat loss has been completed, the zones can be designed to fit the home. A common misconception about radiant circuits is that they must be as close to 300 feet long as possible, this just isn’t true. By dropping the length of each circuit, the head loss can be comfortably managed. The downfall to this is that the zone may require more circuits, but honestly the difference between five circuits and seven is minimal. It’s the same amount of tubing, no real noticeable increase in labor, just a larger manifold and a manageable head loss.

Low temp

Through zone valves, each pump supplies the appropriate amount of water and heat to a Watts Radiant stainless steel manifold, located remotely. Half-inch Watts RadiantPERT tubing was laid out before the gypcrete was poured.

“We chose the PERT instead of PEX because the radiant work was done throughout the winter. With spells of sub-zero weather, the increased flexibility of PERT was a huge benefit, especially considering our tight tube spacing.”

Because of the hydronic radiators, unit ventilator and snowmelt, the boiler maintains the buffer tank at 140°F at an outdoor design condition of -15°F. To make low temp water for the radiant zones, a Watts 4-way mixing valve with a tekmar 741 actuating motor was used. The 741 communicates with a tekmar 402 House Control in order to supply the exact radiant temperature need based on the outdoor temperature.

“The mixing valve sets the final delivery temp to all the low-temp zones,” said Mickleson. “It’s one of three elements at play here that really allow us to provide the exact temperature and flow rate to the radiant zones, so we’re really capitalizing on the primary/secondary piping, and squeezing every last ounce of comfort and efficiency out of the system. The other two elements are the outdoor reset on the higher temp boiler zones, and the variable-speed, Delta-T pumps. They all work hand in hand.”

The home has several areas with structural elements which made installing some of the tubing a challenging. Because of this, Mickelson had no choice but to run PEX supply and return piping through exterior walls. As a guard against the challenge of Montana winters, he wanted to run a glycol solution in the system. He installed a Neutra-Safe system feeder, which is an all-in-one reservoir, pump and control.

The home has several areas with structural elements which made installing some of the tubing a challenging. Because of this, Mickelson had no choice but to run PEX supply and return piping through exterior walls. As a guard against the challenge of Montana winters, he wanted to run a glycol solution in the system. He installed a Neutra-Safe system feeder, which is an all-in-one reservoir, pump and control.

High temp

The fourth and fifth VT2218 circulators serve the home’s three high-temp zones directly out of the buffer tank. In the basement, where the existing, uninsulated slab is still in place, Runtal baseboard was used in lieu of radiant tubing. Mickelson had considered ceiling radiant, but there wasn’t enough height to allow it. The circulator used for the baseboard zone also supplies water to the 12,000 BTU Smith Environmental unit ventilator in the garage attic.

The last variable-speed circulator serves as the snow melt system pump on the loop side of the brazed-plate heat exchanger. Mickelson uses a tekmar 654 Snowmelt Control to manage automatic operation and maintain a 25°F Delta-T across the 400 square-foot zone. This control features a snow and ice sensor that’s set in concrete when poured. The snowmelt loops also utilize a second Neutra-Safe System Feeder.

“Because of the components used and a thoughtful design, we’re covering five different loads with one boiler while installing it in a relatively tight space, all without being overly complicated,” said Mickelson.

Each pump supplies the appropriate amount of water and heat to a Watts Radiant stainless steel manifold.

“In the case of an emergency, I only have to deal with a single control system or one replacement pump,” he added. And with all that said, I can’t think of a quieter, more comfortable, or higher efficiency heating system.”

Mickelson is now going over a punch list, and looking forward to the feedback from the customer. He’s expecting rave reviews about the comfort level, and complete satisfaction when the owner receives their first propane bill.