Complex hydronic systems are so 2008, at least according to Mechanical-Hub ProStaffer Andy Mickelson, who owns Mickelson Plumbing and Heating in Missoula, Mont. His three-man shop does plenty of high-end residential work, and even here—no—especially here, their recipe for success, serviceability and efficiency includes a heavy dose of “keep it simple.” On a custom home Read more

Pumps

Complex hydronic systems are so 2008, at least according to Mechanical-Hub ProStaffer Andy Mickelson, who owns Mickelson Plumbing and Heating in Missoula, Mont. His three-man shop does plenty of high-end residential work, and even here—no—especially here, their recipe for success, serviceability and efficiency includes a heavy dose of “keep it simple.”

On a custom home, where some contractors may be tempted to stack the material list high and deep, Andy does the opposite. He takes a step back from the blueprints and figures out how to use the fewest components needed without any compromise. Numerous zones, DHW production, multiple supply temperatures and snowmelt loops can and are all handled without making things more complicated.

“There are a number of things you can do to keep systems simple,” said Mickelson. “I make sure to avoid ‘inadvertent’ redundancy: that is, two products that accomplish the same task.

Proper sizing of radiation, pipe, pumps and boilers accurately is obviously important, too. Picking a control system that accomplishes what you need and nothing more is helpful.

Another thing we began doing a few years ago—and have noticed an improvement since – is sizing and grouping our zones to the capacity of a specific pump, instead for creating a zone with no real parameters, and trying to find a pump that fits the zone or zone group.”

Like a round peg in a round hole, selecting your circulator first can save a lot of trouble, as well as the issues that come with over- or under-pumping a system.

Starting in late October of last year, Mickelson was hired for a job that would test his ability to “keep it simple.”

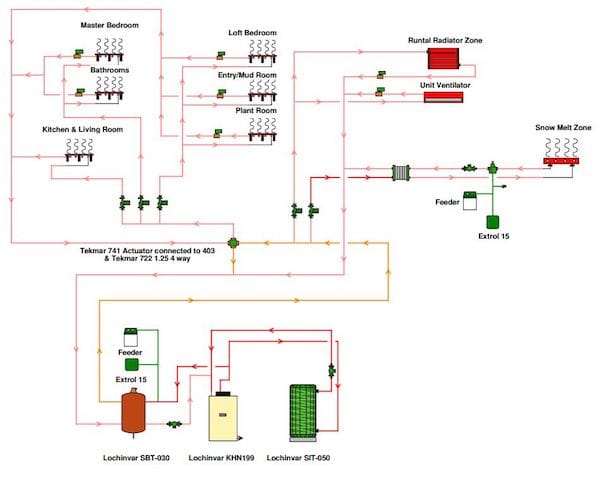

Mickelson’s work included installation of a mod-con boiler, seven zones of in-floor radiant, a hydronic unit ventilator, high-temp baseboard and 400 sq.-ft. of snowmelt.

Just out of town, the customer had purchased a nice lot with an older, 800-sq.-ft. home. The house was leveled and the basement foundation was re-used. The plan was to build a new 5,000-sq.-ft., two-story home on top of and around the original foundation.

Pick the pump first

“Like we do on all our jobs, I interviewed the homeowner long before we started the work, in order to really understand what they wanted,” said Mickelson. “Comfort was paramount, and budget not as much. So a thin concrete slab covers all radiant tubing, which is set at nine-inch centers.”

Before Mickelson started his loop layouts, he chose the Taco VT2218 variable speed circulator to serve all of the zones, with a total of six pumps. Additionally, Taco 007e single-speed ECM circulators are used on the 200 MBH fire-tube boiler and the indirect water heater.

“I like a Delta-T pump on a job like this, but another reason I used the VT2218 is for its broad pump curve, and we made use of it,” explained Mickelson. “It’s also very easy to program. Each radiant pump serves a group of zones. The zones are paired up according to the pump’s capacity, in terms of both head loss and flow rate. That way there aren’t any extra, underutilized circulators.”

Once the pump has been selected and the heat loss has been completed, the zones can be designed to fit the home. A common misconception about radiant circuits is that they must be as close to 300 feet long as possible, this just isn’t true. By dropping the length of each circuit, the head loss can be comfortably managed. The downfall to this is that the zone may require more circuits, but honestly the difference between five circuits and seven is minimal. It’s the same amount of tubing, no real noticeable increase in labor, just a larger manifold and a manageable head loss.

Low temp

Through zone valves, each pump supplies the appropriate amount of water and heat to a Watts Radiant stainless steel manifold, located remotely. Half-inch Watts RadiantPERT tubing was laid out before the gypcrete was poured.

“We chose the PERT instead of PEX because the radiant work was done throughout the winter. With spells of sub-zero weather, the increased flexibility of PERT was a huge benefit, especially considering our tight tube spacing.”

Because of the hydronic radiators, unit ventilator and snowmelt, the boiler maintains the buffer tank at 140°F at an outdoor design condition of -15°F. To make low temp water for the radiant zones, a Watts 4-way mixing valve with a tekmar 741 actuating motor was used. The 741 communicates with a tekmar 402 House Control in order to supply the exact radiant temperature need based on the outdoor temperature.

“The mixing valve sets the final delivery temp to all the low-temp zones,” said Mickleson. “It’s one of three elements at play here that really allow us to provide the exact temperature and flow rate to the radiant zones, so we’re really capitalizing on the primary/secondary piping, and squeezing every last ounce of comfort and efficiency out of the system. The other two elements are the outdoor reset on the higher temp boiler zones, and the variable-speed, Delta-T pumps. They all work hand in hand.”

The home has several areas with structural elements which made installing some of the tubing a challenging. Because of this, Mickelson had no choice but to run PEX supply and return piping through exterior walls. As a guard against the challenge of Montana winters, he wanted to run a glycol solution in the system. He installed a Neutra-Safe system feeder, which is an all-in-one reservoir, pump and control.

The home has several areas with structural elements which made installing some of the tubing a challenging. Because of this, Mickelson had no choice but to run PEX supply and return piping through exterior walls. As a guard against the challenge of Montana winters, he wanted to run a glycol solution in the system. He installed a Neutra-Safe system feeder, which is an all-in-one reservoir, pump and control.

High temp

The fourth and fifth VT2218 circulators serve the home’s three high-temp zones directly out of the buffer tank. In the basement, where the existing, uninsulated slab is still in place, Runtal baseboard was used in lieu of radiant tubing. Mickelson had considered ceiling radiant, but there wasn’t enough height to allow it. The circulator used for the baseboard zone also supplies water to the 12,000 BTU Smith Environmental unit ventilator in the garage attic.

The last variable-speed circulator serves as the snow melt system pump on the loop side of the brazed-plate heat exchanger. Mickelson uses a tekmar 654 Snowmelt Control to manage automatic operation and maintain a 25°F Delta-T across the 400 square-foot zone. This control features a snow and ice sensor that’s set in concrete when poured. The snowmelt loops also utilize a second Neutra-Safe System Feeder.

“Because of the components used and a thoughtful design, we’re covering five different loads with one boiler while installing it in a relatively tight space, all without being overly complicated,” said Mickelson.

Each pump supplies the appropriate amount of water and heat to a Watts Radiant stainless steel manifold.

“In the case of an emergency, I only have to deal with a single control system or one replacement pump,” he added. And with all that said, I can’t think of a quieter, more comfortable, or higher efficiency heating system.”

Mickelson is now going over a punch list, and looking forward to the feedback from the customer. He’s expecting rave reviews about the comfort level, and complete satisfaction when the owner receives their first propane bill.

Taco Comfort Solutions has added new features and capabilities to their large 00e VR ECM, wet rotor commercial circulator line designed for chilled and hot water applications. Available in four sizes (VR 15-3, 20-3, 25-3 and 30-3), the sensorless 00e VR line provides differential head pressures up to 42 ft. and flows up to 360 Read more

Taco Comfort Solutions has added new features and capabilities to their large 00e VR ECM, wet rotor commercial circulator line designed for chilled and hot water applications. Available in four sizes (VR 15-3, 20-3, 25-3 and 30-3), the sensorless 00e VR line provides differential head pressures up to 42 ft. and flows up to 360 GPM.

Taco Comfort Solutions has added new features and capabilities to their large 00e VR ECM, wet rotor commercial circulator line designed for chilled and hot water applications. Available in four sizes (VR 15-3, 20-3, 25-3 and 30-3), the sensorless 00e VR line provides differential head pressures up to 42 ft. and flows up to 360 GPM.

Designed around customer demands for functional simplicity, upgraded feature sets of the new VR models will include simple user interface to enable setting changes on the face of the pump, eliminating the need for laptop setup. Also, real-time performance readouts for flow, power consumption, speed and head values.

Taco’s new VR circulators also offer self-sensing dynamic auto (factory default), proportional and constant pressure, plus manual variable speed modes for maximum application flexibility. On board 0-10Vdc two way control adjusts speed or head to meet system demands from external control inputs. And ModBus control and performance feedback link with advanced building management/Building Automation Systems.

New VR circulators also provide RJ 45 input/output for ease of networking, relay outputs for remote monitoring, digital inputs for external enable/disabling, and simple main/standby and parallel pump operation via standard Ethernet cabling.

For more information, please visit www.TacoComfort.com.

Taco’s now-expanded ECM, wet rotor Viridian line includes the VR3452 high efficiency wet rotor variable speed circulator for chilled and hot water applications, offering up to 34 feet of shut-off head and 52 gpm flow. All settings are accomplished with the user-friendly interface. The permanent magnet ECM motor saves up to 85% of the electrical Read more

Taco’s now-expanded ECM, wet rotor Viridian line includes the VR3452 high efficiency wet rotor variable speed circulator for chilled and hot water applications, offering up to 34 feet of shut-off head and 52 gpm flow. All settings are accomplished with the user-friendly interface. The permanent magnet ECM motor saves up to 85% of the electrical energy compared to conventional pumps.

The circulator offers:

• Auto mode (default)

• Proportional pressure control

• Constant pressure control

• Constant speed

• Night setback turndown

• Available in 115 or 230 volts

The optional communication module provides: Ethernet and Modbus RTU communication, analog control input 0 – 10 V, three analog inputs/outputs, one relay output, main and standby operation.

Bell & Gossett announces its 2015 third quarter Little Red Schoolhouse seminar schedule for in-person training. The training center’s seminars provide systems design training to engineers, wholesalers and contractors in the plumbing and hydronic heating and cooling industries. Little Red Schoolhouse Opened in 1954, the Little Red Schoolhouse offers seminars covering a wide range of Read more

Bell & Gossett announces its 2015 third quarter Little Red Schoolhouse seminar

schedule for in-person training. The training center’s seminars provide systems design training to engineers, wholesalers and contractors in the plumbing and hydronic heating and cooling industries.

Little Red Schoolhouse Opened in 1954, the Little Red Schoolhouse offers seminars covering a wide range of topics tailored to different occupations in the industry. Our Little Red Schoolhouse, a completely equipped learning center, has trained more than 60,000 engineers, contractors and installers in the proper design, installation and maintenance

of hydronic and steam systems.

Little Red Schoolhouse third quarter schedule

• Design & Application of Water Based HVAC Systems Seminar* September 28-30

• Service & Maintenance of Water Based HVAC Systems Seminar October 5-7

• Modern Hydronic Heating Systems- Basic Seminar* October 12-14

• Modern Hydronic Heating Systems- Advanced Seminar* October 19-21

• Design & Application of Water Based HVAC Systems Seminar* November 9-11

• Large Chilled Water System Design Seminar* November 16-18

• Steam System Design & Application Seminar December 7-9

*Seminar approved by GBCI to provide credit toward the credential maintenance requirements of the LEED Associate and LEED AP certifications

Online education

Bell & Gossett’s commitment to education continues with virtual curriculum. The Online Little Red Schoolhouse training and educational programming is available to a global audience. Programming begins with introductory courses on centrifugal pump fundamentals and piping systems. These courses are intended to complement the more in-depth, hands-on experience our students get through in-person courses.

For continuing education credit information, seminar descriptions, representative information and enrollment, visit www.bellgossett.com/training-education.

To sign up for seminars via the Online Little Red Schoolhouse, visit: http://training.bellgossett.com/.

When Eric and John asked me to write a blog post on “Hydronics 101,” I have to admit I was a bit overwhelmed. Where on earth do you start? There’s boiler piping, pipe sizing, circulator selection, heat emitter selection, controls wiring, and so on. There are so many avenues to take when it comes to Read more

When Eric and John asked me to write a blog post on “Hydronics 101,” I have to admit I was a bit overwhelmed. Where on earth do you start? There’s boiler piping, pipe sizing, circulator selection, heat emitter selection, controls wiring, and so on.

There are so many avenues to take when it comes to “Hydronics 101” that choosing a starting point becomes quite a daunting task.

But then I thought of one of the very first training classes I ever did.

It was 1995 during a full-day program on radiant floor heating. We were going through the process of radiant design — figuring out installation method, tube spacing and water temperature. We were looking over charts and graphs to make heads or tails out of this radiant job when a fellow in the back of the room raised his hand.

“Don’t you have computer software that figures all this stuff out?”

Yep, we do.

“Then why are you wasting our time telling us all this? Just give us the software and we can go home.”

Ummm, it doesn’t quite work that way.

Design software, whether it’s for hydronics or forced air, is really nothing more than a fancy calculator. It does the arithmetic for you, and that’s about it. It doesn’t think for you, it doesn’t make decisions for you and it doesn’t tell you if you’ve input the wrong data.

It’s a calculator.

That’s it.

I like to ask folks in my classes how many of them have been formally trained in how to perform heat loss calculations. We call it “doing the math.”

As the years have gone by, fewer and fewer people raise their hands. No one’s teaching heat loss anymore, and I think it’s a shame. Knowing the actual heating load of a house or of a zone is the real “starting point” for beginning hydronics or for advanced hydronics.

How can you size a boiler if you don’t know the load? You can guess, but it’s just that: a guess. You can base your load on a standard BTU-per-square-foot multiplier, but that’s not a heat loss calculation. That’s just a guess with better PR. You can even measure the radiation, multiply by whatever multiplier you care to use and call that the load. But all that tells you is how much radiation is installed.

Good to know, but it doesn’t tell you the actual load of the house.

There’s no way around it: a good old-fashioned heat loss calculation is the only way of getting anywhere close to what the actual load of the house really is. Are “by-the-book” heat loss calculations 100% accurate? Nope — there’s so much fudge built in to the calculation methods out there that it’s a wonder we’re not all diabetic. But they’re still better than guessing.

During one of Taco’s Heat Loss classes a while back, the class was presented with a set of blueprints for normal, stick-framed house. There was nothing special about this house. It wasn’t super-insulated with super-low E windows or anything. It was a basic 2200 square foot ranch, with an outdoor design temperature of 7 degrees above Zero.

I asked the group, based on their years of knowledge and experience, to come up with their best, most accurate estimate for the heating load of the house. Their responses ranged anywhere from 55,000 BTUH on the low end to 125,000 BTUH on the high end.

The class then worked through an I-B-R based heat-loss analysis using the H-22 Heat Loss Design Guide (find it on Amazon under “Freaking Awesome Heat Loss Book!”). Using charts, graphs and real live, honest-to-goodness math, the class calculated the heat loss of that house to be a whopping 31,000 BTUH.

Well ain’t that a kick in the head!

Bottom line gang: any fundamentally sound hydronics system starts with the math. Heat load allows us to size our boiler and all of our piping as accurately as possible, which can have a major impact on materials costs. And only when we know the heating load and the size and length of the pipe that heat has to go through can we figure out what we need for a circulator, because load determines flow and pipe size and length determine head loss.

And weather impacts it all.

From there we can look at all the different types of circulators (steep curve, flat curve, single-speed, 3-speed, variable speed, Delta-T, Delta-P) and try to determine which one best fits the job we’re looking at – and no, there’s NO SUCH THING as “the only circulator you’ll ever need.” That’s a load of hogwash.

So where does “Hydronics 101” start? It must start with an accurate idea of what you’re trying to accomplish, which is to make sure this structure heats on what’s commonly referred to as “the coldest day of the year.” Now, if you’re simply replacing a dead circulator, there’s precious little math that needs to be done (but you still have to know about circulators and their impact on systems – that’s a future segment). But if you’re replacing a boiler or actually starting from scratch, the only right way to start is with a pad of paper, a scaled ruler, a pencil and a calculator. If John and Eric invite me back, we’ll walk through simple heat loss calculations done the old fashioned way. Software will do it quicker, but in order for software to be a tool and not a convenience item, it’s important to know why it came up with the numbers that it did.

As my old man used to say, “Knowing how is good, but know why is better. Because those who know ‘how’ will always work for those who know ‘why.’”

John Barba is training manager for Taco Inc.

John Barba is training manager for Taco Inc.